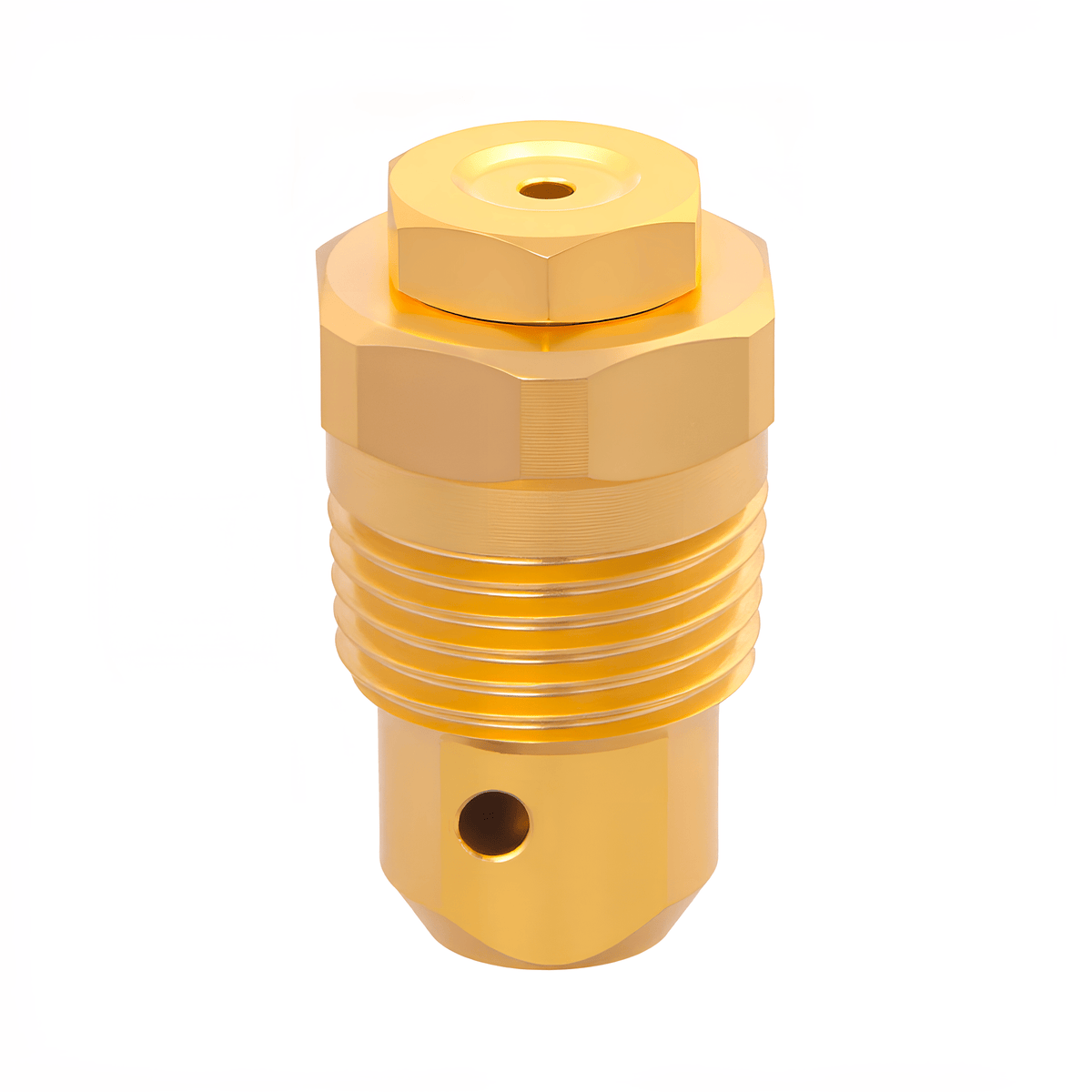

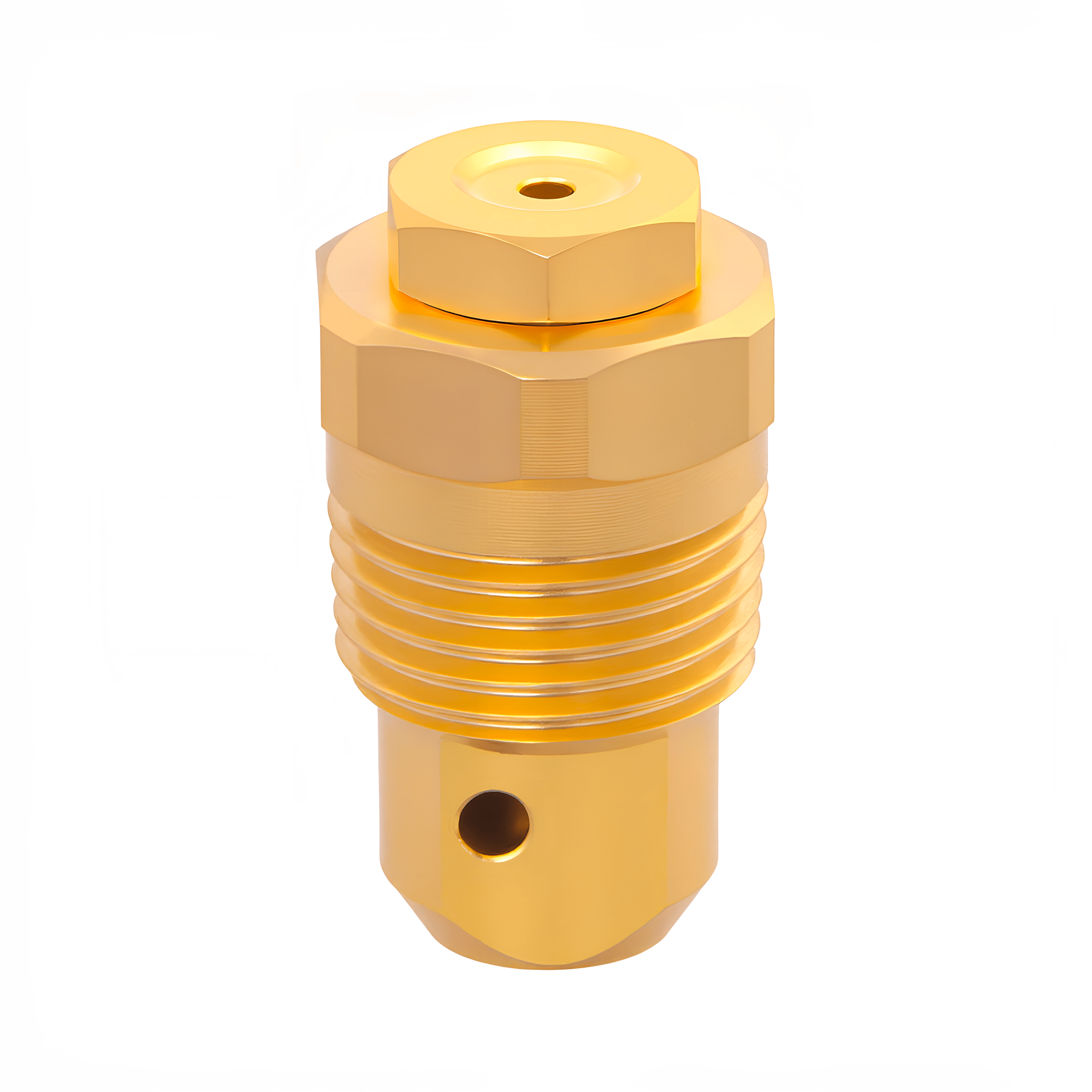

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBD |

| Capacity Size | 40 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 7.9 |

| Orifice Diameter. Nom. (in) | 0.313 |

| Inlet Connection Size (in.) | 1-1/2 |

| Hex Size (mm) | 50.8 |

| Inlet Dia. Nom. (mm) | 9.5+ |

| Inlet Dia. Nom. (in) | 0.375* |

Description

Product Overview

When building materials crews manage cooling & quenching, the NPBD-40-1-1/2 lets each production technician achieve consistent spray coverage with its precision hollow cone design. Constructed of brass, the nozzle resists corrosion from harsh process fluids, maintaining performance over prolonged use. Operators typically connect the 1-1/2 inch inlet to standard piping, adjusting flow rates to optimize temperature control and minimize thermal stress during material handling. This controlled spray pattern supports stable process conditions while reducing downtime for maintenance.

Applications

In cooling & quenching operations, the NPBD-40-1-1/2 delivers uniform fluid distribution essential for maintaining material integrity and equipment longevity. Additionally, its role in dust & pollution control helps contain airborne particulates, improving environmental compliance and worker safety.

Industries

Sectors such as building materials, mining, cement, and manufacturing & assembly rely on this nozzle for its durability and consistent spray performance under demanding conditions. Roofing contractors and facilities within the Energy industry also utilize the NPBD-40-1-1/2 to ensure reliable fluid delivery where process precision and corrosion resistance are critical.