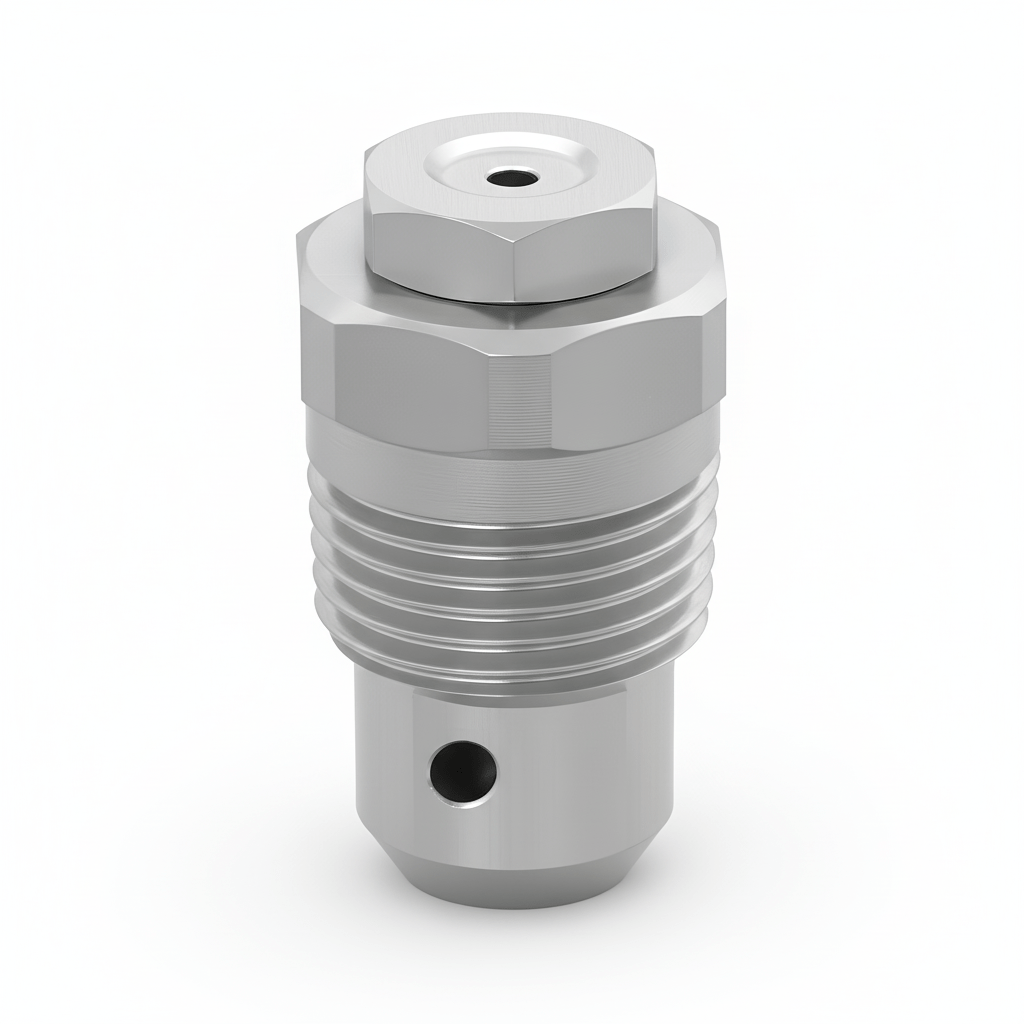

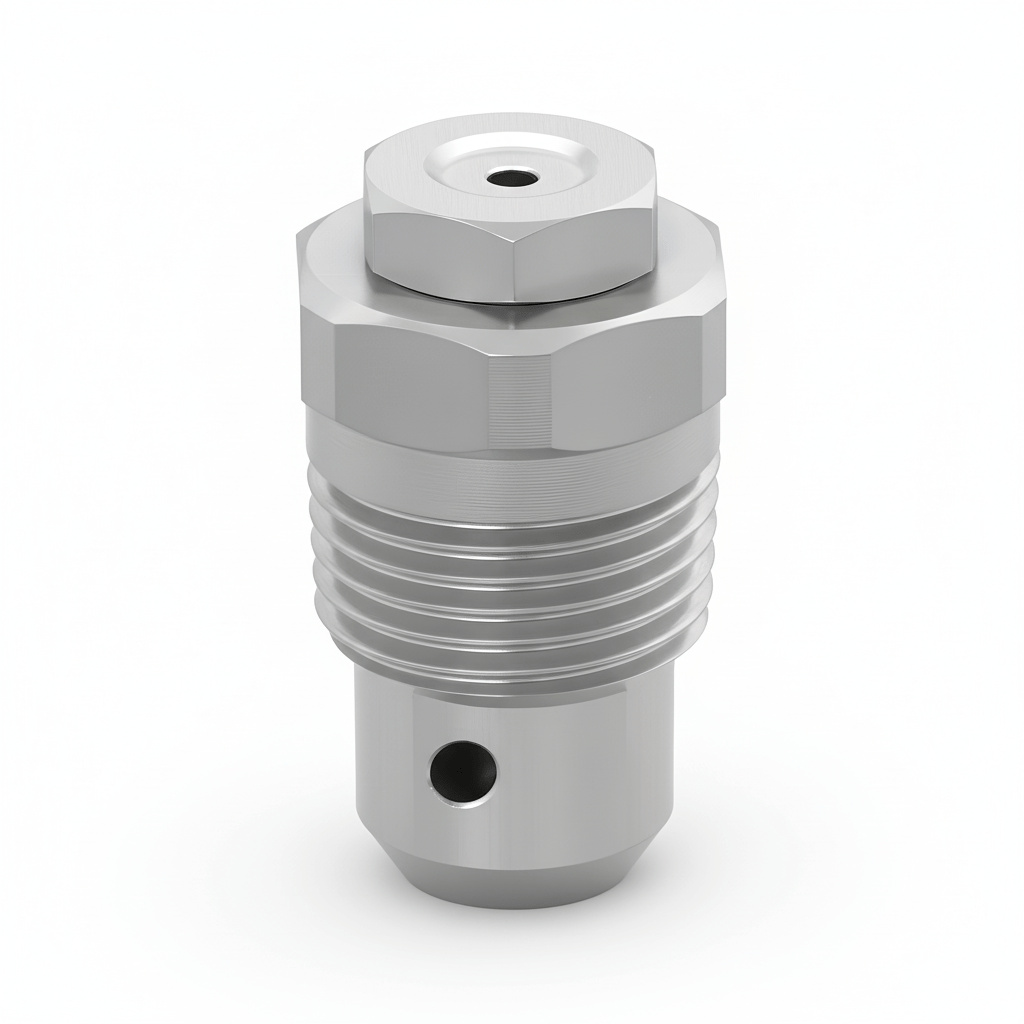

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBD |

| Capacity Size | 2 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 2 |

| Orifice Diameter. Nom. (in) | 0.078 |

| Inlet Connection Size (in.) | 3/8 |

| Hex Size (mm) | 17.5 |

| Inlet Dia. Nom. (mm) | 2.4 |

| Inlet Dia. Nom. (in) | 0.094 |

Description

Product Overview

Inside the roofing line's cooling & quenching stage, a utilities coordinator relies on the NPBD-2-3/8-316 to deliver consistent spray coverage essential for regulating surface temperatures. Constructed from 316l stainless steel, this hollow cone nozzle features a 3/8 inch inlet that withstands corrosion in harsh environments. The uniform spray pattern ensures even distribution of coolant, reducing thermal stress on roofing materials and extending equipment service intervals. Operators monitor flow rates and spray angles to maintain process stability and optimize cooling efficiency.

Applications

In the cooling & quenching process, the nozzle's precise atomization minimizes water usage while achieving rapid temperature reduction, which is critical to maintaining product integrity. Additionally, its role in dust & pollution control helps capture airborne particulates, improving workplace safety and reducing environmental emissions in adjacent production areas.

Industries

Sectors such as building materials, mining, and cement production favor the NPBD-2-3/8-316 for its resistance to abrasive and corrosive substances commonly encountered in their processes. Energy and manufacturing & assembly operations benefit from the nozzle's durability and consistent spray performance, which contribute to reliable system operation and reduced maintenance requirements.