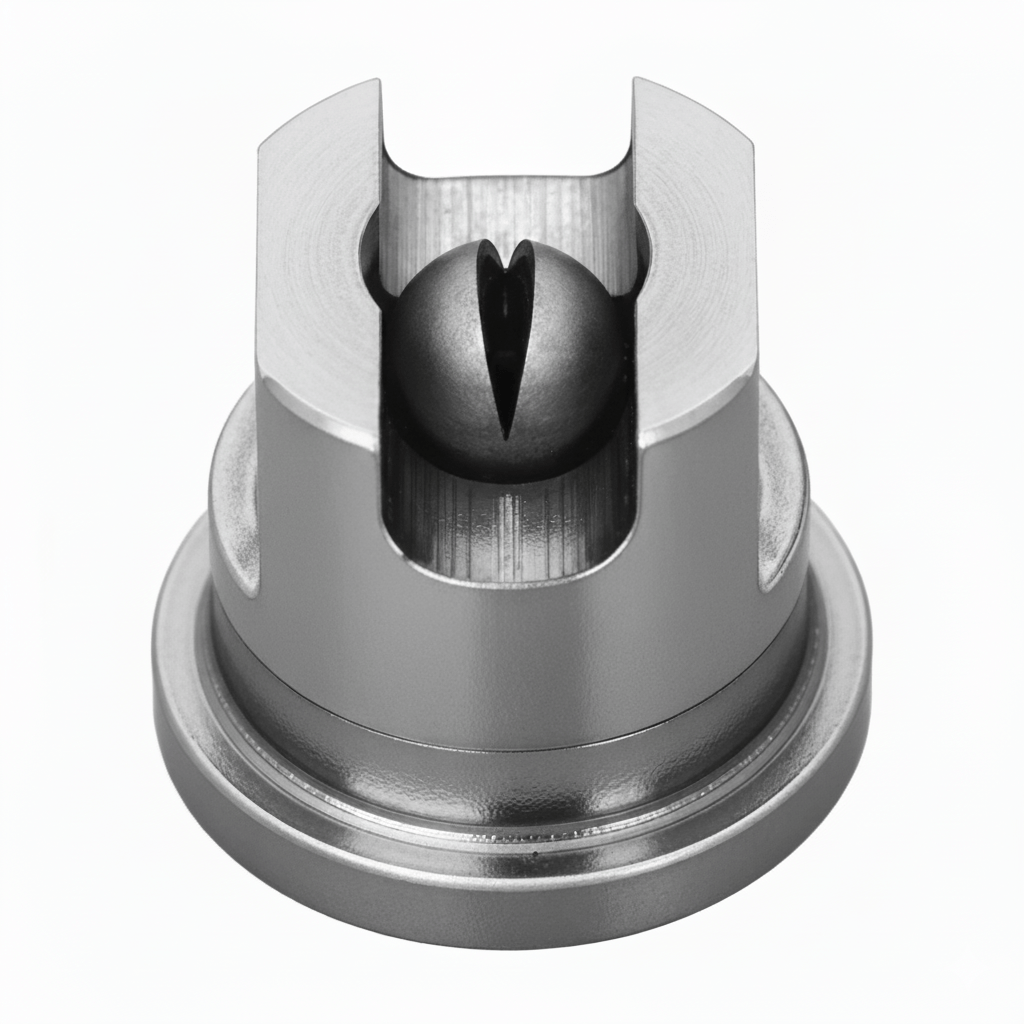

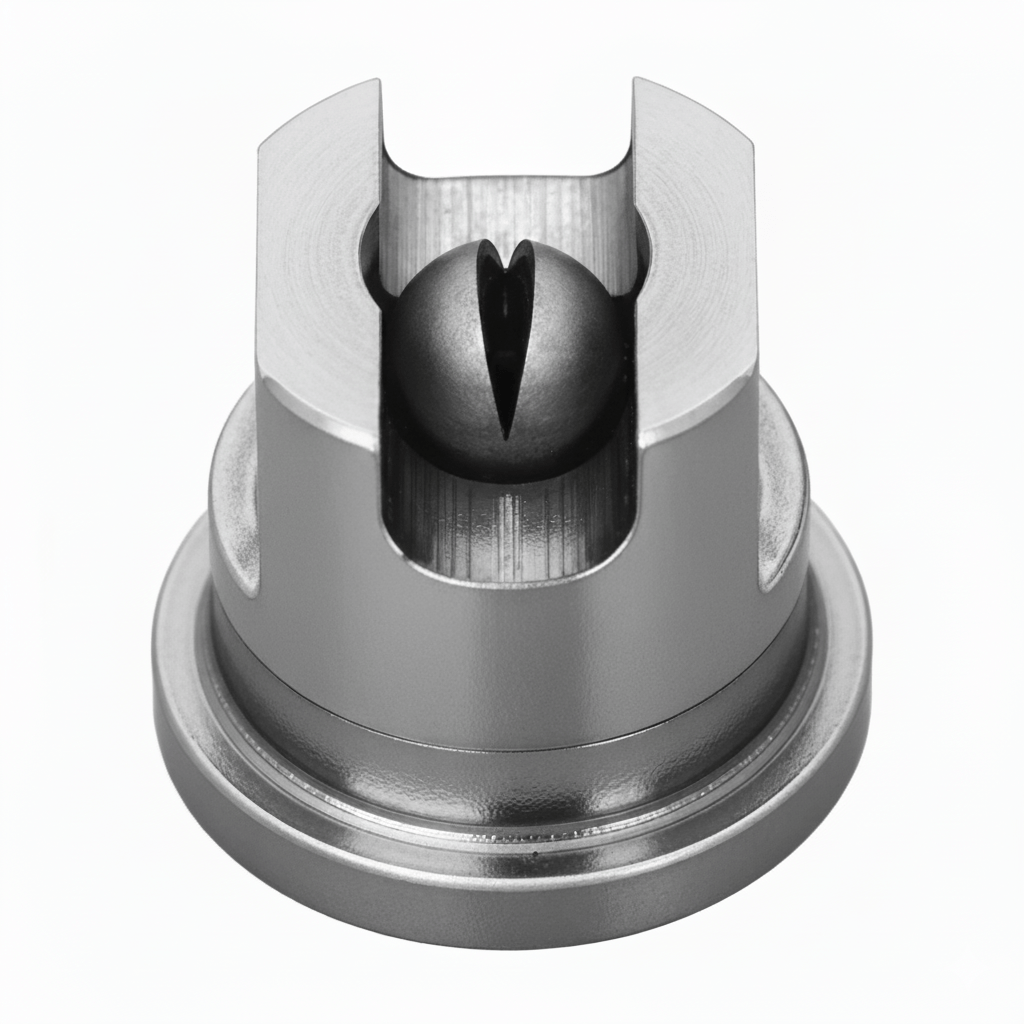

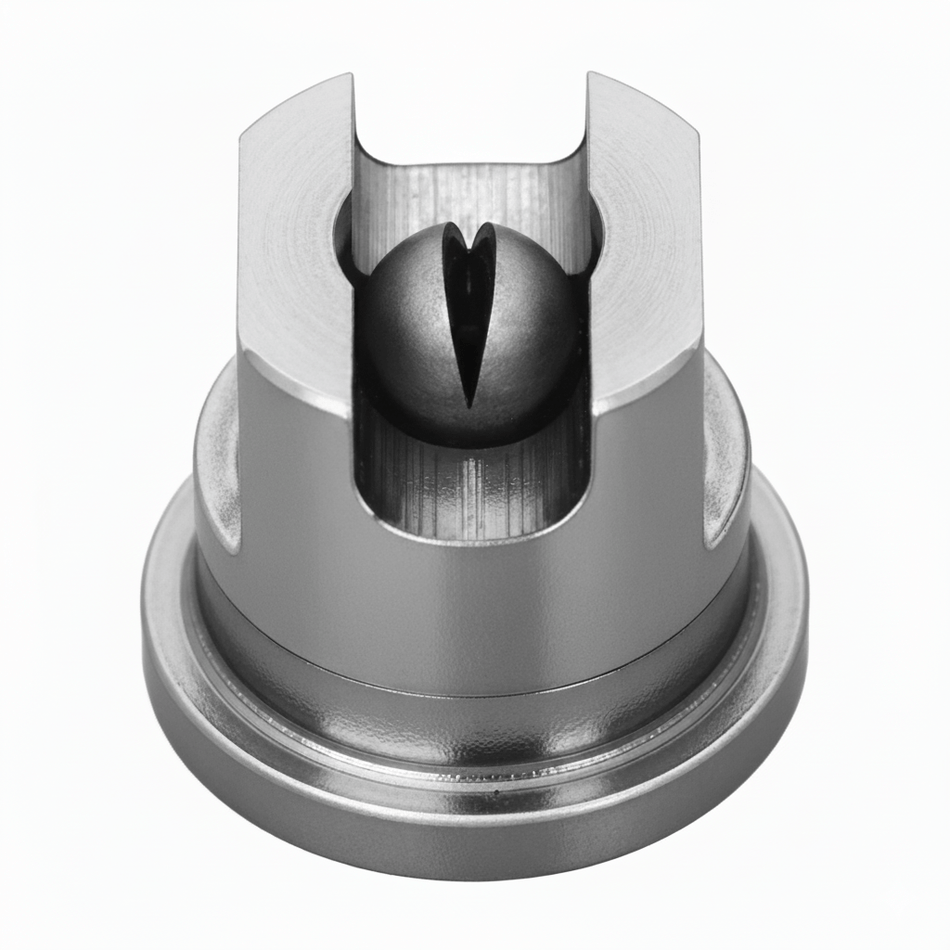

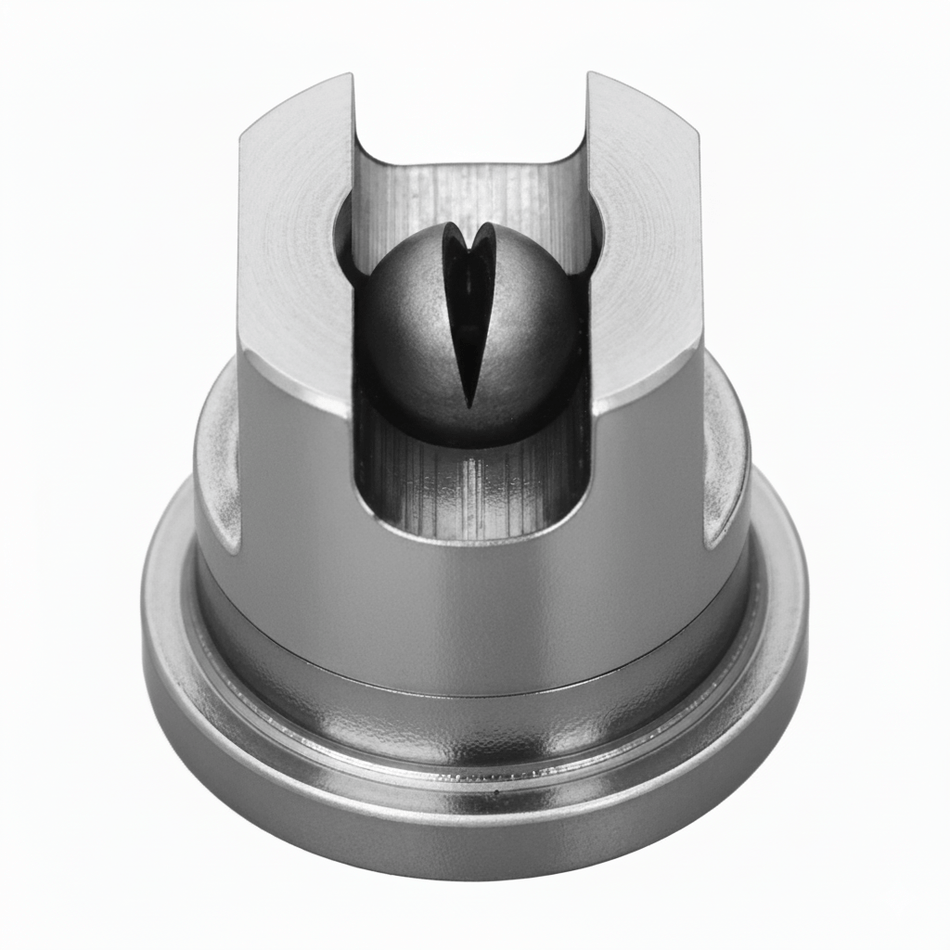

Product Parameters

| Product Family | High Pressure |

|---|---|

| Product Series | NP-TC |

| Capacity Size | 6 |

| Material Composition Filter | Tungsten carbide insert |

| Spray Angle at Rated Pressure (PSI) | 95 |

Description

Product Overview

During high pressure on a paint & viscous site, process engineers trust the NP9506-TC to deliver a consistent and uniform spray pattern essential for coating applications. The nozzle's tungsten carbide insert resists wear and corrosion, allowing operators to maintain precise flow rates over extended production runs. By integrating the NP9506-TC, technicians achieve repeatable coverage that minimizes material waste and reduces downtime caused by nozzle degradation. This reliability supports tight process controls and stable surface finishes in demanding environments.

Applications

In cleaning & washing operations, the NP9506-TC nozzle provides uniform spray distribution that improves contaminant removal without excessive water use. For coating & surface treatment, its high pressure capability enables even application of viscous materials, enhancing adhesion and curing outcomes critical for downstream manufacturing steps.

Industries

Automotive, building materials, and steel & metals industries rely on the NP9506-TC nozzle for its durability and precision in both abrasive and corrosive environments. Food & beverage and mining sectors also benefit from consistent performance during high pressure tasks, where maintaining process integrity and minimizing downtime are essential.