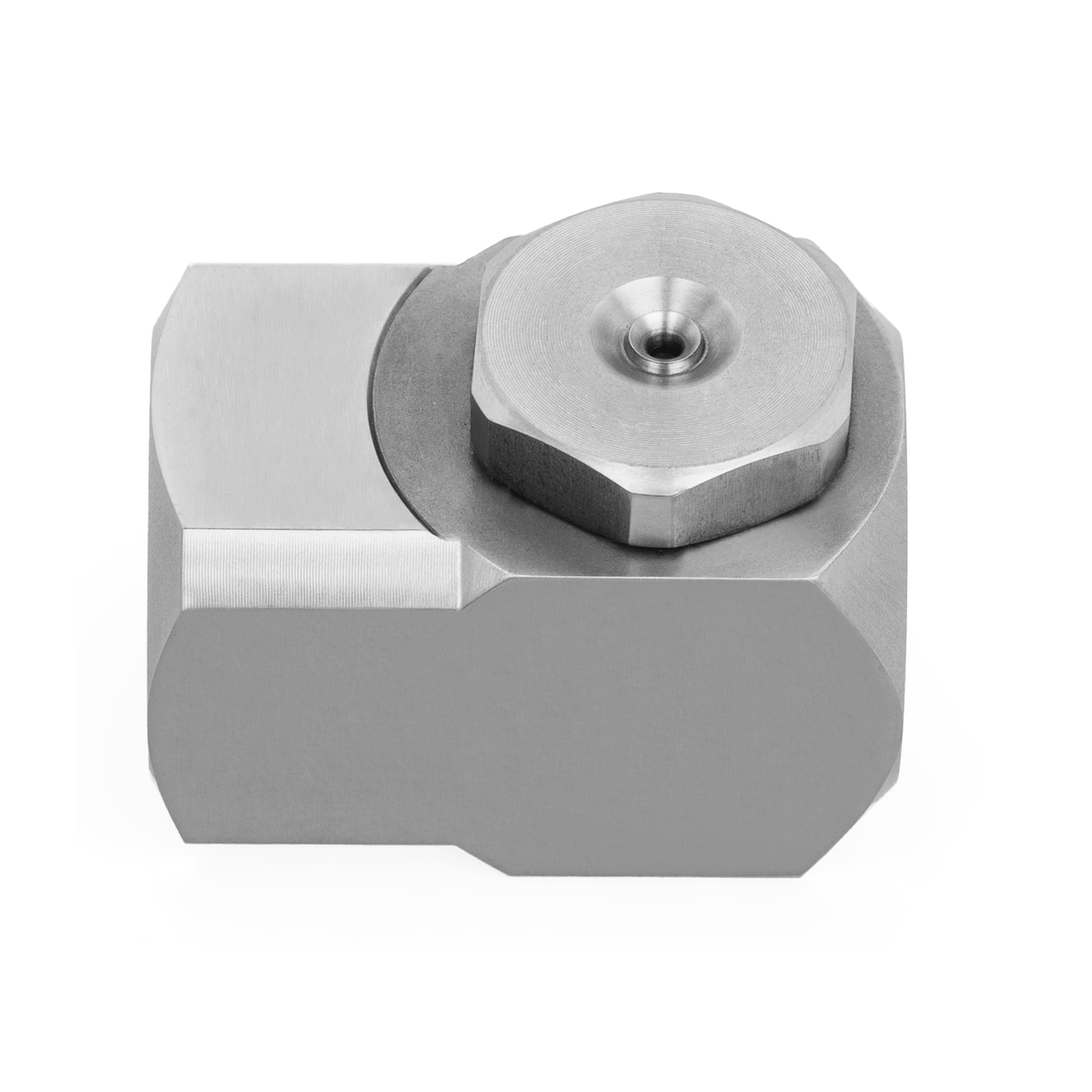

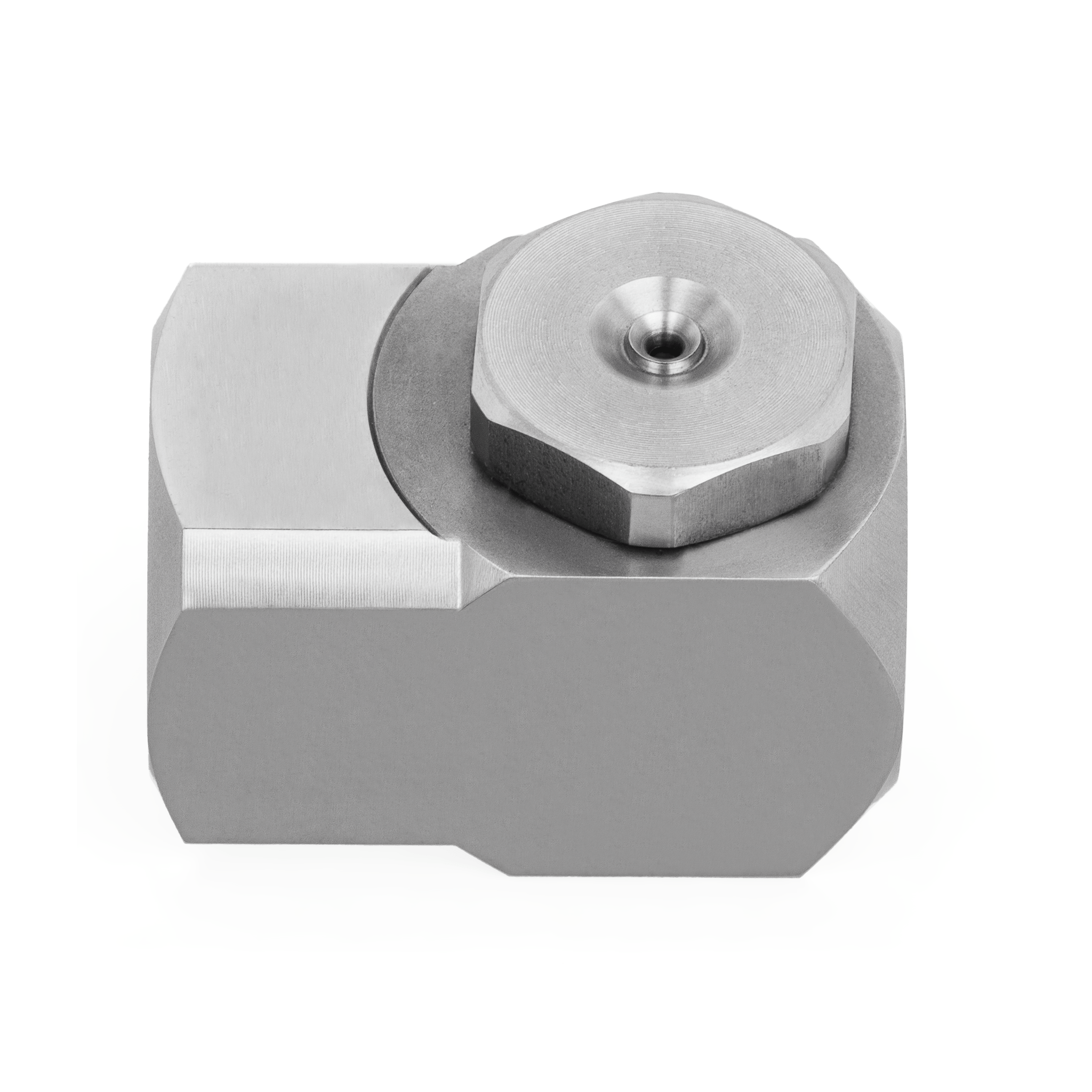

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPAX |

| Capacity Size | 10-10W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | FEMALE (F) |

| Material Composition Filter | 303/304 stainless steel |

| Orifice Diameter. Nom. (mm) | 5.2 |

| Orifice Diameter. Nom. (in) | 0.172 |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 37.5 |

| Length (in) | 1.469 |

| Inlet Dia. Nom. (in) | 0.203 |

| Max. Free Passage Dia. (mm) | 4.4 |

Description

Product Overview

Inside the building materials line's cooling & quenching stage, a plant operator relies on the NPAX-10-10W-3/8-SS to deliver a consistent hollow cone spray essential for controlling temperature during rapid cooling. Constructed from durable 303/304 stainless steel, the nozzle withstands corrosive environments while maintaining uniform droplet distribution. The operator monitors flow rates and spray coverage to ensure efficient quenching without material distortion. This precision nozzle supports stable process conditions by minimizing variability in spray performance.

Applications

In cooling & quenching processes, the NPAX-10-10W-3/8-SS provides even coverage that prevents localized overheating and improves yield quality. Additionally, the nozzle contributes to dust & pollution control by atomizing liquids that capture airborne particulates, reducing emissions in downstream operations.

Industries

Sectors such as automotive, chemical processing, and steel & metals incorporate the NPAX-10-10W-3/8-SS because it reliably handles corrosive fluids and maintains spray consistency under demanding conditions. Manufacturing & assembly and breweries & wineries also benefit from this nozzle's ability to deliver controlled spray patterns critical for process stability in both humidification and conditioning stages.