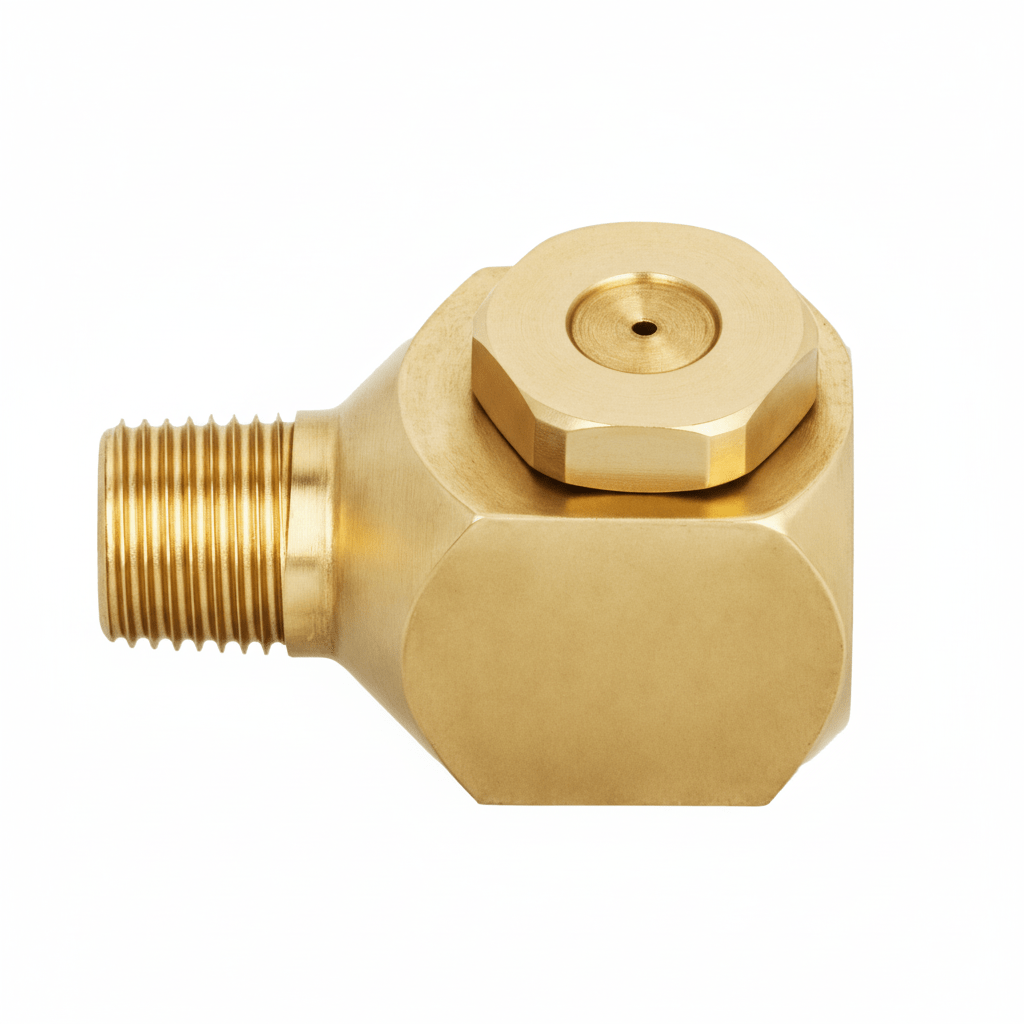

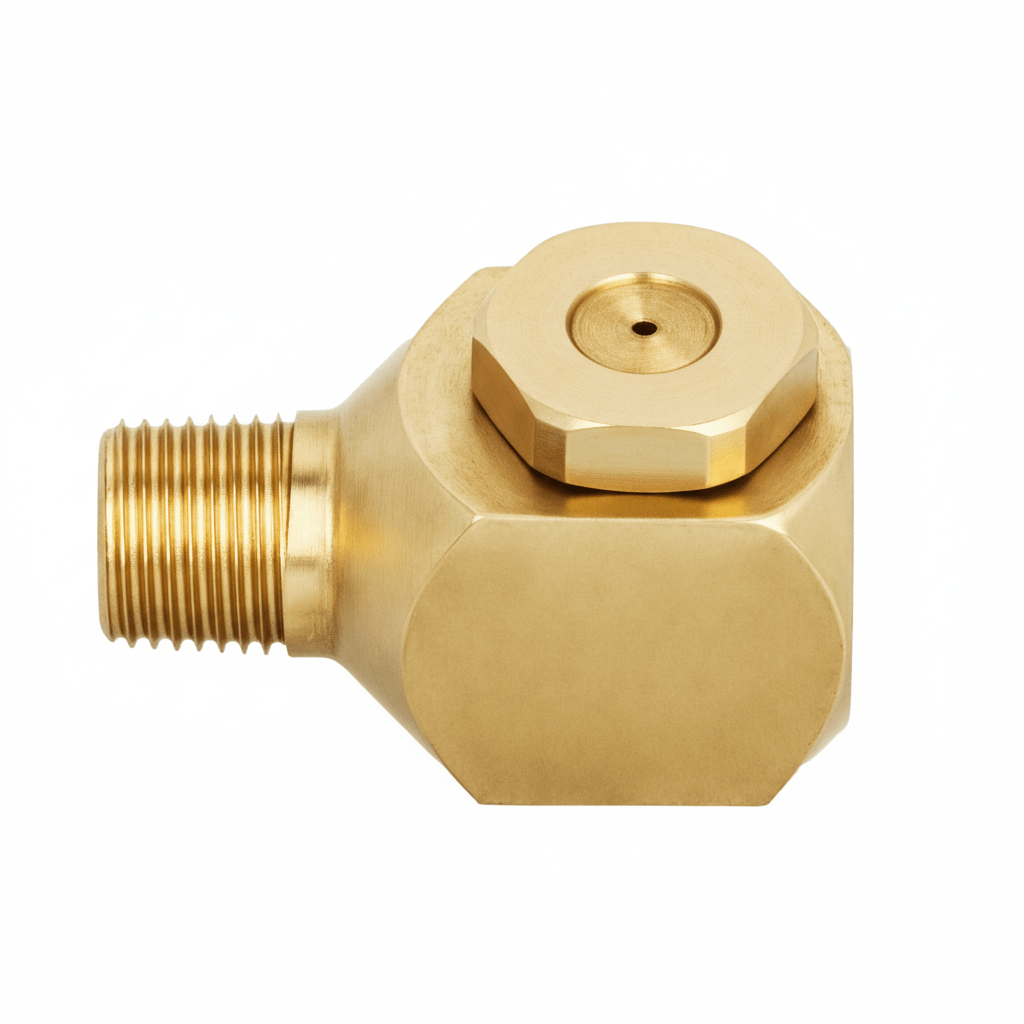

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 1-1W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 1.6 |

| Orifice Diameter. Nom. (in) | 0.063 |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 35 |

| Length (in) | 1.375 |

| Inlet Dia. Nom. (in) | 0.063 |

| Max. Free Passage Dia. (mm) | 1.6 |

Description

Product Overview

When Energy crews manage cooling & quenching, the NPBX-1-1W-1/4 lets each production technician achieve consistent fluid distribution through its precision hollow cone spray pattern. Constructed from brass, this nozzle resists corrosion, maintaining stable performance in harsh industrial environments. Operators rely on the 1/4-inch inlet size for secure connections to existing piping systems, ensuring reliable flow rates. The NPBX-1-1W-1/4 supports process control by delivering uniform coverage, which helps optimize temperature regulation and minimizes downtime.

Applications

In cooling & quenching operations, the uniform spray pattern prevents hotspots and improves material quality by controlling metal temperatures precisely. Additionally, dust & pollution control applications benefit from consistent atomization, reducing airborne particulates and aiding regulatory compliance.

Industries

Automotive, steel & metals, and chemical processing industries favor this nozzle for its durability and consistent spray characteristics, which support rigorous production demands. Breweries & wineries, cement, and manufacturing & assembly operations also utilize the NPBX-1-1W-1/4 to maintain process efficiency where fluid control is critical.