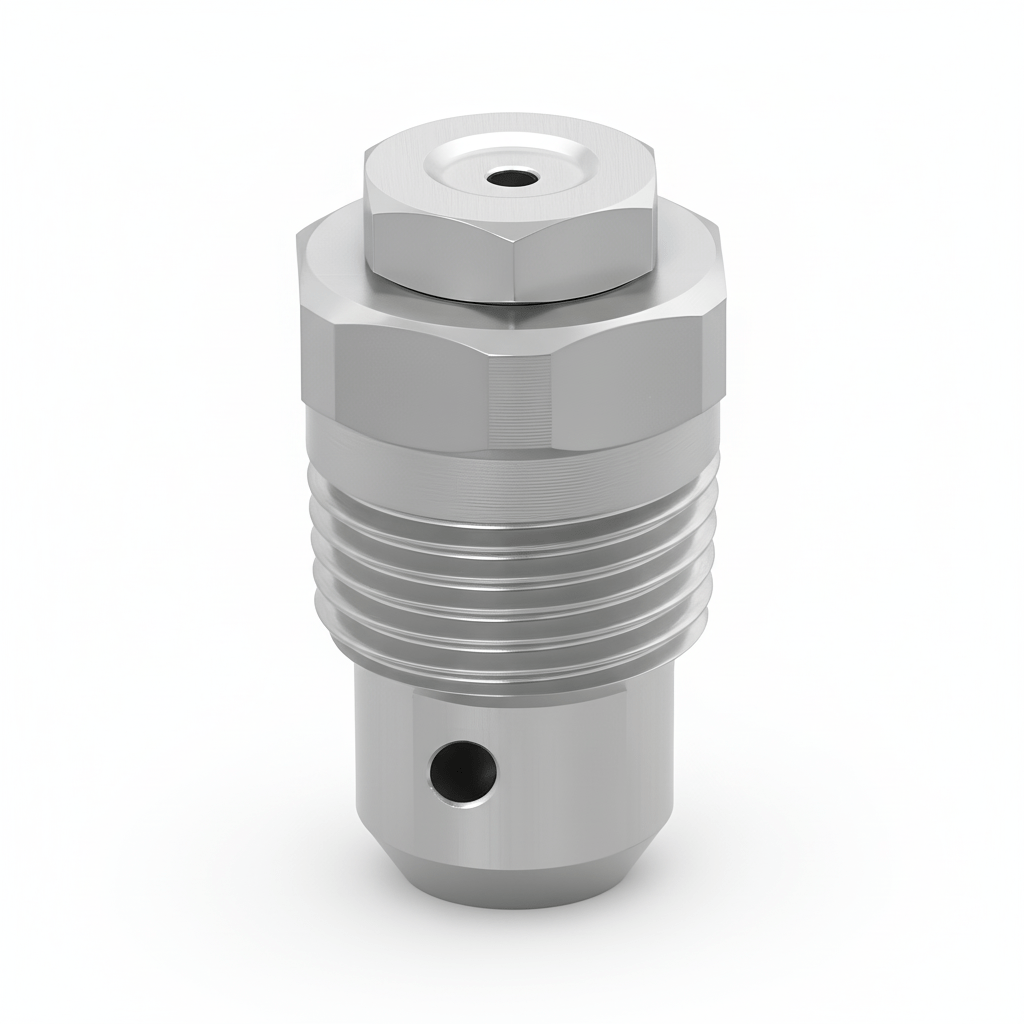

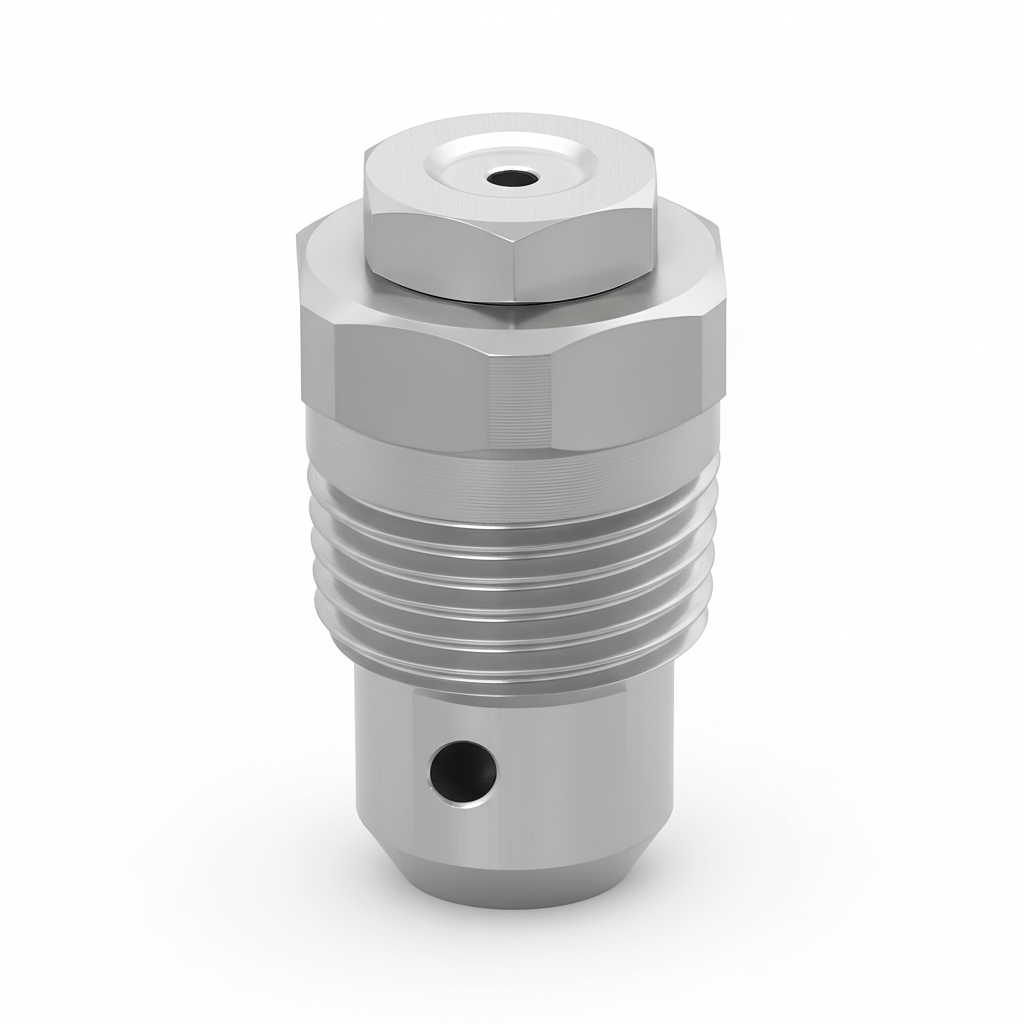

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBD |

| Capacity Size | 80 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 14.3 |

| Orifice Diameter. Nom. (in) | 0.563 |

| Inlet Connection Size (in.) | 1-1/2 |

| Hex Size (mm) | 50.8 |

| Inlet Dia. Nom. (mm) | 9.5+ |

| Inlet Dia. Nom. (in) | 0.375* |

Description

Product Overview

A utilities coordinator in the cement facility uses the NPBD-80-1-1/2-316 during specialty applications to deliver a consistent hollow cone spray pattern essential for even material coverage. Constructed from 316L stainless steel, this nozzle withstands corrosive environments common in the plant's processes. Its 1-1/2 inch inlet size facilitates integration with existing piping systems while maintaining uniform fluid distribution. The operator observes improved spray reliability and reduced maintenance intervals due to the nozzle's material durability and precision design.

Applications

In cooling & quenching operations, the NPBD-80-1-1/2-316 supports efficient temperature control by providing a stable spray that enhances heat dissipation. Additionally, its role in dust & pollution control helps minimize airborne particulates, contributing to cleaner plant atmospheres and compliance with environmental standards.

Industries

Sectors such as building materials, mining, and cement utilize this nozzle for its corrosion resistance and uniform spray capabilities, which are critical in harsh processing environments. The manufacturing & assembly and roofing industries also benefit from the NPBD-80-1-1/2-316's reliable performance in fluid handling tasks that demand consistent spray patterns and material compatibility.