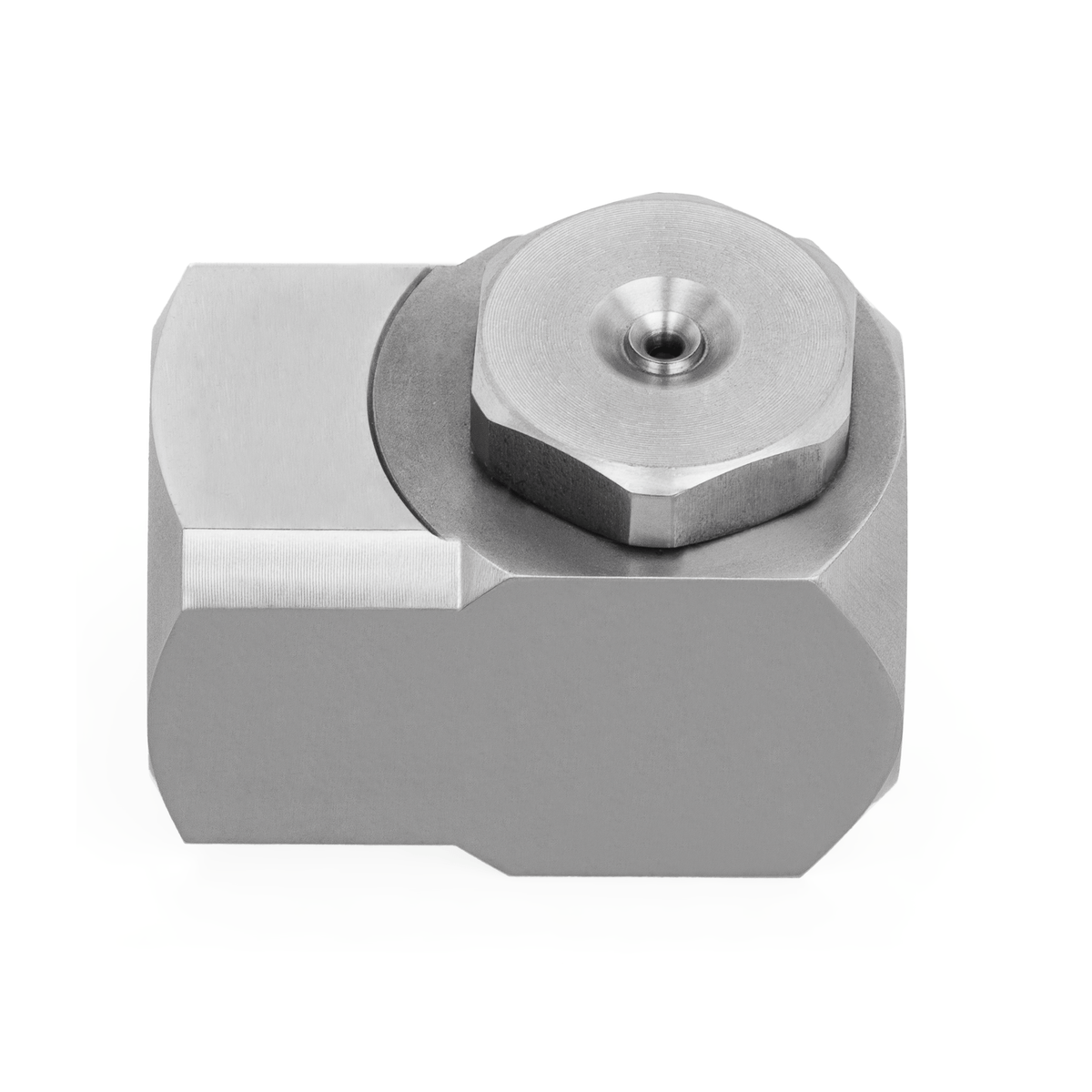

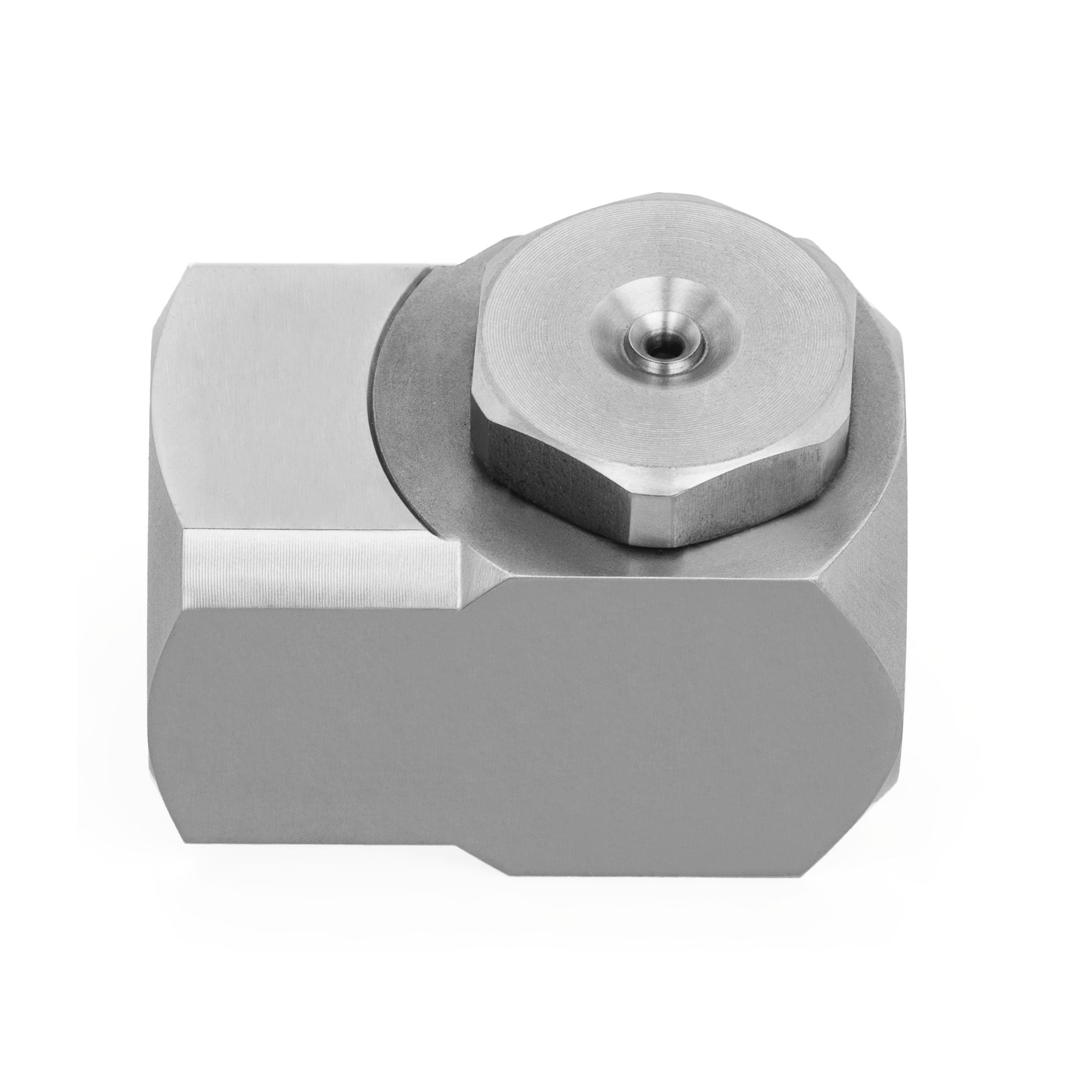

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPAX |

| Capacity Size | 8-15W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | FEMALE (F) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 4 |

| Orifice Diameter. Nom. (in) | 0.219 |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 32 |

| Length (in) | 1.250 |

| Inlet Dia. Nom. (in) | 0.156 |

| Max. Free Passage Dia. (mm) | 5.6 |

Description

Product Overview

Inside the breweries & wineries line's humidification & conditioning stage, a process engineer relies on the NPAX-8-15W-1/4-316 to deliver consistent spray distribution critical for maintaining optimal environmental conditions. Constructed from 316L stainless steel, the nozzle resists corrosion and withstands the humid atmosphere typical of this application. Its precision hollow cone design ensures a uniform spray pattern, which contributes to stable humidity levels and improved air quality. By integrating this nozzle, operators achieve reliable performance that supports both product quality and equipment longevity.

Applications

In humidification & conditioning operations, the NPAX-8-15W-1/4-316 facilitates controlled moisture delivery that prevents process disruptions caused by dry air. Additionally, it plays a role in dust & pollution control by producing fine droplets that help capture airborne particulates, thereby reducing contamination risks downstream.

Industries

The NPAX-8-15W-1/4-316 is favored in automotive, chemical processing, and steel & metals industries due to its durability in corrosive environments and ability to maintain consistent spray characteristics. Manufacturing & assembly plants and meat & poultry facilities also benefit from its precise flow control, which supports critical stages such as cooling & quenching and specialty applications.