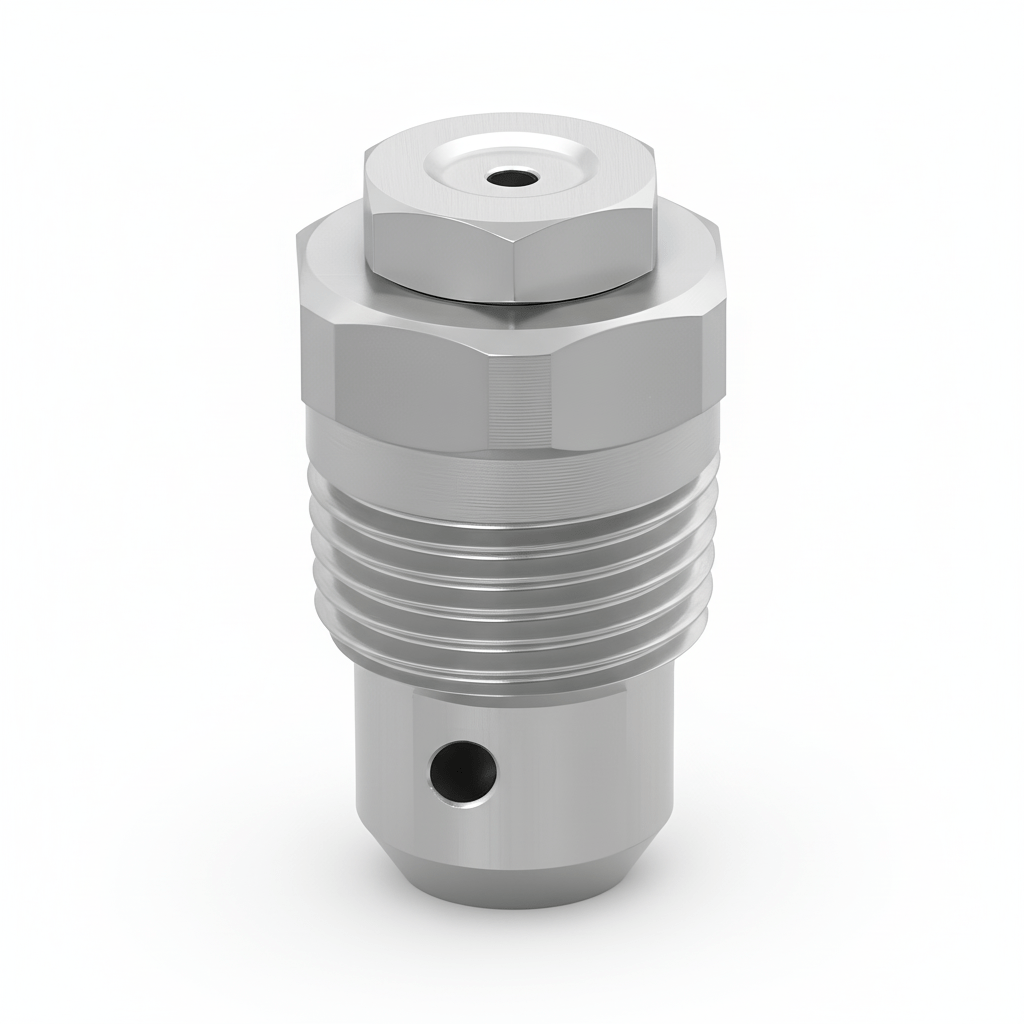

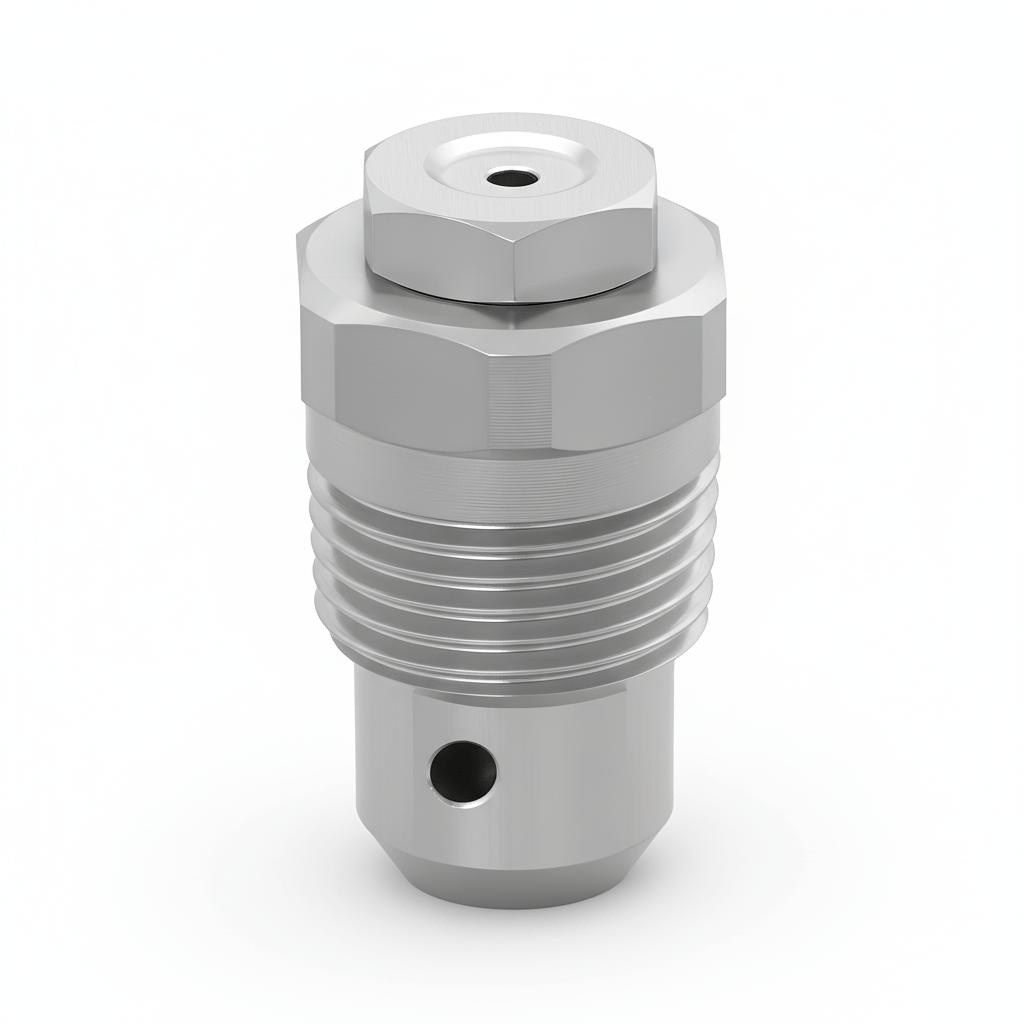

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBD |

| Capacity Size | 10 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 4.4 |

| Orifice Diameter. Nom. (in) | 0.172 |

| Inlet Connection Size (in.) | 3/8 |

| Hex Size (mm) | 17.5 |

| Inlet Dia. Nom. (mm) | 4 |

| Inlet Dia. Nom. (in) | 0.156 |

Description

Product Overview

During cooling & quenching on a manufacturing & assembly site, plant operators trust the NPBD-10-3/8-316 to deliver consistent and controlled spray coverage. Constructed from 316L stainless steel, this nozzle withstands corrosive environments while maintaining structural integrity. Its precision hollow cone design ensures a uniform distribution of fluid over the target surface, optimizing process efficiency and reducing thermal stress. By integrating the NPBD-10-3/8-316, operators achieve reliable cooling rates essential for maintaining product quality.

Applications

In cooling & quenching operations, the uniform spray pattern of the NPBD-10-3/8-316 contributes to precise temperature control, which is critical for material properties and downstream machining processes. The nozzle's corrosion resistance also supports dust & pollution control efforts by enabling consistent atomization in harsh environments, minimizing particulate release.

Industries

Sectors such as building materials, mining, and cement leverage this nozzle for its durability and spray consistency under demanding conditions. Additionally, roofing and Energy industries depend on its corrosion-resistant features to sustain long-term performance in fluid handling applications.