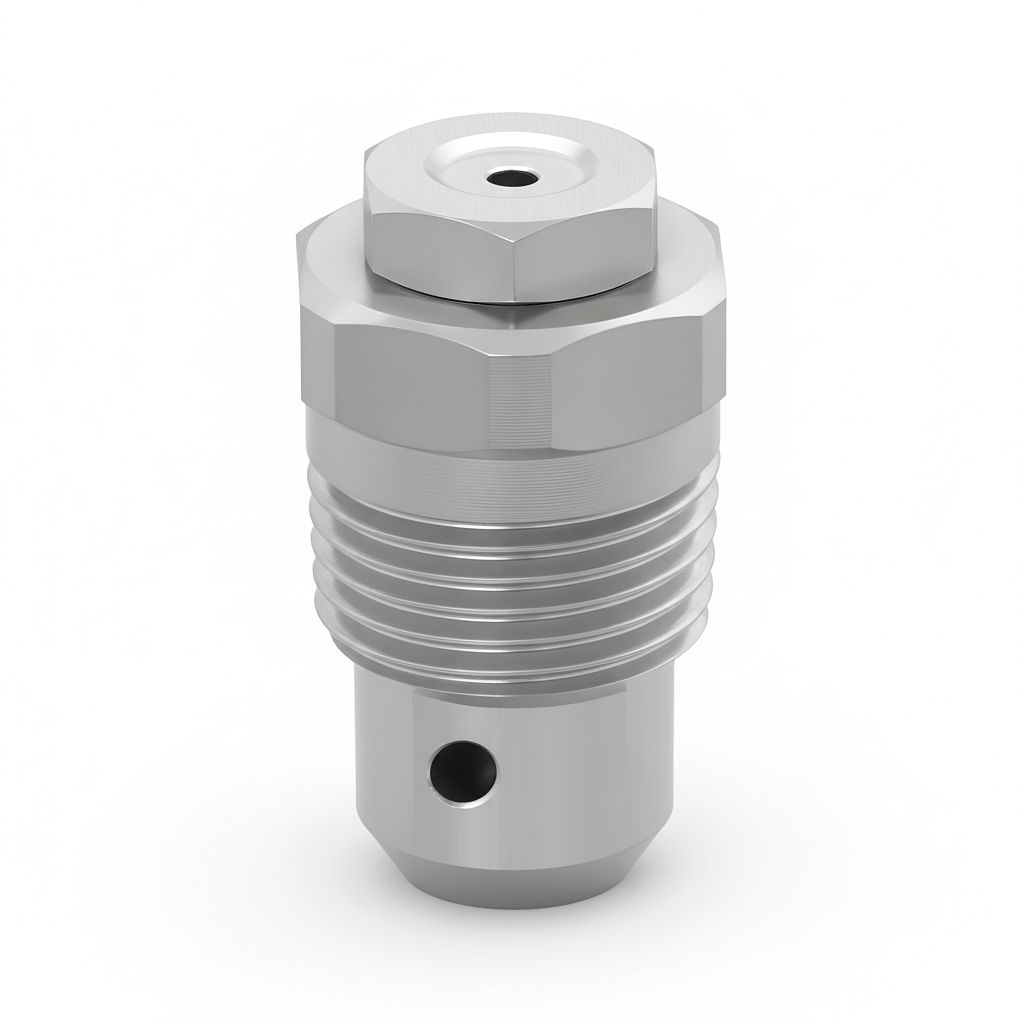

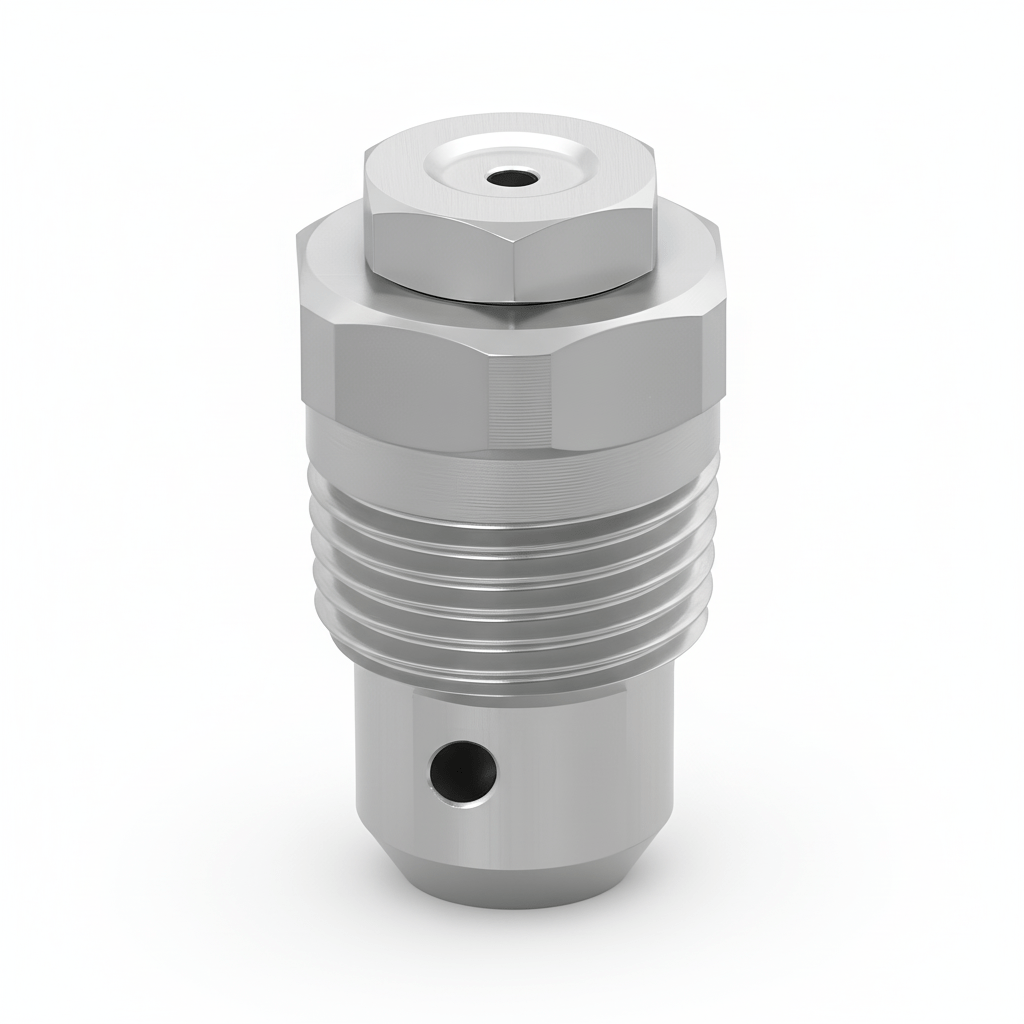

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBD |

| Capacity Size | 15 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 5.6 |

| Orifice Diameter. Nom. (in) | 0.219 |

| Inlet Connection Size (in.) | 3/4 |

| Hex Size (mm) | 27 |

| Inlet Dia. Nom. (mm) | 6.4 |

| Inlet Dia. Nom. (in) | 0.25 |

Description

Product Overview

A plant operator in the cement facility uses the NPBD-15-3/4-316 during specialty applications to achieve consistent surface coverage and controlled droplet size. Constructed from 316L stainless steel, this nozzle withstands corrosive environments typical of cement processing. The hollow cone spray pattern ensures uniform distribution, which enhances material conditioning and reduces downtime due to maintenance. Its 3/4-inch inlet simplifies integration into existing piping systems while delivering reliable flow rates for process stability.

Applications

In cooling & quenching, the nozzle enables effective temperature control by delivering an even spray that accelerates heat dissipation without material degradation. Additionally, dust & pollution control operations benefit from this nozzle's ability to generate fine mist coverage, which suppresses airborne particles and improves air quality around the plant.

Industries

Sectors such as building materials, mining, and Energy favor the NPBD-15-3/4-316 for its durability and resistance to abrasive or corrosive substances encountered in harsh process conditions. Manufacturing & assembly and roofing industries also utilize this nozzle to maintain precise fluid delivery, ensuring consistent product quality and operational efficiency.