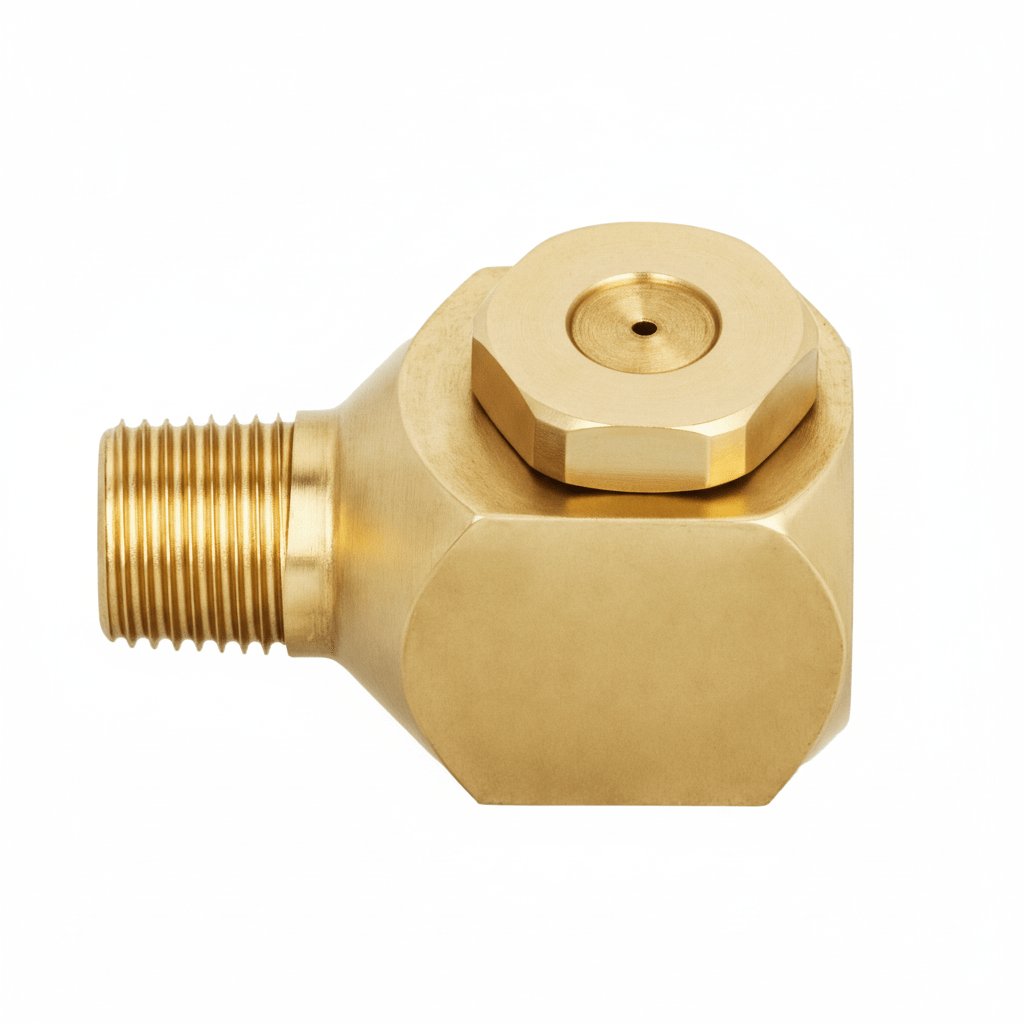

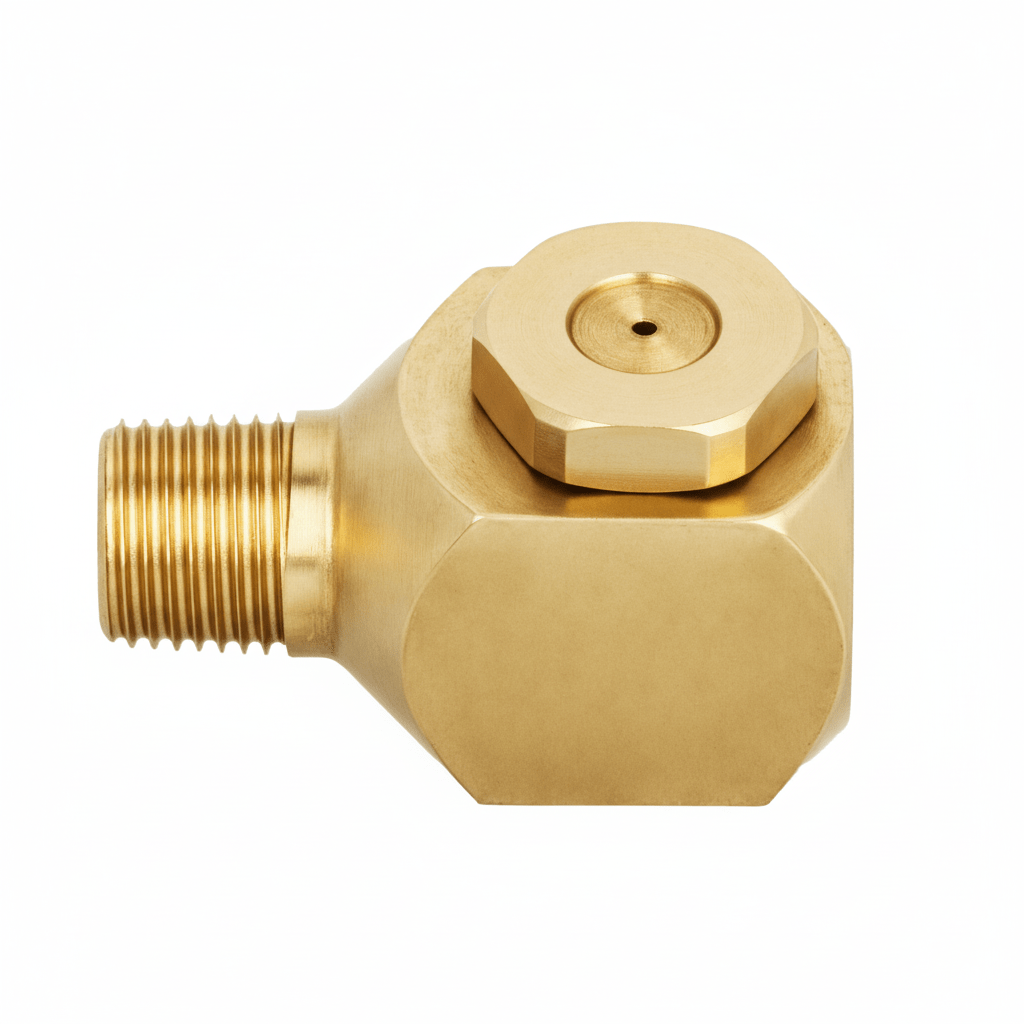

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 1-5W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 1.6 |

| Orifice Diameter. Nom. (in) | 0.125 |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 35 |

| Length (in) | 1.375 |

| Inlet Dia. Nom. (in) | 0.063 |

| Max. Free Passage Dia. (mm) | 3.2 |

Description

Product Overview

Inside the chemical processing line's cooling & quenching stage, a maintenance supervisor relies on the NPBX-1-5W-1/4 to deliver consistent spray coverage that protects equipment from thermal stress. Constructed from brass, the nozzle resists corrosion while producing a hollow cone spray pattern that ensures uniform fluid distribution. The precision design allows for repeatable performance, reducing downtime and optimizing cooling efficiency. Installation involves connecting the 1/4-inch inlet securely to the system, enabling controlled flow rates that meet operational specifications.

Applications

In cooling & quenching processes, the NPBX-1-5W-1/4 provides steady, uniform sprays that prevent overheating and material deformation. Additionally, its consistent output supports dust & pollution control efforts by minimizing airborne particulates downstream in the production environment.

Industries

Sectors such as automotive, building materials, and chemical processing utilize the nozzle for its reliability under varied operating conditions. Energy, steel & metals, breweries & wineries, cement, manufacturing & assembly, and meat & poultry industries also select this nozzle to maintain precise fluid application, which is critical for maintaining process stability and product quality.