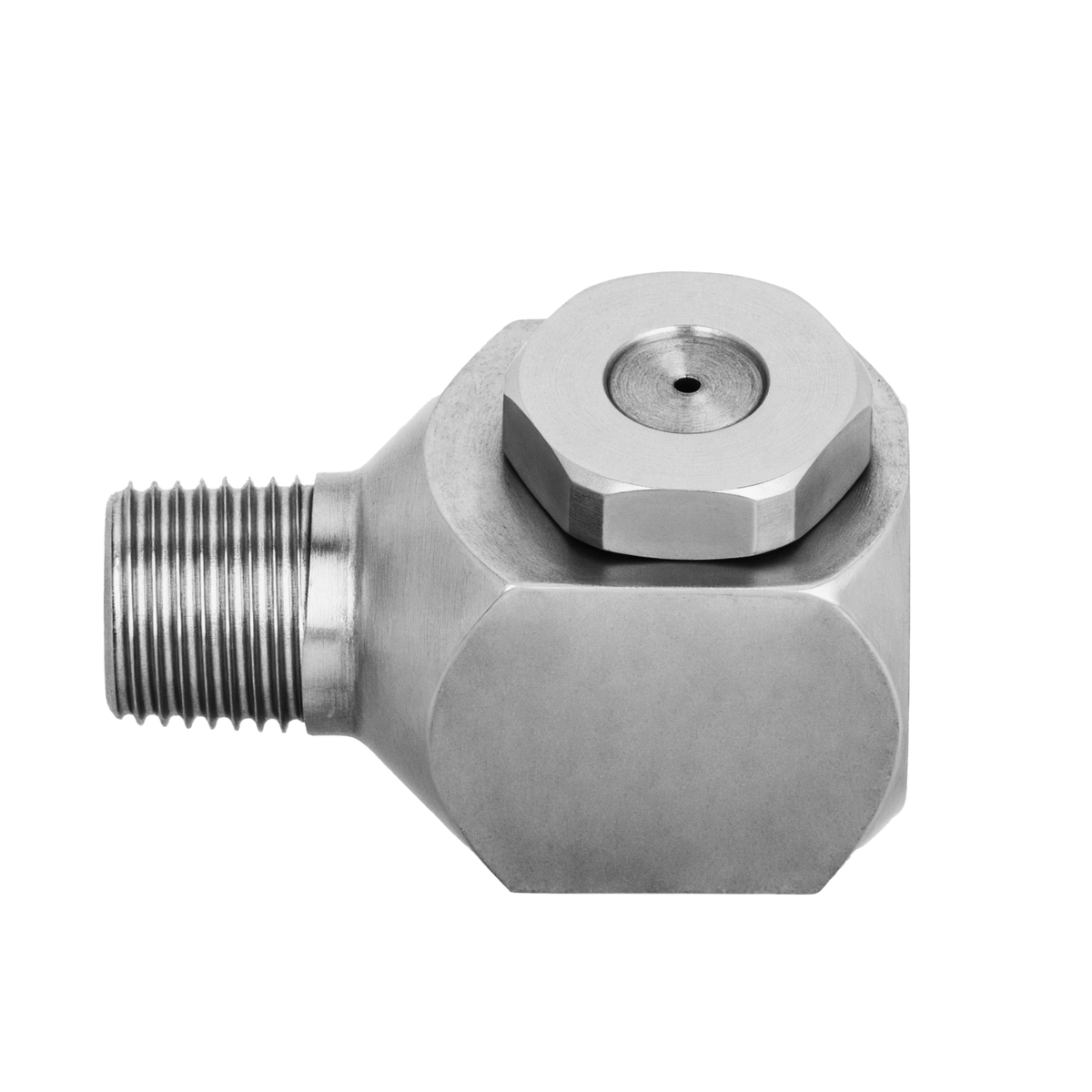

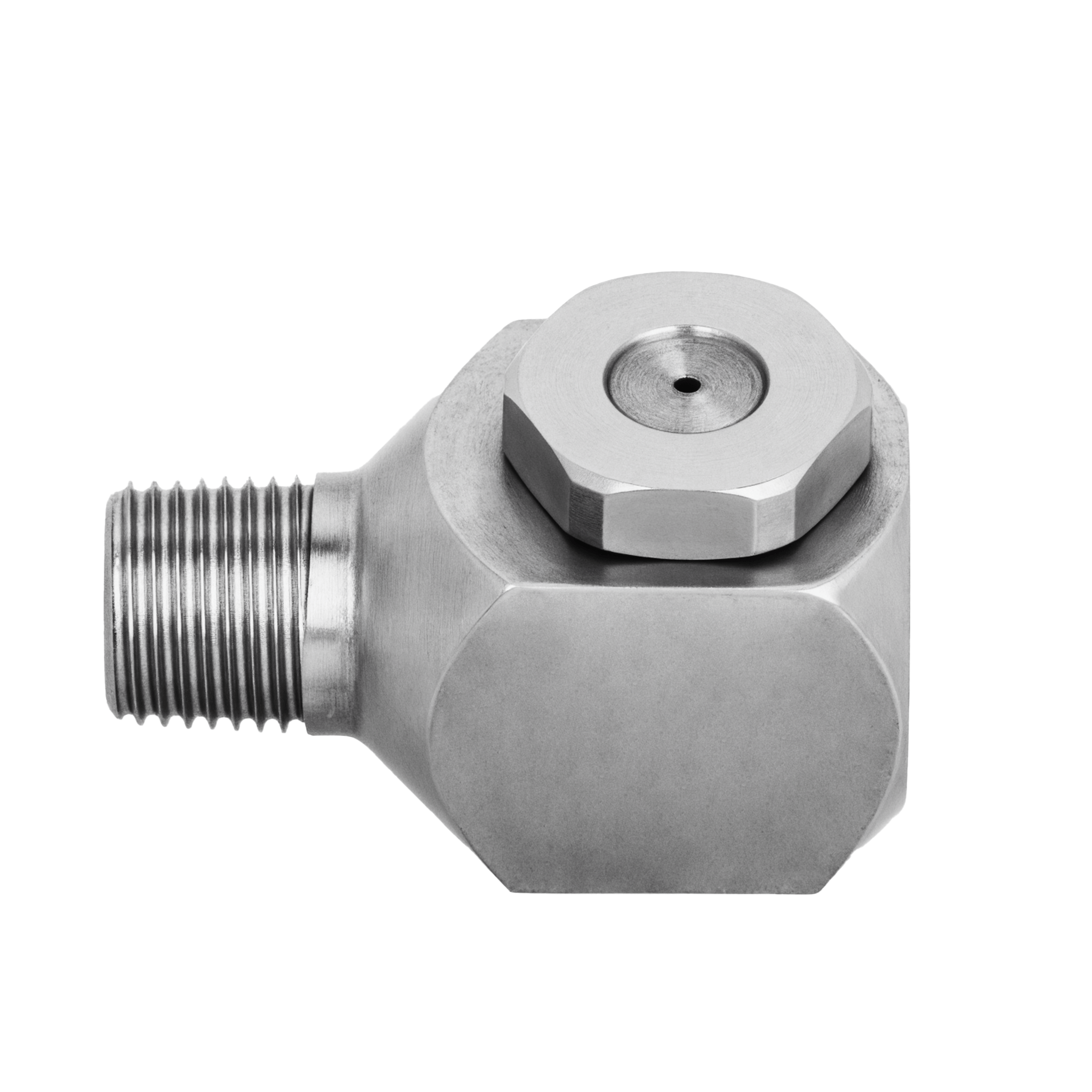

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 15-15W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 6 |

| Orifice Diameter. Nom. (in) | 0.219 |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 35 |

| Length (in) | 1.375 |

| Inlet Dia. Nom. (in) | 0.234 |

| Max. Free Passage Dia. (mm) | 5.6 |

Description

Product Overview

A process engineer in the steel & metals facility uses the NPBX-15-15W-1/4-316 during dust & pollution control to ensure consistent dispersion of particulate matter. The 316L stainless steel construction provides resistance to corrosion in harsh environments, extending nozzle service life. Its hollow cone spray pattern delivers uniform coverage, improving capture efficiency and reducing airborne contaminants. Installation involves connecting the 1/4-inch inlet to existing piping, allowing precise control of flow rates and spray angles.

Applications

In dust & pollution control applications, the nozzle supports effective suppression of airborne particles, minimizing environmental emissions and enhancing workplace safety. Additionally, its uniform spray pattern is valuable for humidification & conditioning processes, where consistent moisture distribution is critical to maintaining product quality and process stability.

Industries

The NPBX-15-15W-1/4-316 is favored across automotive, building materials, chemical processing, Energy, steel & metals, breweries & wineries, cement, manufacturing & assembly, and meat & poultry sectors due to its durability and reliable spray characteristics. These industries benefit from its corrosion resistance and adaptability to a range of operational demands, including cooling, dust suppression, and conditioning applications.