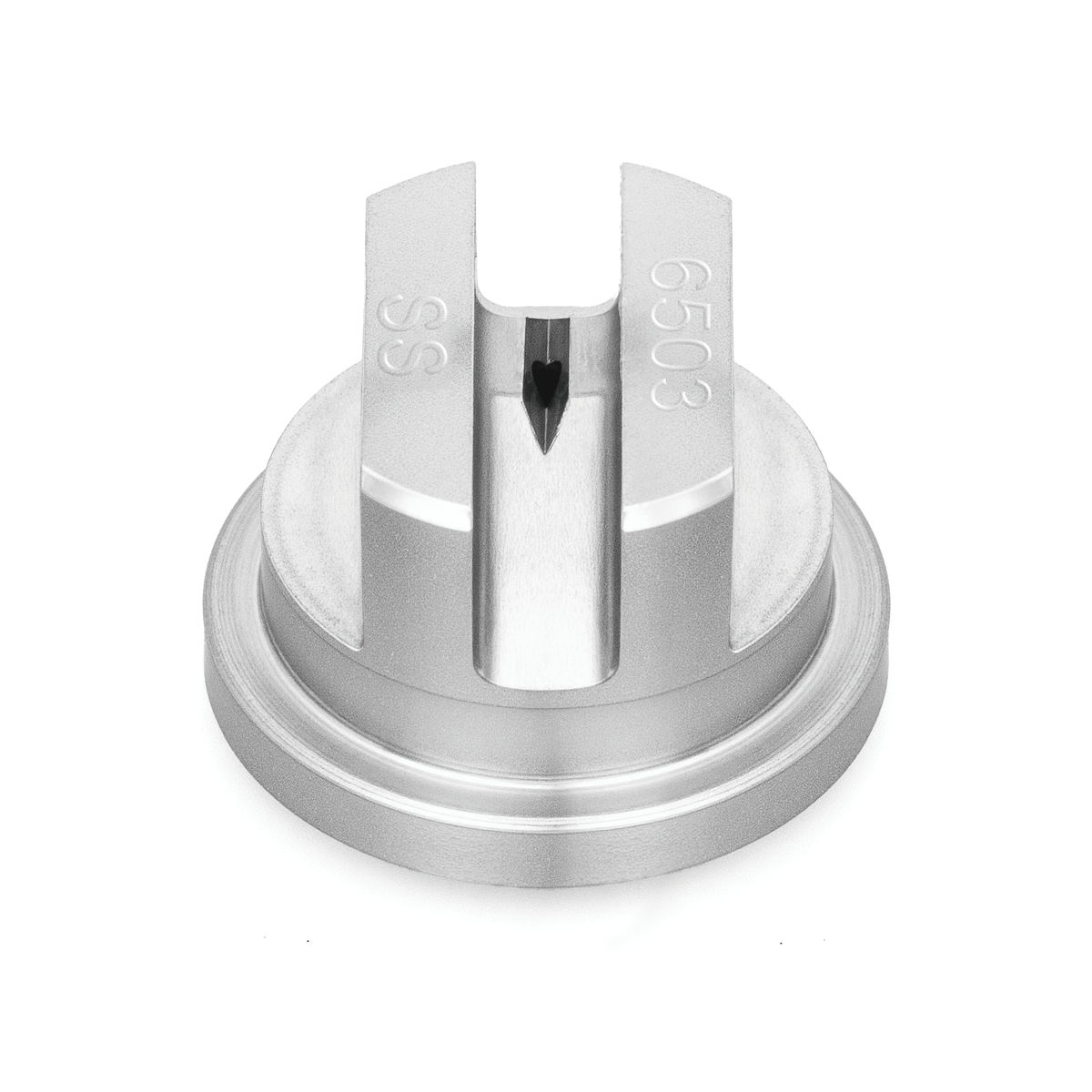

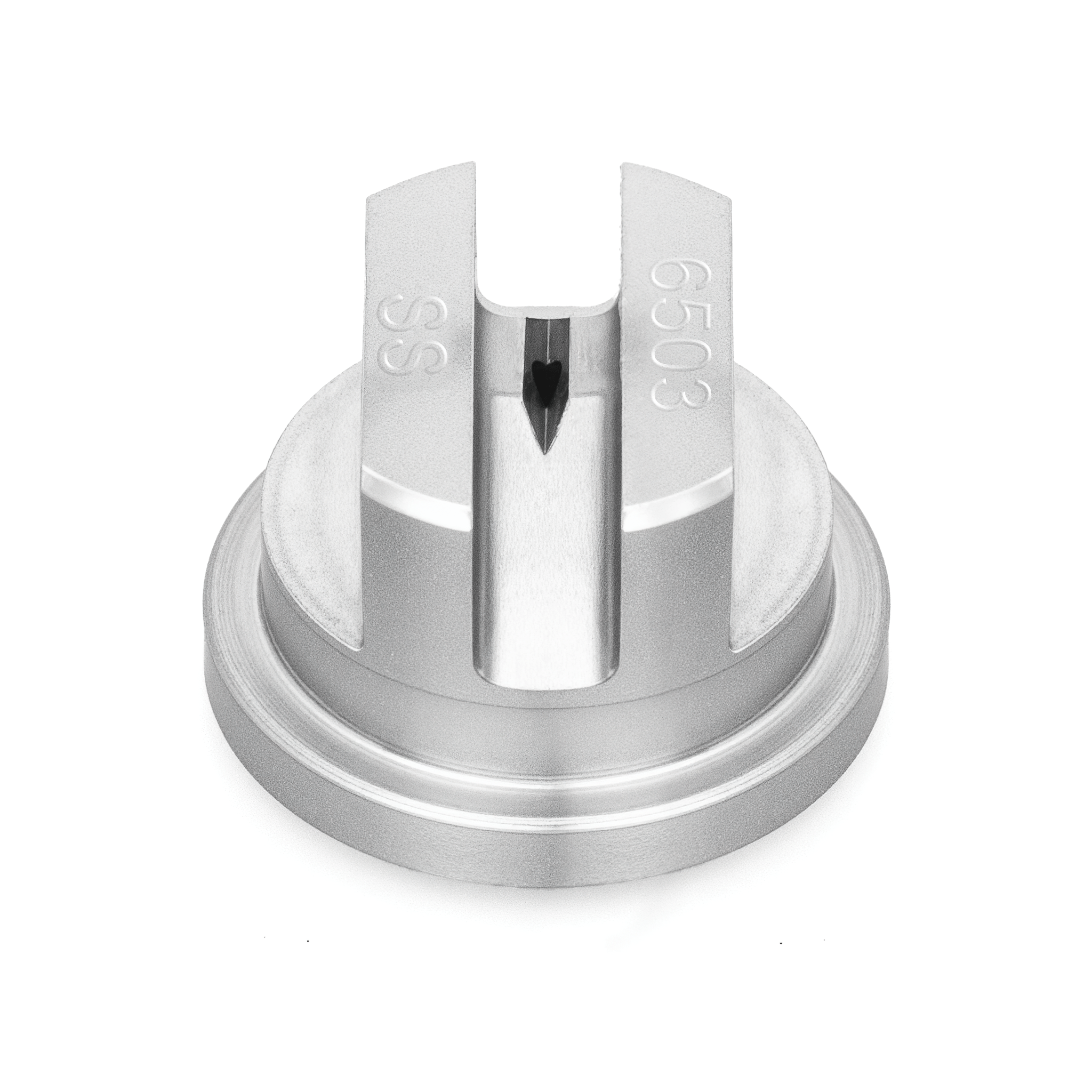

Product Parameters

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 20 |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 2.8 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Equivalent Orifice Diameter (in) | 0.112 |

| Spray Angle at Rated Pressure (PSI) | 95 |

Description

Product Overview

Inside the steel & metals line's coating & surface treatment stage, a quality manager relies on the NP3U-9520-316 to deliver consistent, uniform spray coverage critical for achieving exact coating thickness. The operator integrates this 316L stainless steel nozzle into the modular assembly, ensuring corrosion resistance under harsh conditions. Its precision projet 3x design stabilizes flow patterns, enabling repeatable results that reduce material waste and rework. Regular maintenance confirms the nozzle maintains tight spray uniformity, supporting quality control benchmarks.

Applications

In processes involving cleaning & washing, the NP3U-9520-316 facilitates thorough surface preparation by producing a uniform spray that removes contaminants effectively without damaging components. Additionally, its role in coating & surface treatment ensures even application of protective layers, enhancing product durability and downstream handling.

Industries

This nozzle is preferred in industries such as automotive, mining, and food & beverage where corrosion resistance and spray precision are vital for maintaining production standards. Sectors like breweries & wineries and building materials also utilize the NP3U-9520-316 to meet their specific requirements for reliable, consistent spraying in both sanitary and abrasive environments.