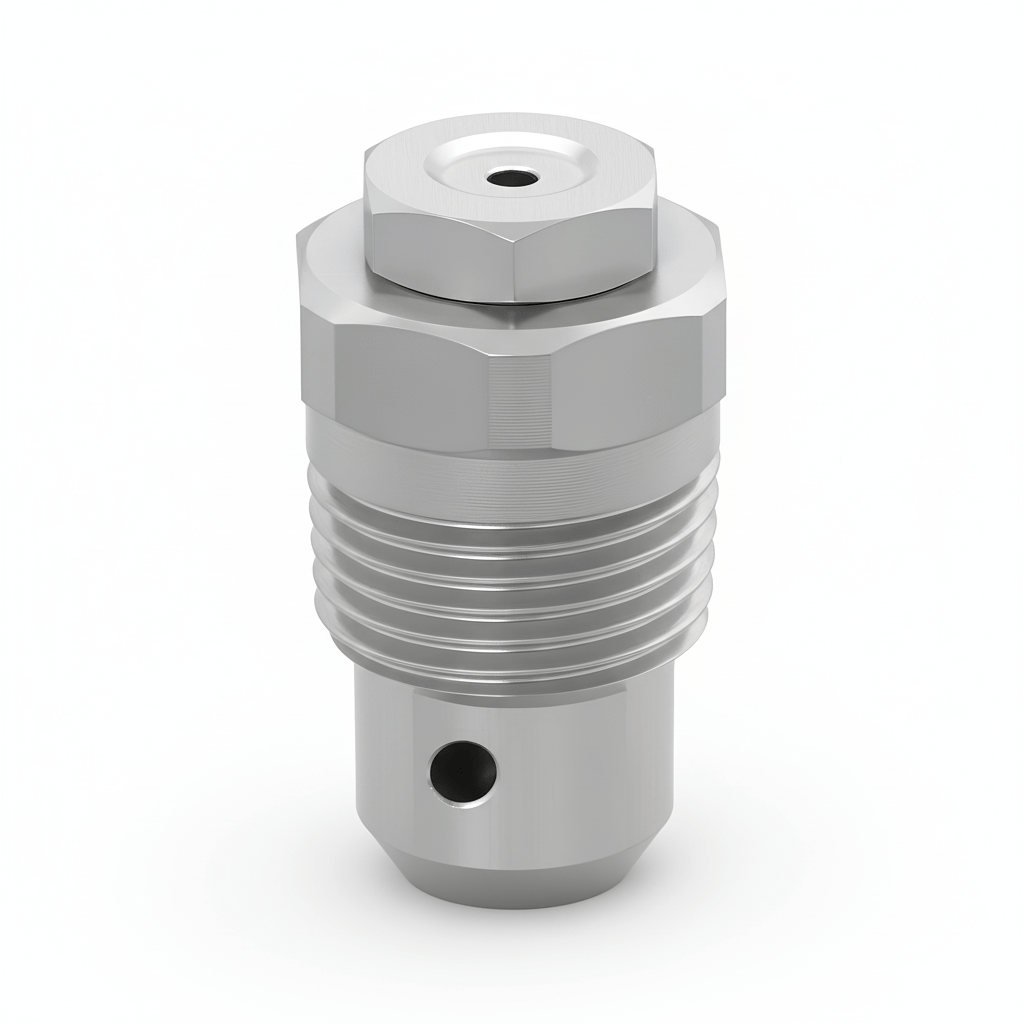

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBD |

| Capacity Size | 60 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 11.1 |

| Orifice Diameter. Nom. (in) | 0.438 |

| Inlet Connection Size (in.) | 1-1/2 |

| Hex Size (mm) | 50.8 |

| Inlet Dia. Nom. (mm) | 9.5+ |

| Inlet Dia. Nom. (in) | 0.375* |

Description

Product Overview

A production technician in the cement facility uses the NPBD-60-1-1/2-316 during cooling & quenching to achieve consistent temperature control on heated components. The nozzle's 316L stainless steel construction ensures resistance to corrosion from abrasive dust and moisture exposure. Its precision hollow cone spray delivers uniform coverage, which helps maintain equipment integrity and process stability. The 1-1/2 inlet size facilitates integration with existing piping systems, supporting efficient fluid distribution.

Applications

In cooling & quenching processes, the nozzle provides even spray distribution that helps prevent thermal damage and material distortion. Dust & pollution control applications benefit from its uniform spray pattern, enabling effective particulate suppression and improved air quality around the operation area.

Industries

Sectors such as building materials, mining, and cement rely on the NPBD-60-1-1/2-316 for its durability and consistent spray performance under harsh conditions. The nozzle's compatibility with manufacturing & assembly and roofing operations further demonstrates its adaptability to diverse industrial requirements.