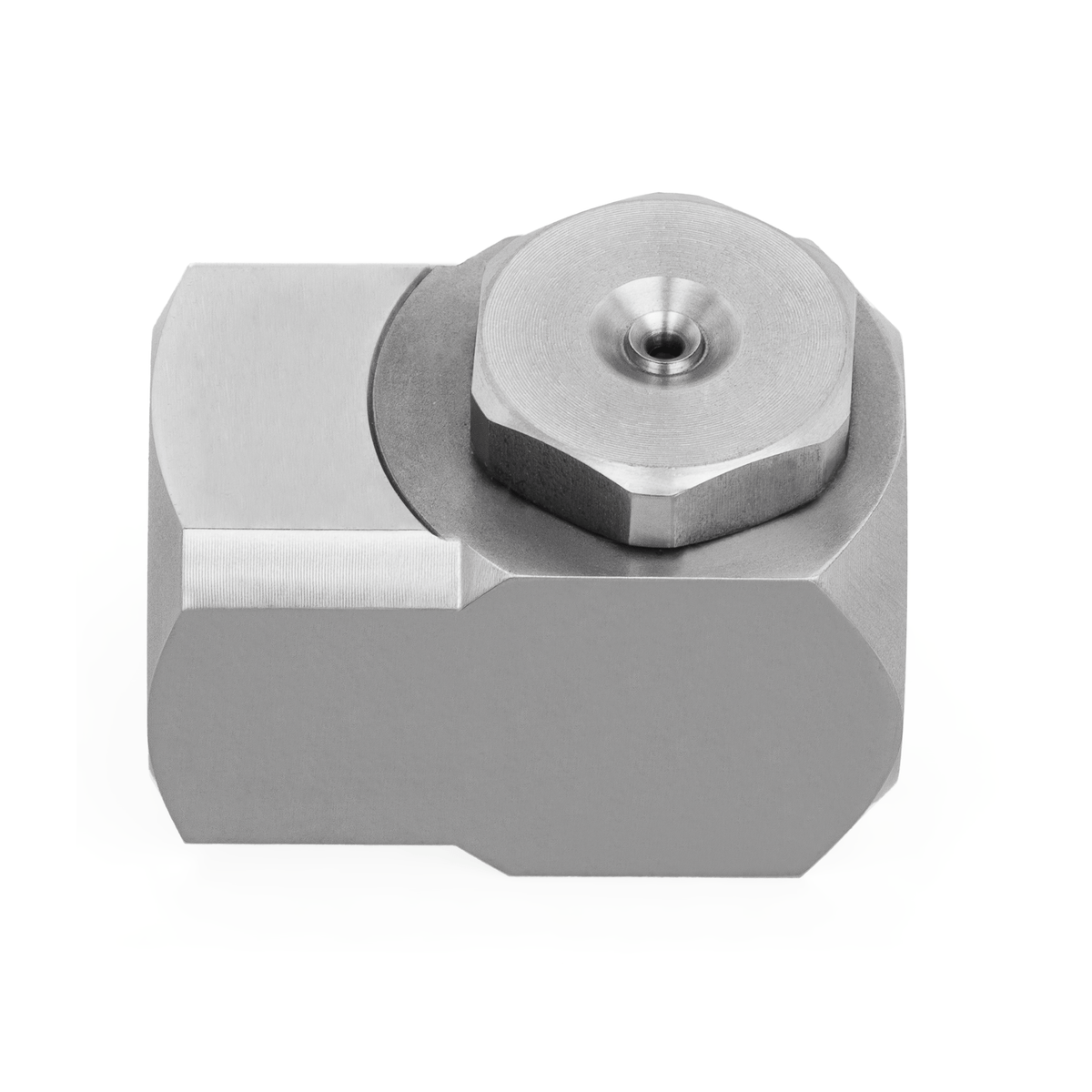

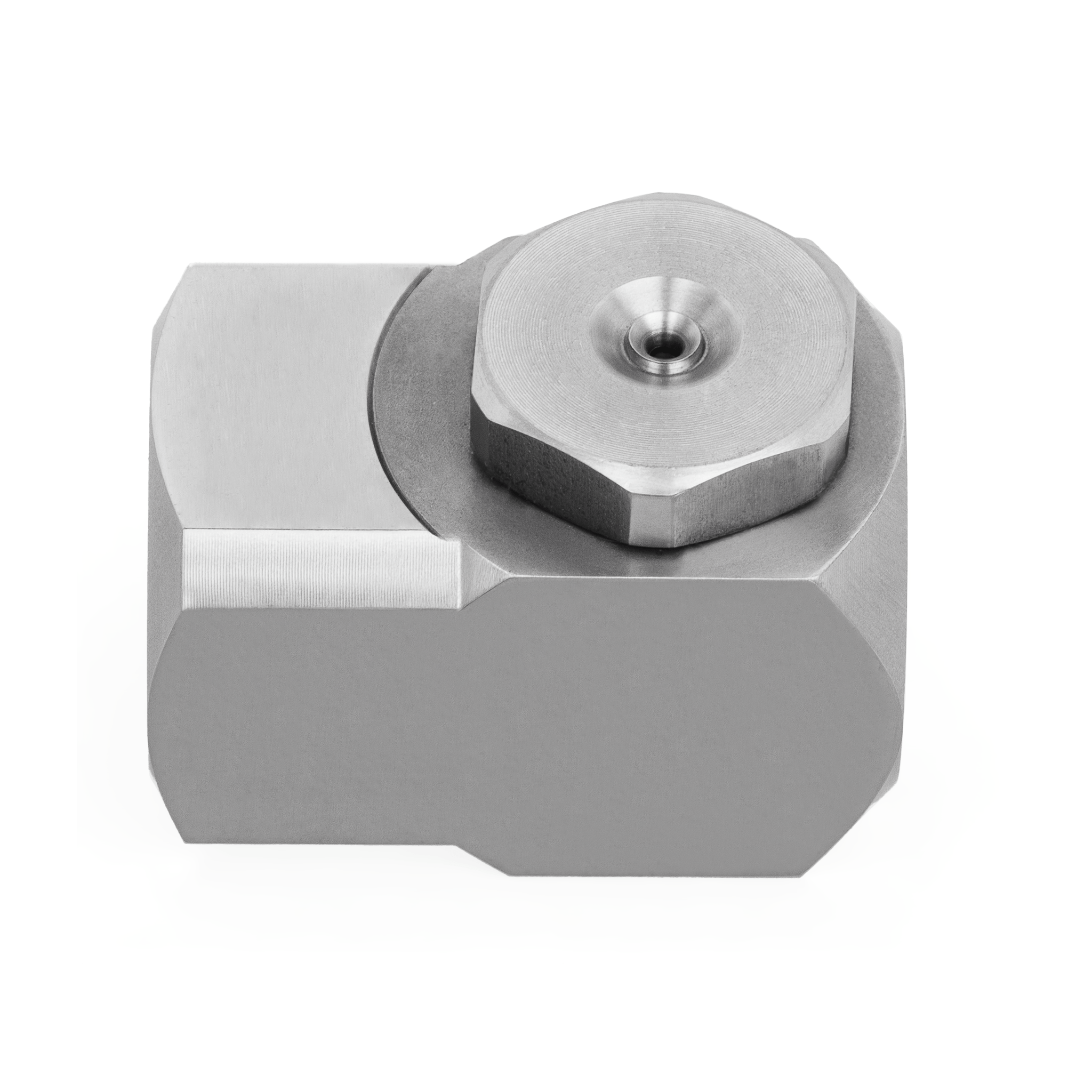

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPAX |

| Capacity Size | 15-15W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | FEMALE (F) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 6 |

| Orifice Diameter. Nom. (in) | 0.219 |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 32 |

| Length (in) | 1.250 |

| Inlet Dia. Nom. (in) | 0.234 |

| Max. Free Passage Dia. (mm) | 5.6 |

Description

Product Overview

A plant operator in the breweries & wineries facility uses the NPAX-15-15W-1/4-316 during specialty applications to achieve consistent liquid distribution across fermentation tanks. Constructed from 316l stainless steel, this nozzle resists corrosion and maintains structural integrity under acidic conditions common in beverage production. Its precision hollow cone spray pattern ensures uniform coverage, which helps optimize process efficiency and reduces waste. The 1/4-inch inlet size allows seamless integration with existing piping systems, facilitating straightforward installation and reliable operation.

Applications

In cooling & quenching processes, the nozzle delivers a controlled hollow cone spray that promotes rapid temperature reduction and minimizes thermal stress on components. Additionally, in dust & pollution control settings, its uniform atomization helps capture airborne particulates, improving air quality and maintaining compliance with environmental standards.

Industries

Sectors such as automotive, chemical processing, and steel & metals utilize this nozzle for its durability and consistent spray parameters under challenging operating conditions. The manufacturing & assembly and building materials industries also rely on its corrosion resistance and precise fluid distribution to support varied production requirements, while Energy facilities benefit from its robust design in harsh environments.