Product Parameters

| Product Family | Hollow Cone |

|---|---|

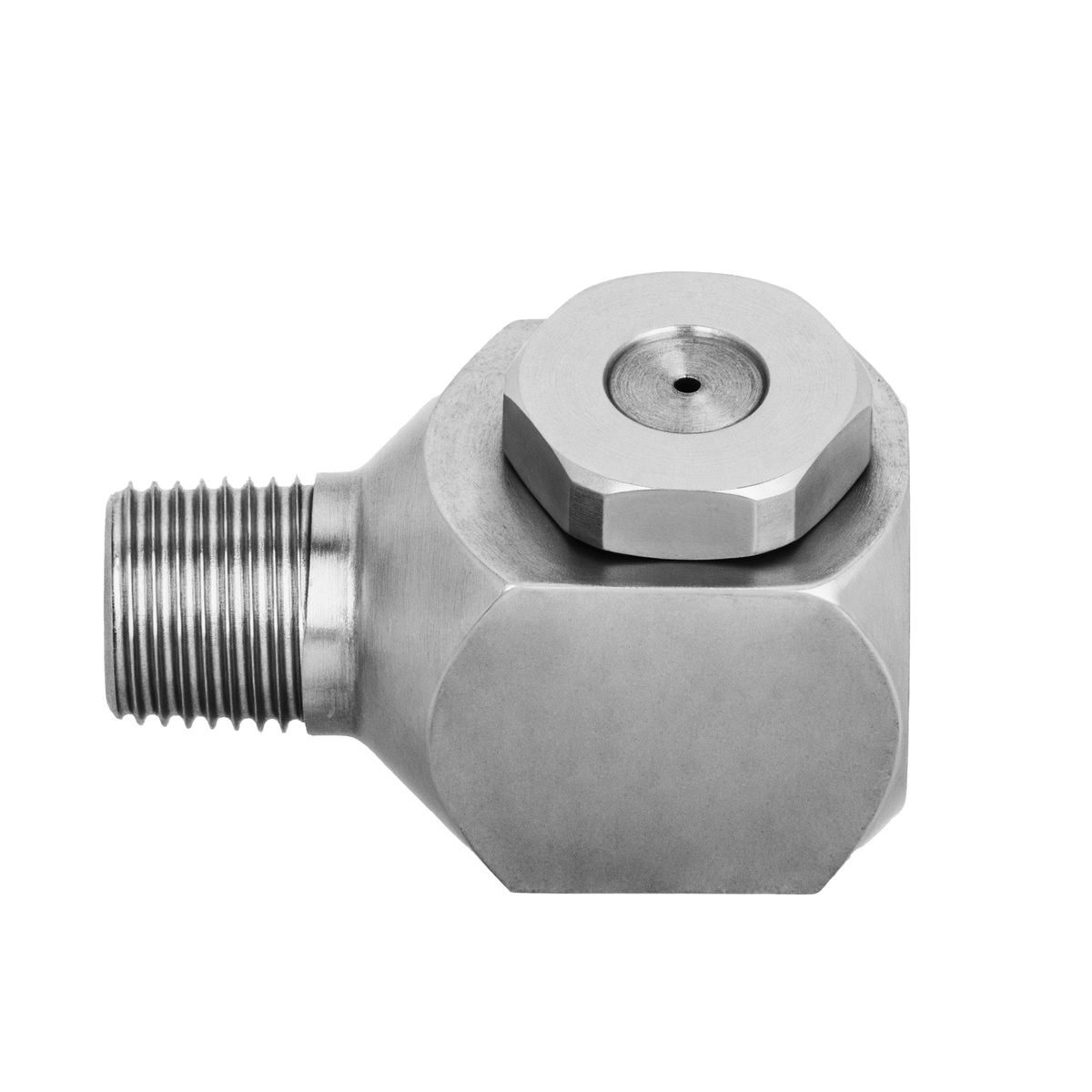

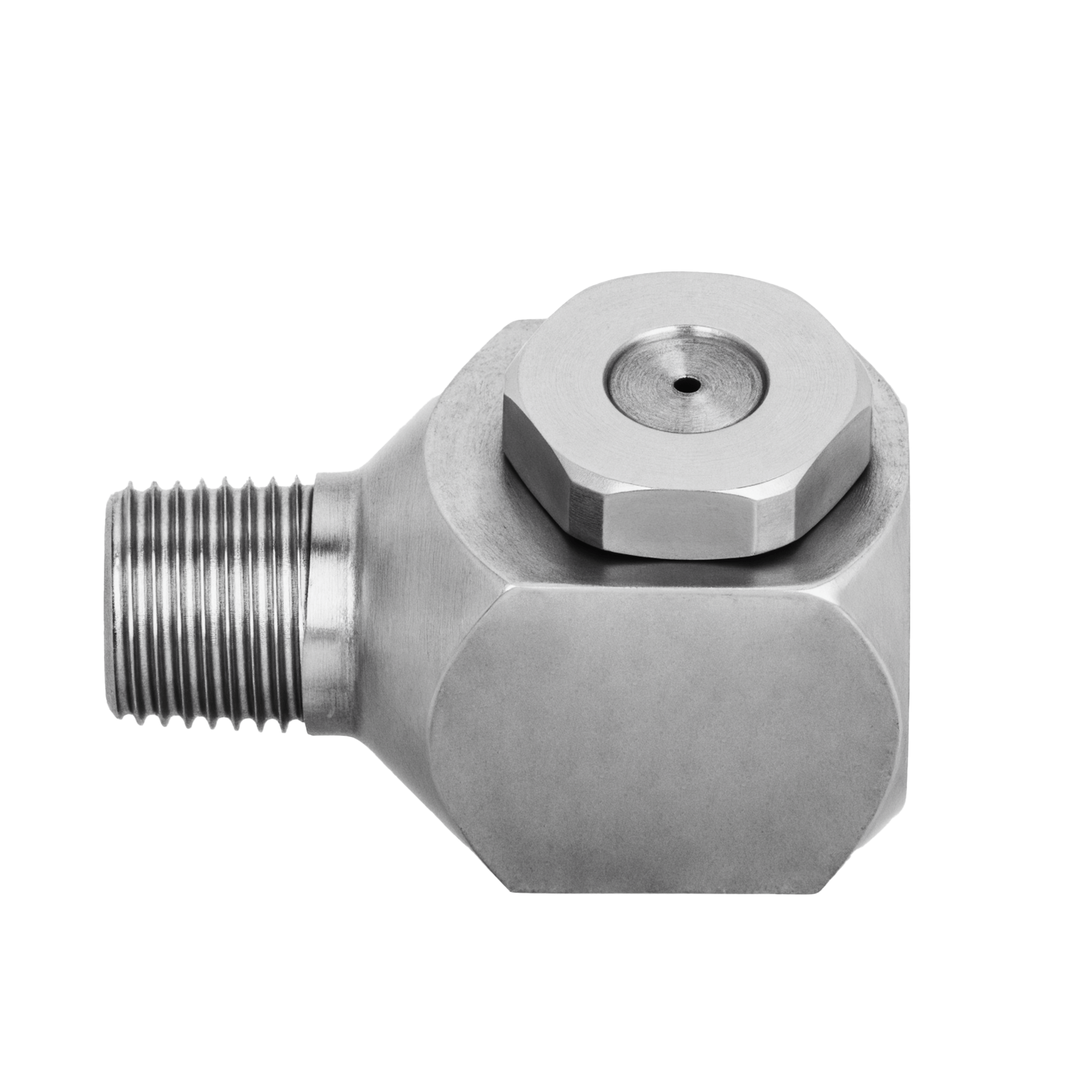

| Product Series | NPBX |

| Capacity Size | 1-10W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 1.6 |

| Orifice Diameter. Nom. (in) | 0.172 |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 35 |

| Length (in) | 1.375 |

| Inlet Dia. Nom. (in) | 0.063 |

| Max. Free Passage Dia. (mm) | 4.4 |

Description

Product Overview

When automotive crews manage cooling & quenching, the NPBX-1-10W-1/4-316 lets each maintenance supervisor deploy a corrosion-resistant 316L stainless steel nozzle that delivers a consistent hollow cone spray pattern. Operators install the nozzle using its 1/4-inch inlet, ensuring a tight fit within existing fluid delivery systems. The uniform spray distribution contributes to controlled temperature reduction and extended equipment life by minimizing heat stress on components. The NPBX-1-10W-1/4-316 is engineered for durability in harsh environments where precise fluid application is critical.

Applications

In processes requiring cooling & quenching, the nozzle maintains stable temperature profiles that improve material properties and reduce cycle times. Additionally, its role in dust & pollution control supports cleaner work environments by effectively suppressing airborne particulates during industrial operations.

Industries

Sectors such as automotive, chemical processing, and steel & metals rely on the NPBX-1-10W-1/4-316 because its corrosion resistance and reliable spray pattern meet the demands of harsh industrial conditions. Breweries & wineries, building materials, and manufacturing & assembly facilities also use this nozzle to enhance process consistency and equipment longevity.