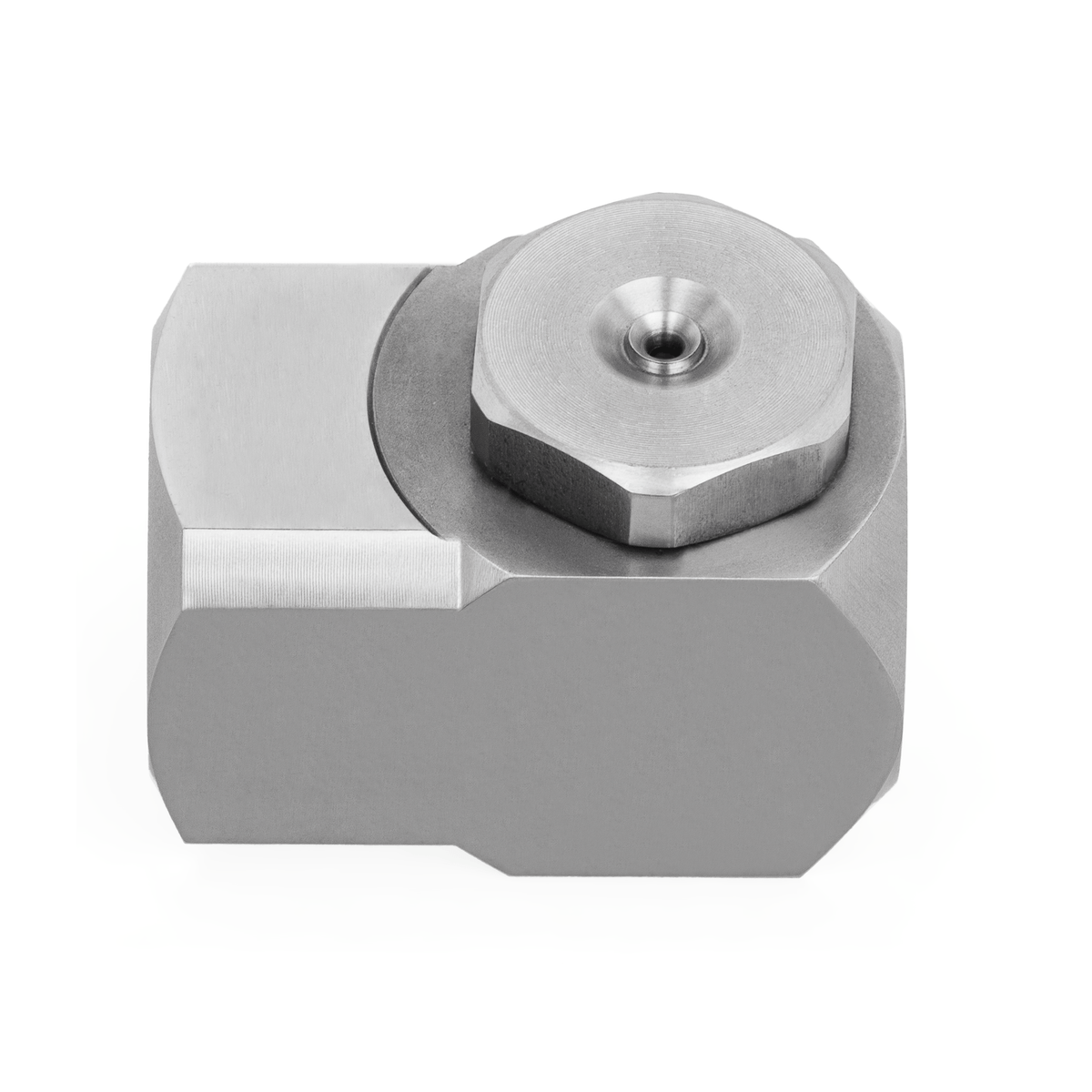

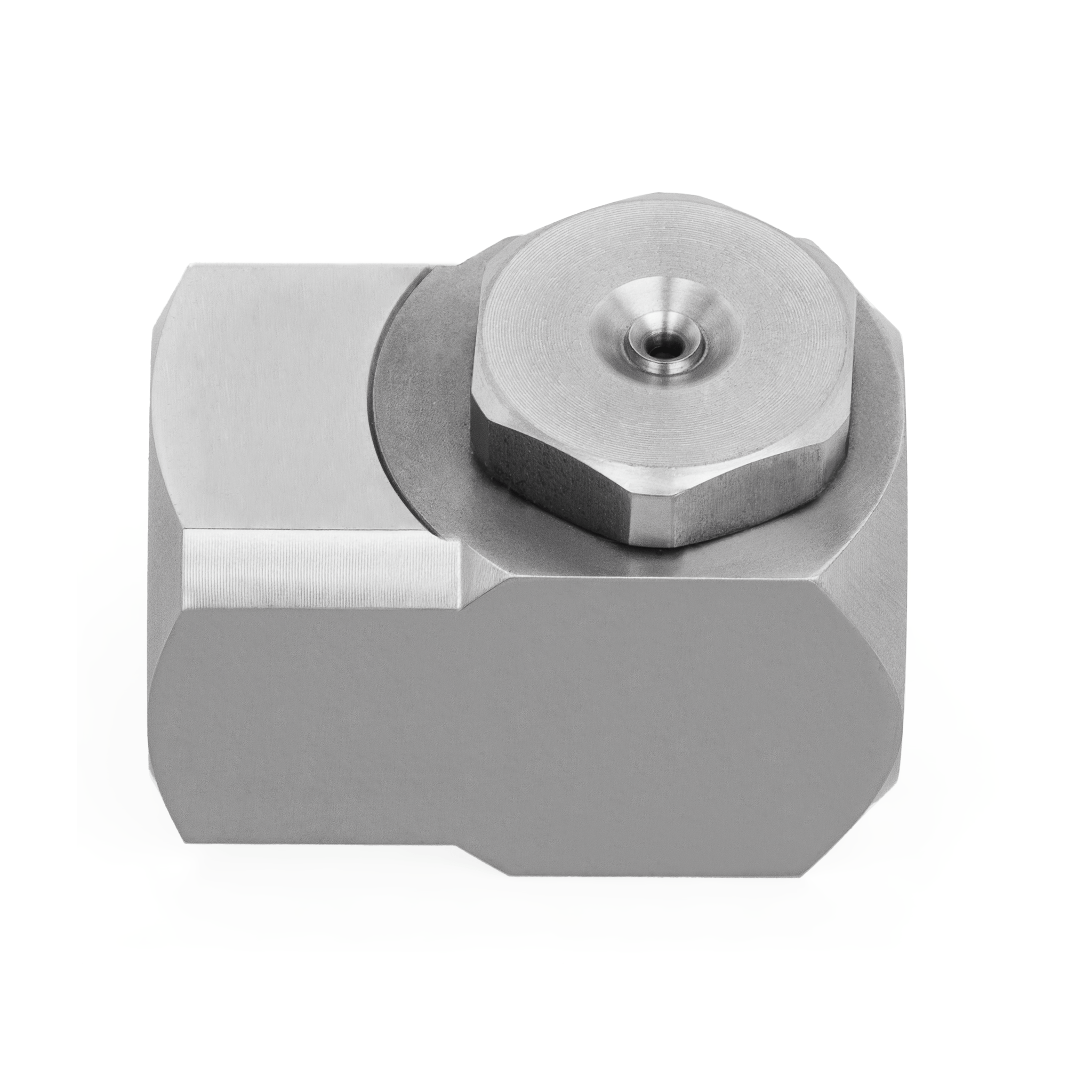

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPAX |

| Capacity Size | 2-5W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | FEMALE (F) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 2 |

| Orifice Diameter. Nom. (in) | 0.125 |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 32 |

| Length (in) | 1.250 |

| Inlet Dia. Nom. (in) | 0.078 |

| Max. Free Passage Dia. (mm) | 3.2 |

Description

Product Overview

When building materials crews manage cooling & quenching, the NPAX-2-5W-1/4-316 lets each maintenance supervisor install a reliable nozzle constructed from 316L stainless steel to withstand corrosive environments. Operators connect the 1/4-inch inlet to existing piping systems, ensuring consistent hollow cone spray distribution essential for uniform surface cooling. The stainless steel body not only provides durability but also maintains precise spray angles that help optimize process efficiency while reducing maintenance frequency. This nozzle's design supports stable and repeatable operation across diverse industrial conditions.

Applications

In cooling & quenching processes, the NPAX-2-5W-1/4-316 delivers uniform spray coverage critical for preventing thermal stress and improving product quality. Additionally, its use in dust & pollution control helps capture particulates effectively, contributing to cleaner work environments and compliance with environmental regulations.

Industries

The nozzle's corrosion resistance and consistent spray pattern meet the operational demands of industries such as automotive, chemical processing, steel & metals, and breweries & wineries. Manufacturing & assembly facilities, as well as those involved in meat & poultry, rely on this nozzle to maintain process stability and extend equipment service life under challenging conditions.