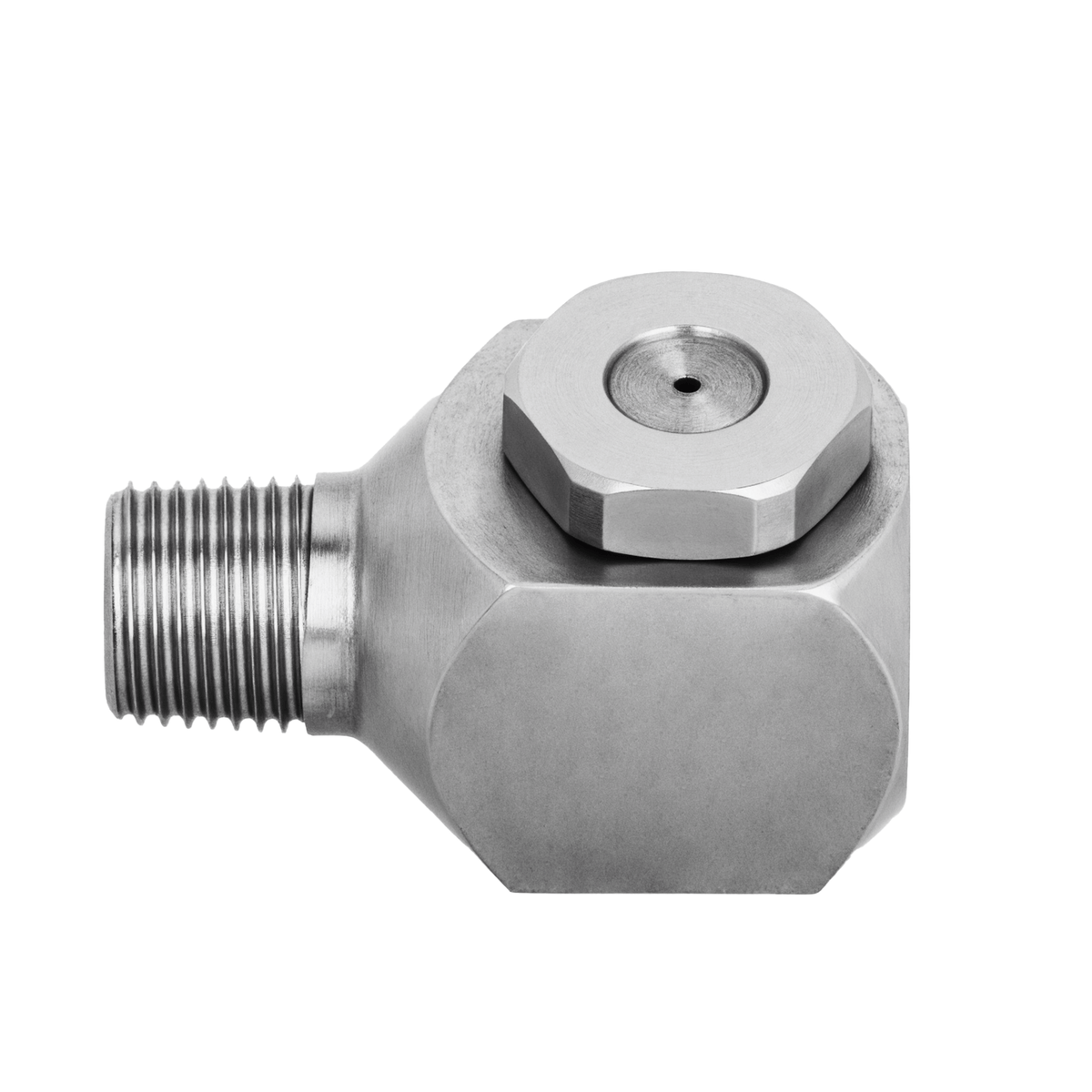

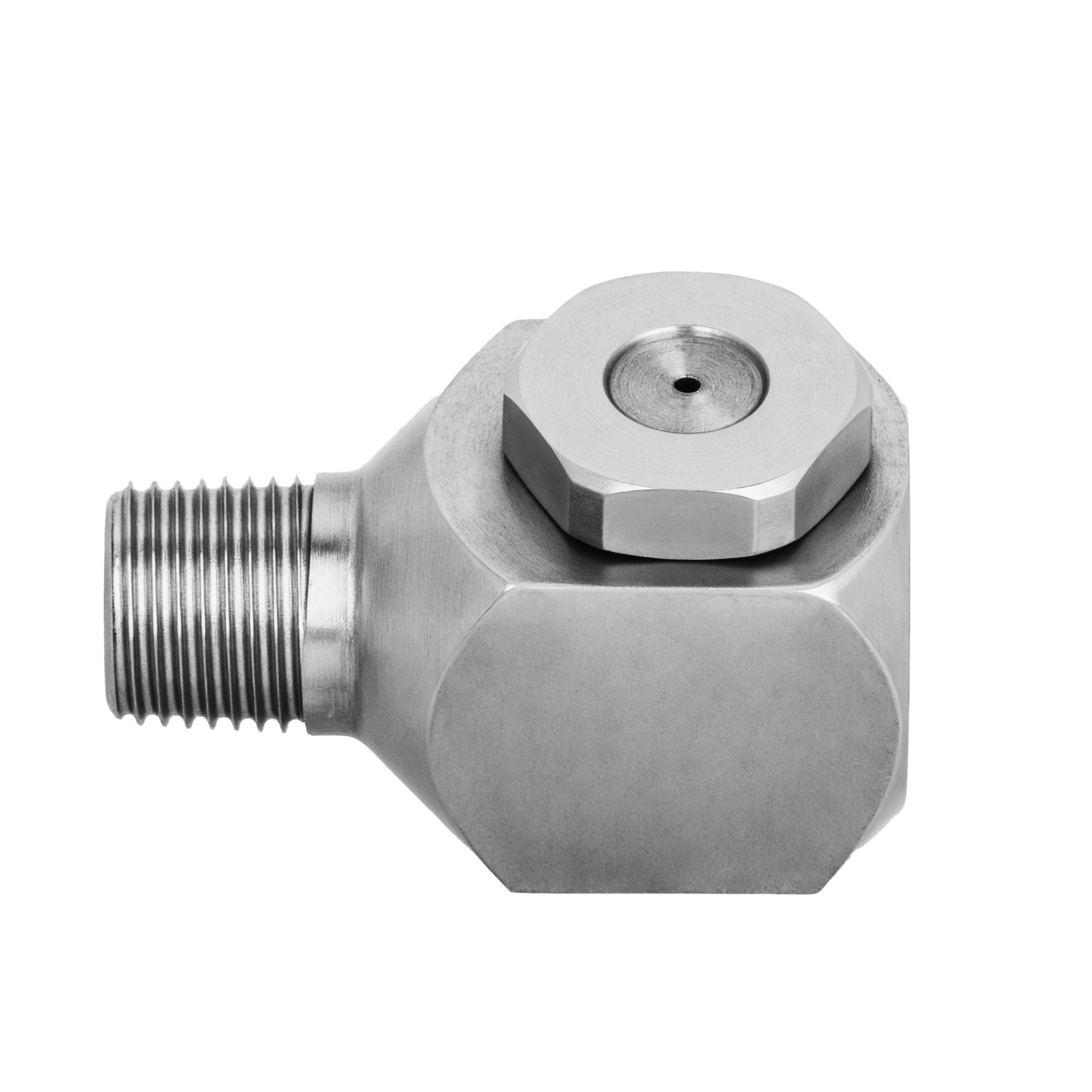

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 1-1W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 1.6 |

| Orifice Diameter. Nom. (in) | 0.063 |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 30.5 |

| Length (in) | 1.188 |

| Inlet Dia. Nom. (in) | 0.063 |

| Max. Free Passage Dia. (mm) | 1.6 |

Description

Product Overview

When meat & poultry crews manage humidification & conditioning, the NPBX-1-1W-1/8-316 lets each production technician install a corrosion-resistant nozzle that maintains consistent spray quality across the entire coverage area. Constructed from 316L stainless steel, this precision hollow cone nozzle delivers a uniform droplet distribution with a 1/8-inch inlet, ensuring reliable operation in demanding environments. Operators can expect minimized wear and stable spray performance over extended production cycles, which supports process control and hygiene standards. The NPBX-1-1W-1/8-316 contributes to efficient moisture regulation critical for product quality.

Applications

In cooling & quenching processes, the nozzle provides consistent spray patterns that help regulate temperature across metal surfaces, reducing thermal stress and enhancing material properties. Dust & pollution control benefits from the precise hollow cone spray, which effectively captures airborne particles, improving air quality and compliance with environmental regulations.

Industries

Automotive, chemical processing, and steel & metals sectors often rely on this nozzle for its corrosion resistance and uniform spray distribution, which are essential in both manufacturing and assembly lines. Additionally, building materials, breweries & wineries, and cement operations value the nozzle's durability and performance in humidification & conditioning tasks, where precise