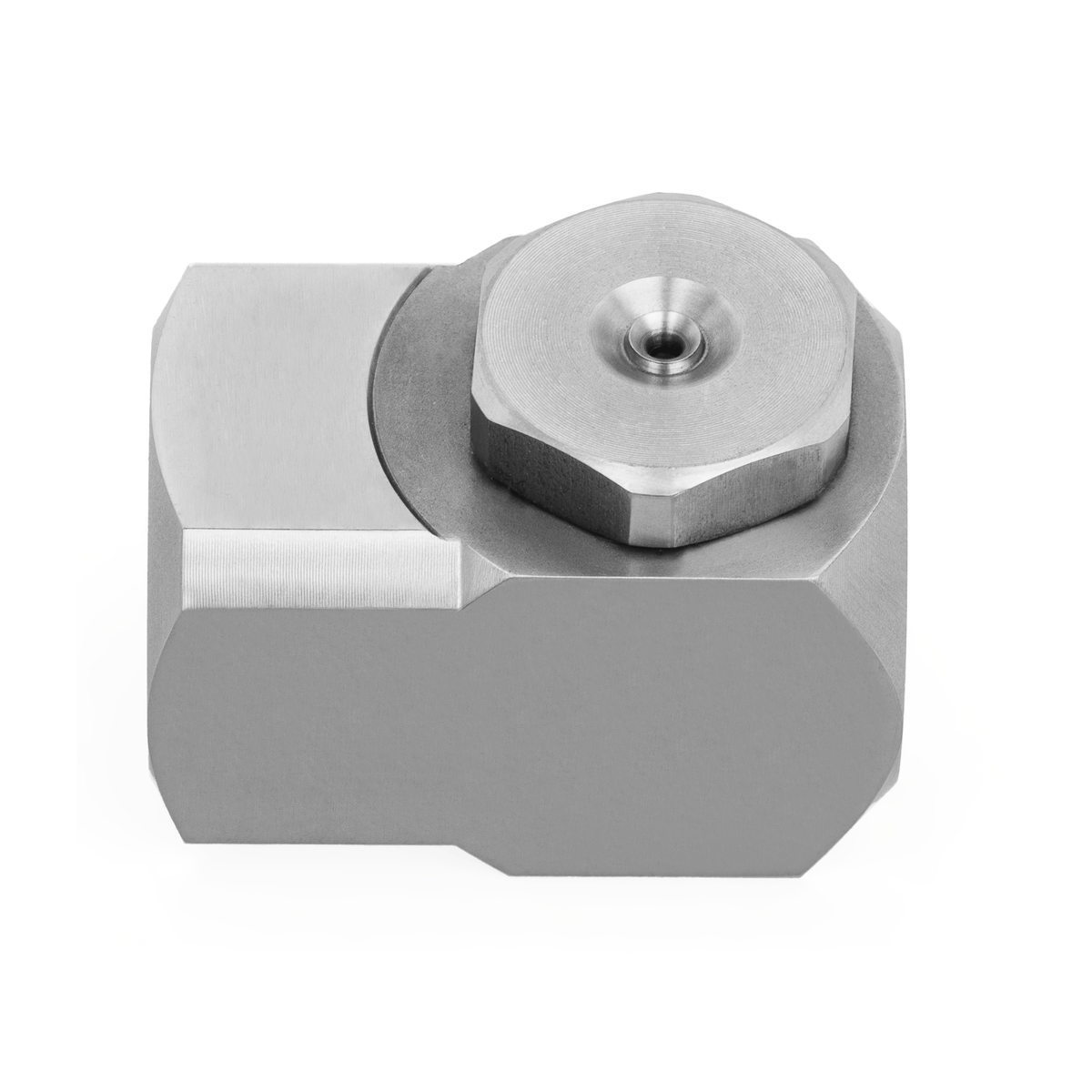

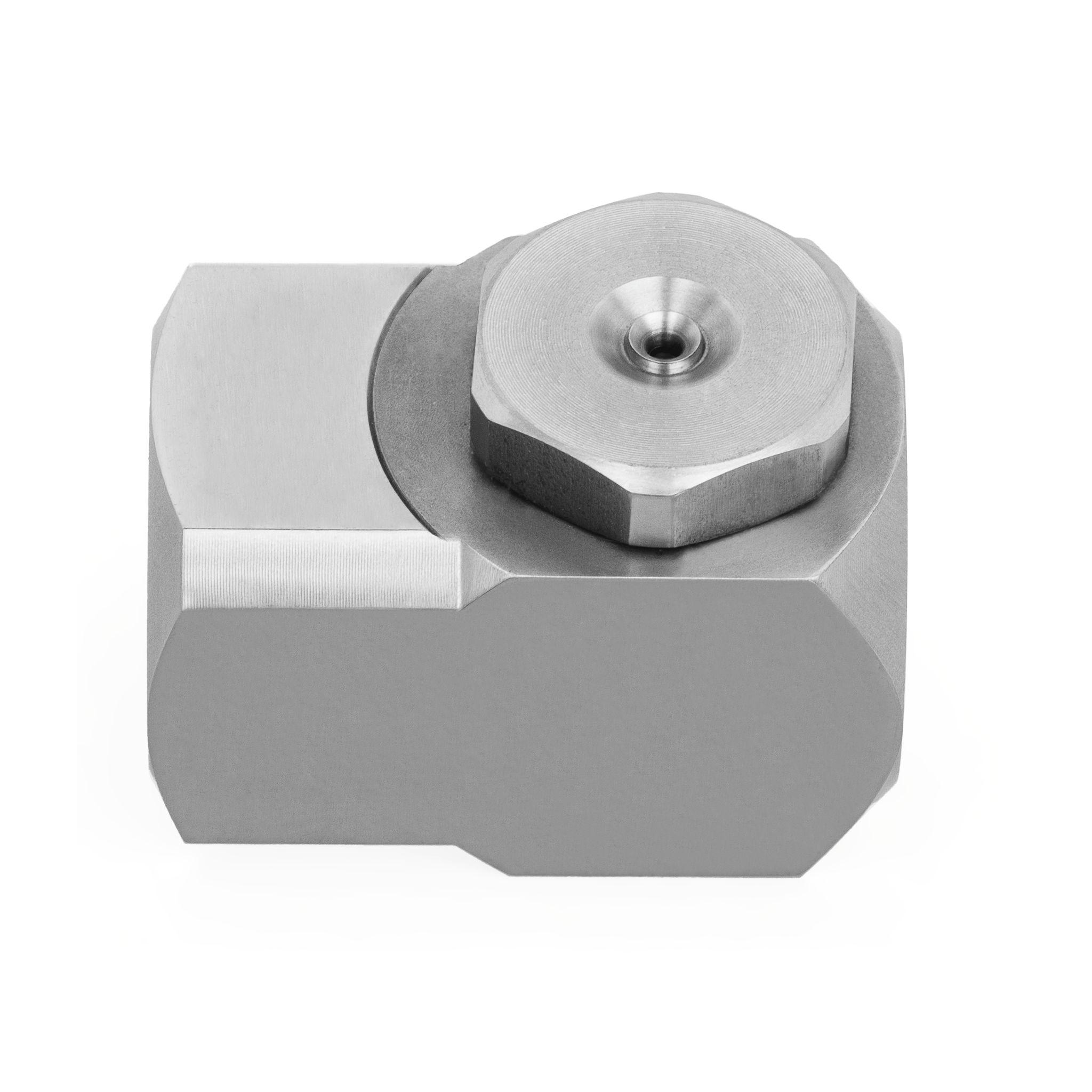

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPAX |

| Capacity Size | 15-30W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | FEMALE (F) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 6 |

| Orifice Diameter. Nom. (in) | 0.313 |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 37.5 |

| Length (in) | 1.469 |

| Inlet Dia. Nom. (in) | 0.234 |

| Max. Free Passage Dia. (mm) | 7.9 |

Description

Product Overview

When chemical processing crews manage specialty applications, the NPAX-15-30W-3/8-316 lets each process engineer achieve consistent coverage through its precision hollow cone spray pattern. Made from 316L stainless steel, this nozzle withstands corrosive environments while delivering uniform distribution critical for process stability. Operators install the nozzle using the 3/8-inch inlet, ensuring compatibility with standard piping systems. The reliable spray characteristics support controlled material transfer and efficient resource use within demanding operational settings.

Applications

This nozzle supports cooling & quenching operations by providing an even spray that helps maintain target temperatures and material integrity. In dust & pollution control scenarios, the hollow cone pattern improves particulate capture, reducing environmental emissions and enhancing workplace safety.

Industries

Automotive, building materials, and chemical processing sectors rely on the NPAX-15-30W-3/8-316 for its corrosion resistance and spray consistency under varied operating conditions. Energy, steel & metals, breweries & wineries, as well as manufacturing & assembly and meat & poultry industries use this nozzle to meet their diverse process demands, particularly where material handling and environmental control are critical.