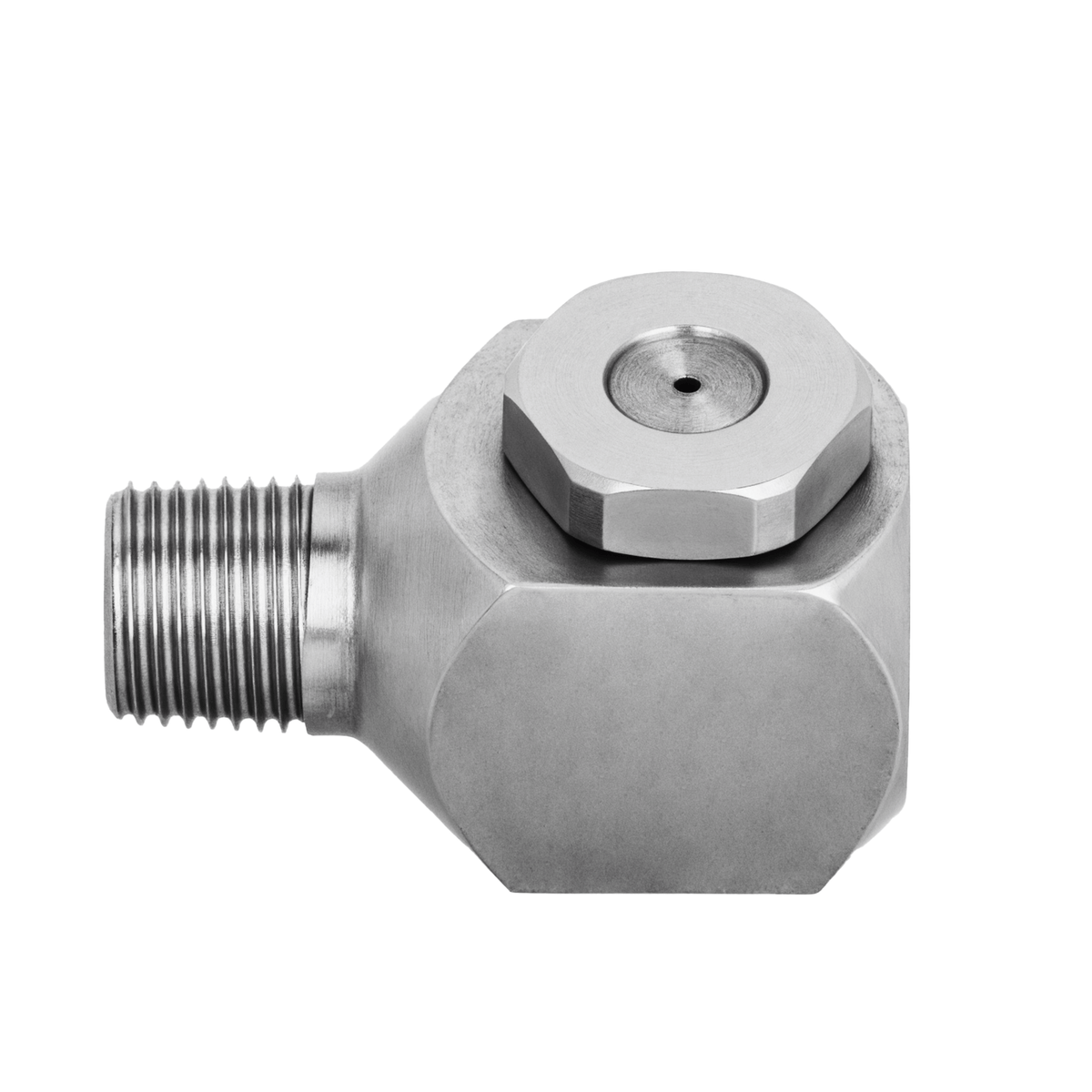

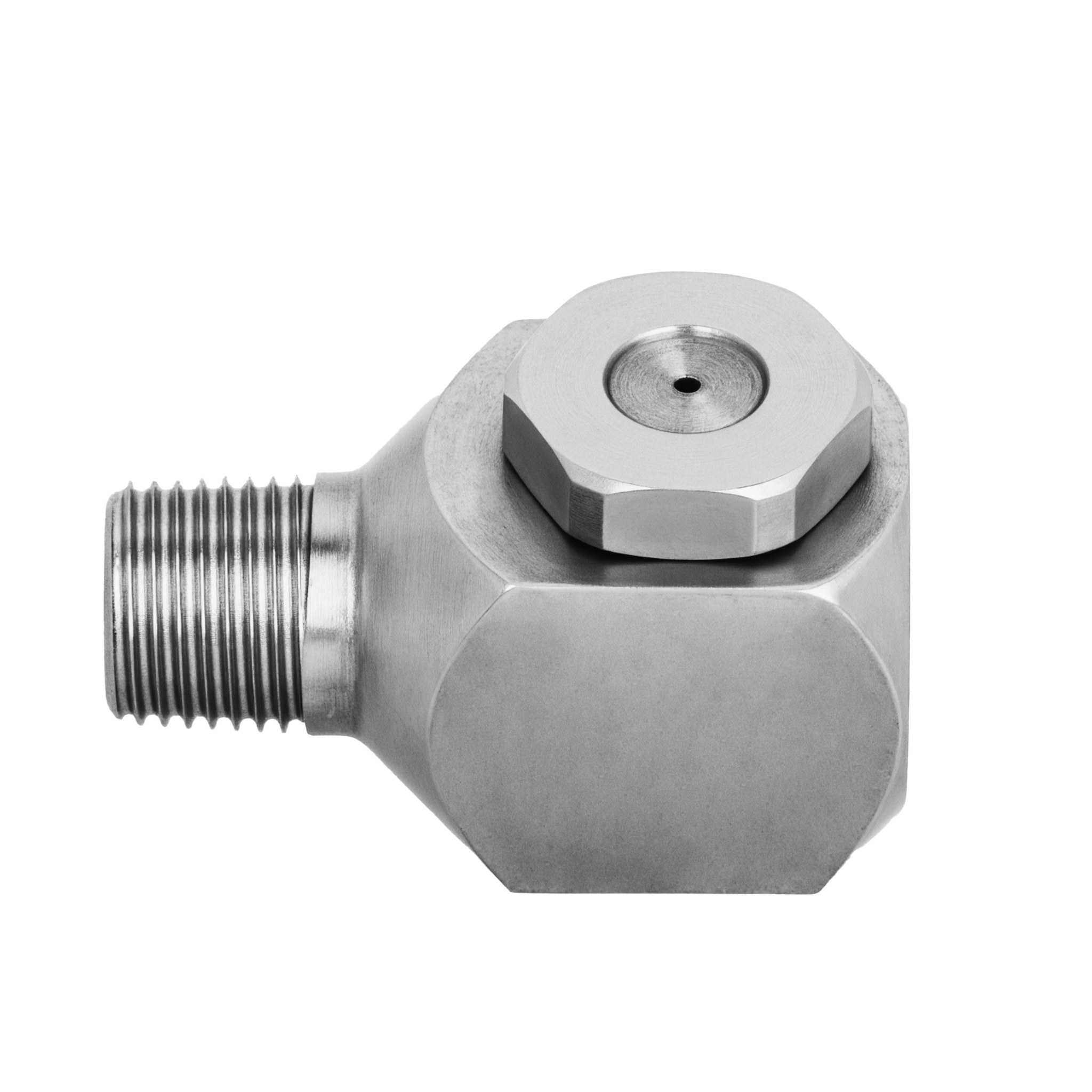

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 3-3W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 303/304 stainless steel |

| Orifice Diameter. Nom. (mm) | 2.4 |

| Orifice Diameter. Nom. (in) | 0.109 |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 30.5 |

| Length (in) | 1.188 |

| Inlet Dia. Nom. (in) | 0.094 |

| Max. Free Passage Dia. (mm) | 2.8 |

Description

Product Overview

Inside the Energy line's specialty applications stage, a production technician relies on the NPBX-3-3W-1/8-SS to deliver consistent spray coverage critical for process stability. Constructed from 303/304 stainless steel, the nozzle withstands corrosive environments while producing a hollow cone spray pattern that ensures uniform distribution. This precision design supports accurate fluid atomization, optimizing cooling rates and material treatment outcomes. The technician integrates the nozzle seamlessly with existing systems via its 1/8-inch inlet, maintaining operational efficiency and reducing maintenance downtime.

Applications

In cooling & quenching operations, the nozzle enables precise temperature control by delivering a consistent hollow cone spray for effective heat dissipation. Additionally, it plays a role in dust & pollution control by atomizing fluids evenly, aiding in particulate suppression and improving air quality within the process environment.

Industries

The NPBX-3-3W-1/8-SS is favored across industries such as automotive, chemical processing, and steel & metals due to its durability and consistent spray performance under harsh conditions. Building materials, breweries & wineries, and meat & poultry sectors also employ this nozzle to enhance fluid delivery in manufacturing and assembly processes where uniform application is essential.