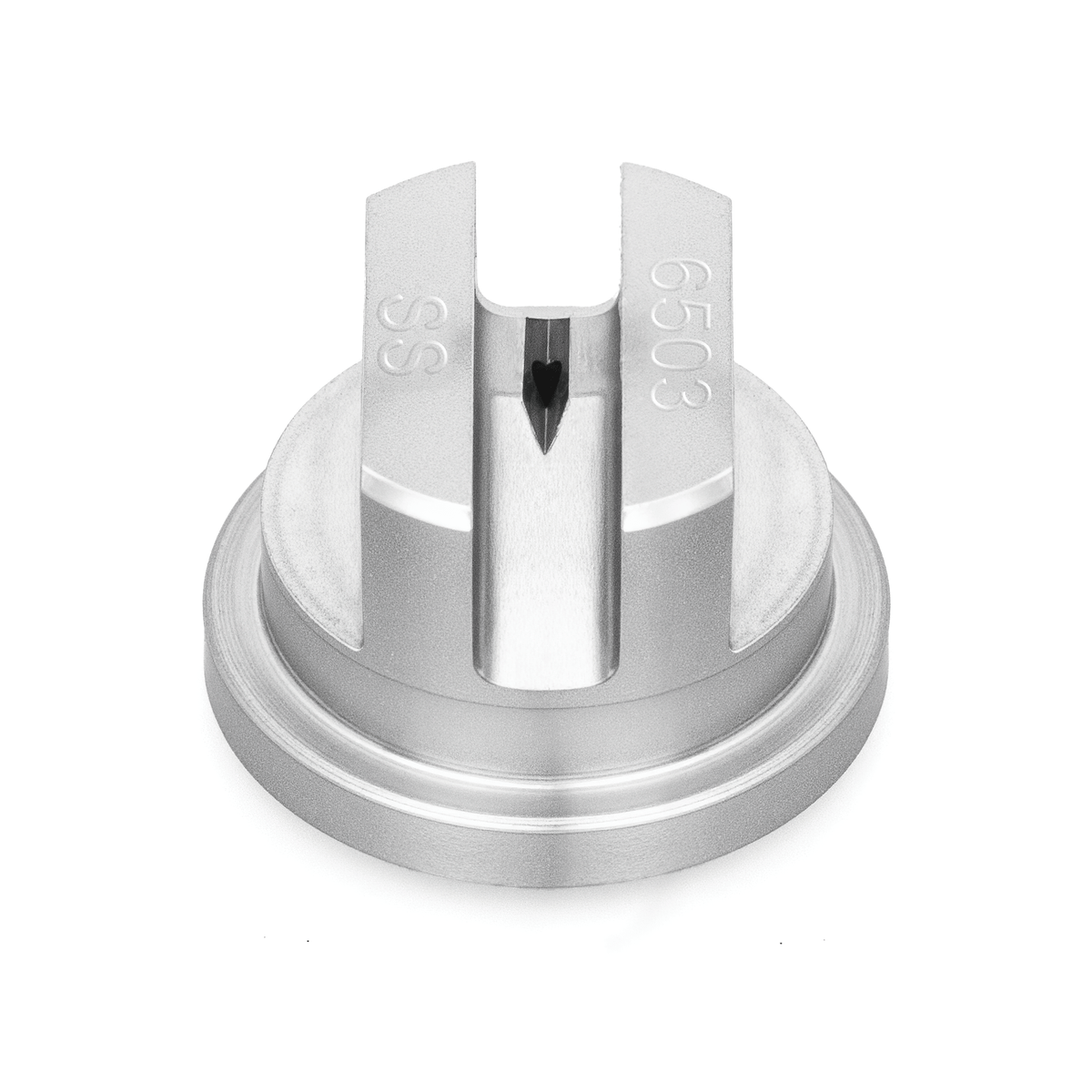

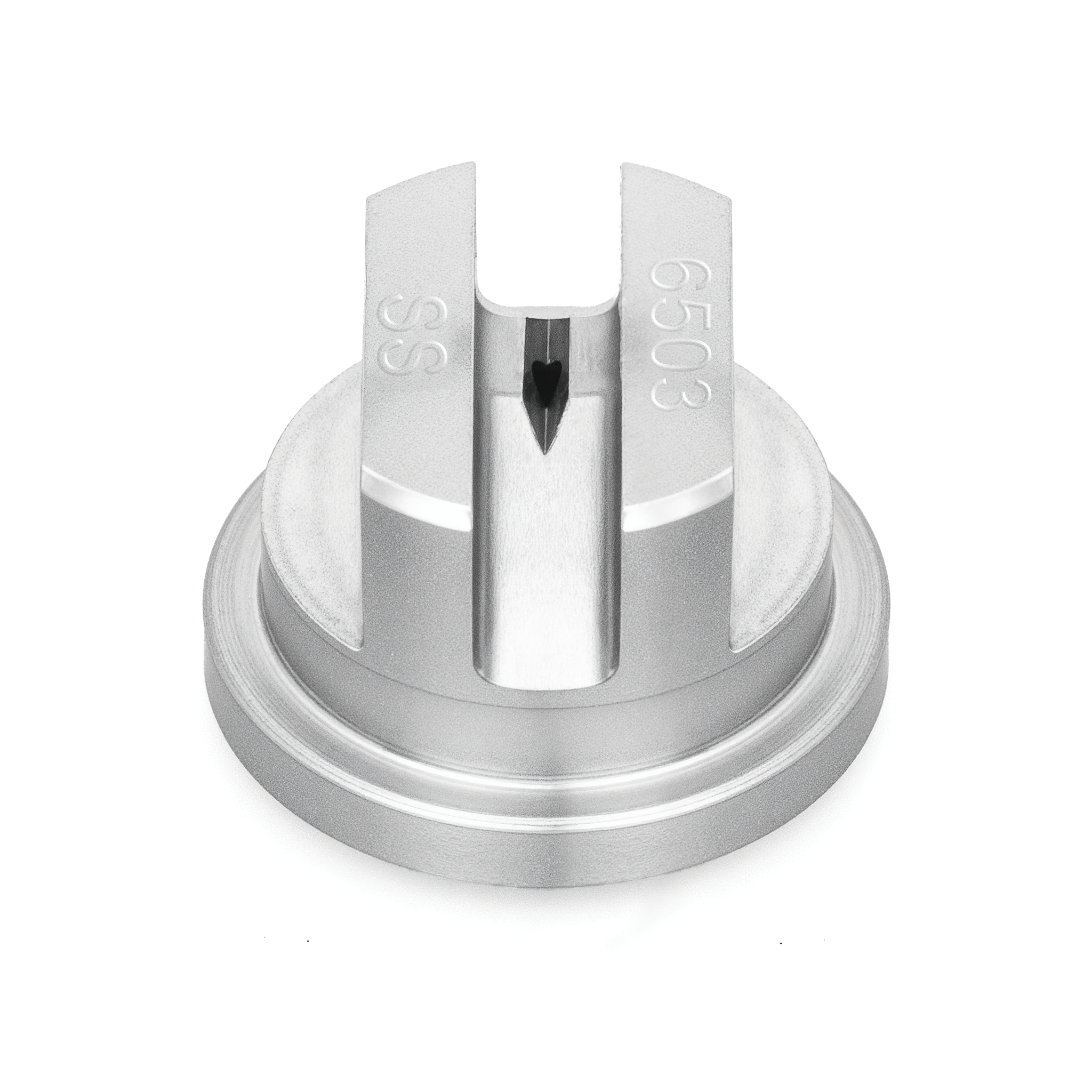

Product Parameters

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 70 |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 5.2 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Equivalent Orifice Diameter (in) | 0.203 |

| Spray Angle at Rated Pressure (PSI) | 95 |

Description

Product Overview

When engineered wood crews manage service & maintenance shops, the NP3U-9570-316 lets each process engineer achieve consistent coverage through its precision projet 3x modular unit assembly design. Constructed from 316L stainless steel, the nozzle withstands corrosion in harsh service environments, ensuring longevity and reliability. Operators value the uniform spray pattern for reducing material waste and maintaining strict quality control. This nozzle supports repeatable output, which is critical for maintaining process standards across multiple shifts.

Applications

In cleaning & washing operations, the NP3U-9570-316 delivers a controlled spray that improves debris removal while minimizing water usage. Its consistent output also benefits downstream drying & blow-off stages by enabling faster surface preparation and reducing cycle times.

Industries

Sectors such as automotive, steel & metals, and food & beverage rely on the NP3U-9570-316 because its material construction and spray consistency meet rigorous demands for corrosion resistance and precise fluid application. These industries require reliable nozzles for processes like coating & surface treatment and humidification, where controlled liquid distribution directly affects product quality and operational efficiency.