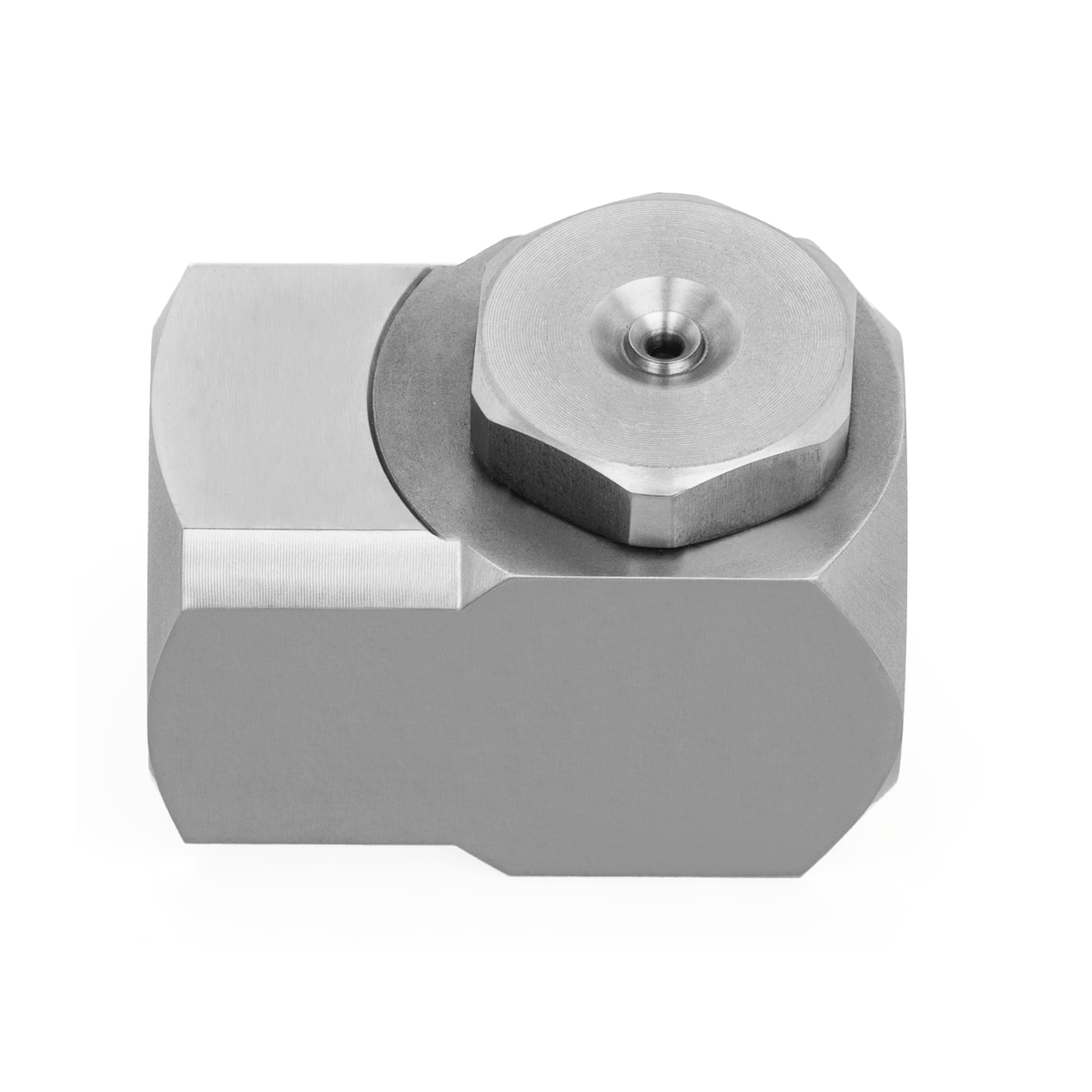

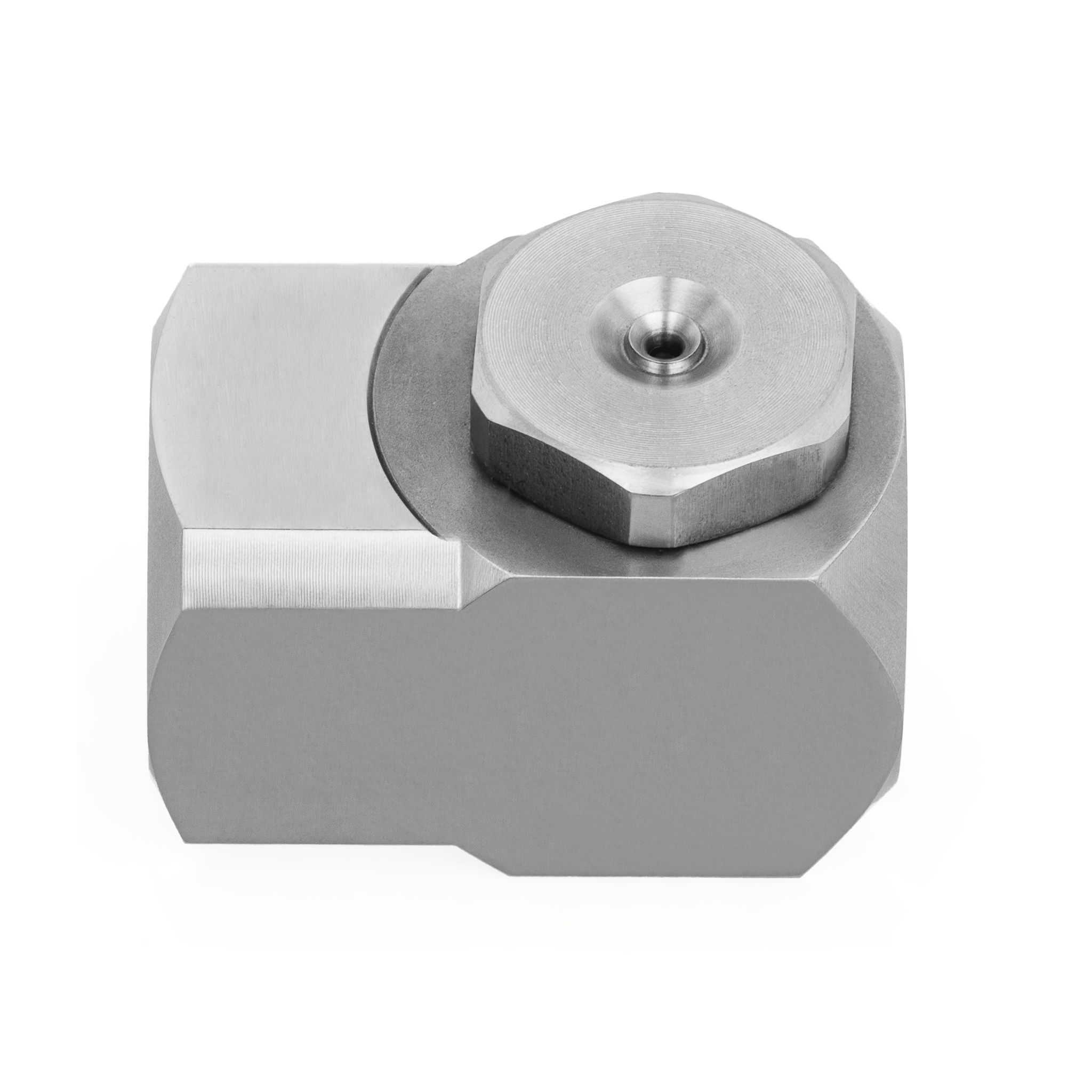

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPAX |

| Capacity Size | 10-15W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | FEMALE (F) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 4.8 |

| Orifice Diameter. Nom. (in) | 0.219 |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 32 |

| Length (in) | 1.250 |

| Inlet Dia. Nom. (in) | 0.188 |

| Max. Free Passage Dia. (mm) | 5.6 |

Description

Product Overview

A utilities coordinator in the chemical processing facility uses the NPAX-10-15W-1/4-316 during specialty applications to deliver a consistent hollow cone spray pattern essential for process stability. Constructed from 316L stainless steel, this nozzle resists corrosion in harsh chemical environments, extending service life and reducing downtime. The 1/4-inch inlet size allows easy integration into existing piping configurations, enabling precise flow control. Operators monitor spray uniformity and adjust parameters to maintain optimal coverage and efficient resource use.

Applications

This nozzle supports cooling & quenching operations by providing a uniform spray that controls temperature fluctuations and prevents thermal stress. Additionally, it is effective in dust & pollution control, where consistent atomization reduces airborne particulates and improves air quality in industrial settings.

Industries

Sectors such as chemical processing, steel & metals, and manufacturing & assembly rely on this nozzle for its durability and reliable spray performance under demanding conditions. The automotive, breweries & wineries, and meat & poultry industries also use it to meet specific process requirements that involve corrosive substances or precise fluid distribution.