Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPAX |

| Capacity Size | 0.5-0.5W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | FEMALE (F) |

| Material Composition Filter | 303/304 stainless steel |

| Orifice Diameter. Nom. (mm) | 0.79 |

| Orifice Diameter. Nom. (in) | 0.047 |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 25.5 |

| Length (in) | 1.000 |

| Inlet Dia. Nom. (in) | 0.031 |

| Max. Free Passage Dia. (mm) | 1.2 |

Description

Product Overview

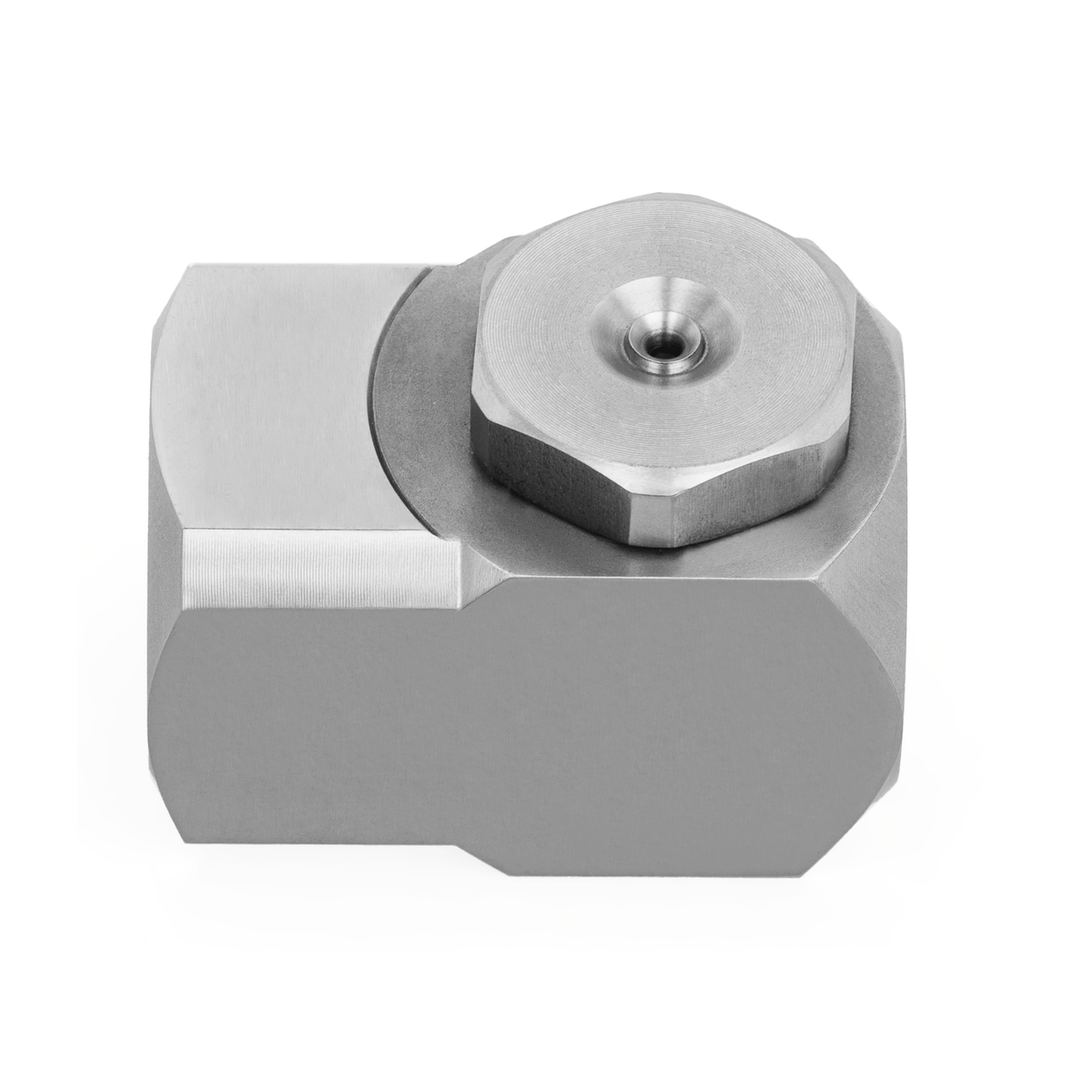

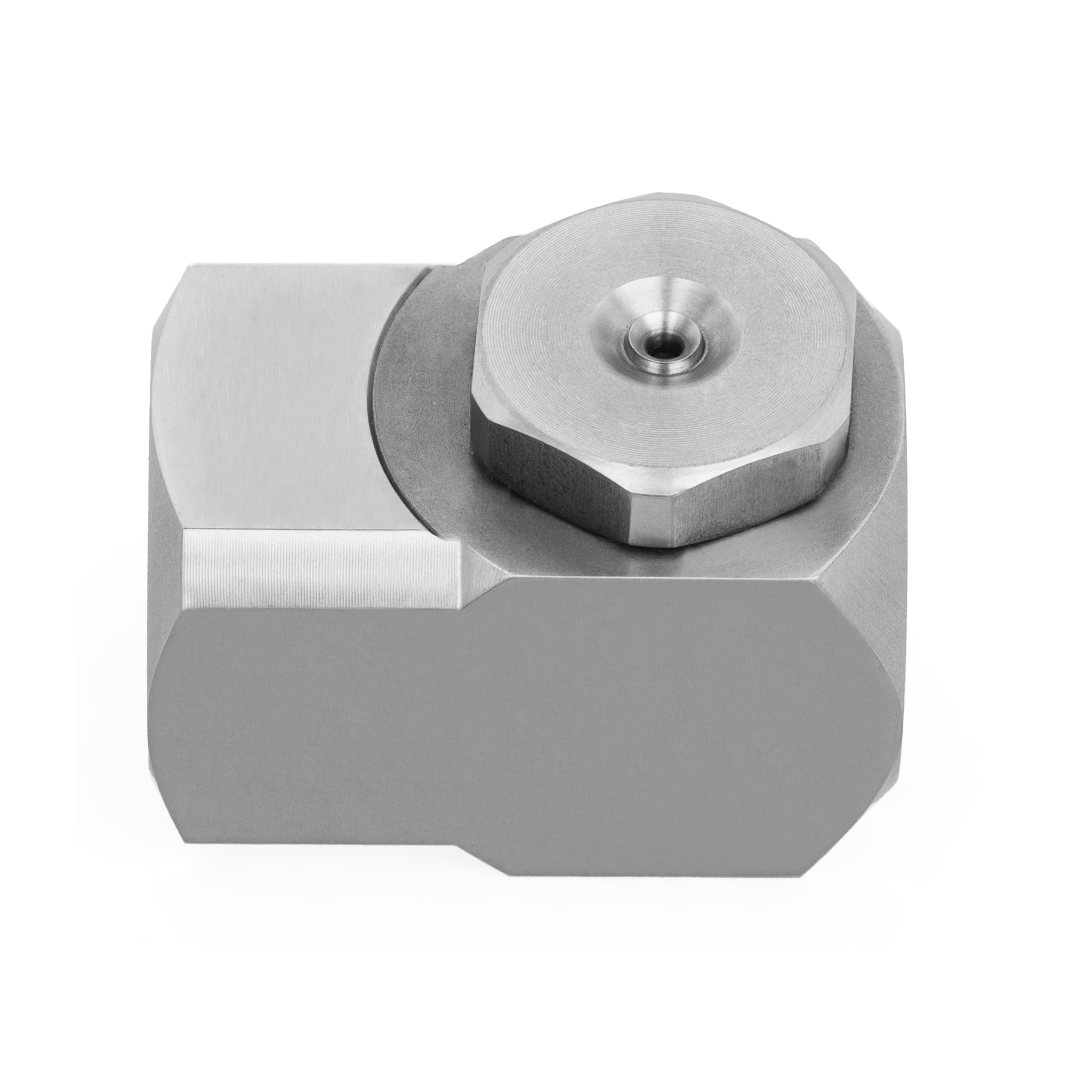

When manufacturing & assembly crews manage dust & pollution control, the NPAX-0.5-0.5W-1/8-SS lets each process engineer install a robust solution built from 303/304 stainless steel to withstand corrosive environments. The operator fits the nozzle with its 1/8 inlet into existing spray systems, ensuring a consistent hollow cone spray pattern that delivers uniform coverage. This precise spray reduces material waste and maintains controlled environmental conditions, enhancing overall process reliability. The stainless steel construction extends service life even under demanding industrial conditions.

Applications

In dust & pollution control systems, the nozzle ensures even distribution of spray droplets to suppress airborne contaminants effectively. Additionally, its role in humidification & conditioning helps maintain stable humidity levels critical for sensitive manufacturing processes, preventing product degradation and improving operational consistency.

Industries

The NPAX-0.5-0.5W-1/8-SS is widely used in automotive and steel & metals sectors where precise spray control is necessary for surface treatments and cooling. Chemical processing and breweries & wineries also rely on this nozzle for corrosion-resistant operation, while building materials and meat & poultry industries benefit from its durability in environments requiring consistent spray performance. Energy and manufacturing & assembly facilities favor the nozzle for its adaptability across varied