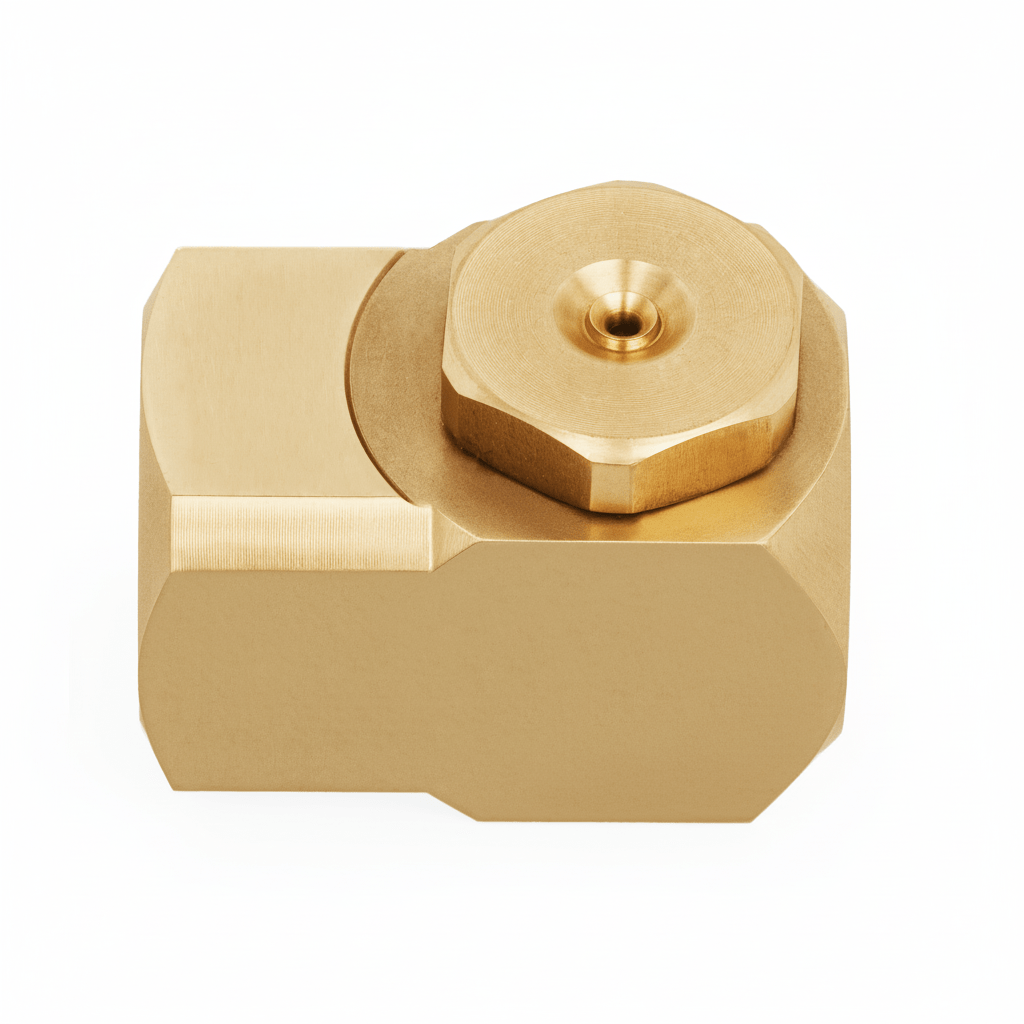

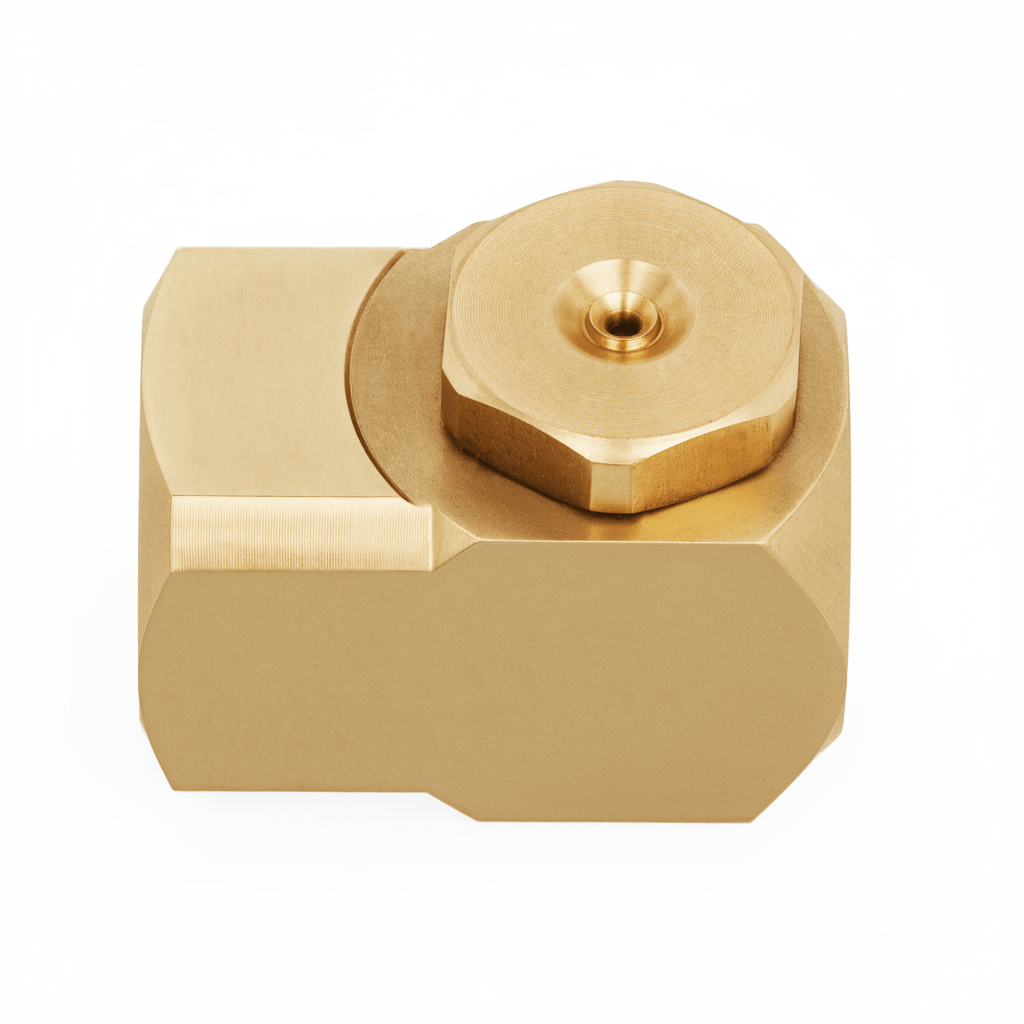

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPAX |

| Capacity Size | 3-3W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | FEMALE (F) |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 2.4 |

| Orifice Diameter. Nom. (in) | 0.109 |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 25.5 |

| Length (in) | 1.000 |

| Inlet Dia. Nom. (in) | 0.094 |

| Max. Free Passage Dia. (mm) | 2.8 |

Description

Product Overview

Inside the building materials line's humidification & conditioning stage, a production technician relies on the NPAX-3-3W-1/8 to deliver consistent moisture levels critical for product quality. The technician installs the brass hollow cone nozzle with its 1/8-inch inlet to ensure uniform spray distribution across the drying chamber. Its corrosion-resistant construction supports long operational cycles in harsh environments, minimizing downtime. By maintaining precise spray coverage, the operator helps achieve stable humidity control, which directly influences material curing and surface finish.

Applications

In cooling & quenching processes, the NPAX-3-3W-1/8 provides a uniform hollow cone spray that rapidly dissipates heat from metal components, reducing cycle times and improving metallurgical properties. Additionally, its use in dust & pollution control helps capture airborne particulates efficiently, contributing to cleaner work environments and improved regulatory compliance.

Industries

This nozzle is widely used in automotive and steel & metals manufacturing due to its durability and consistent spray characteristics, which are essential for cooling and surface treatment operations. The chemical processing and breweries & wineries sectors also benefit from its corrosion resistance and precise flow control, while manufacturing & assembly and meat & poultry industries value its role in maintaining environmental conditions and product quality.