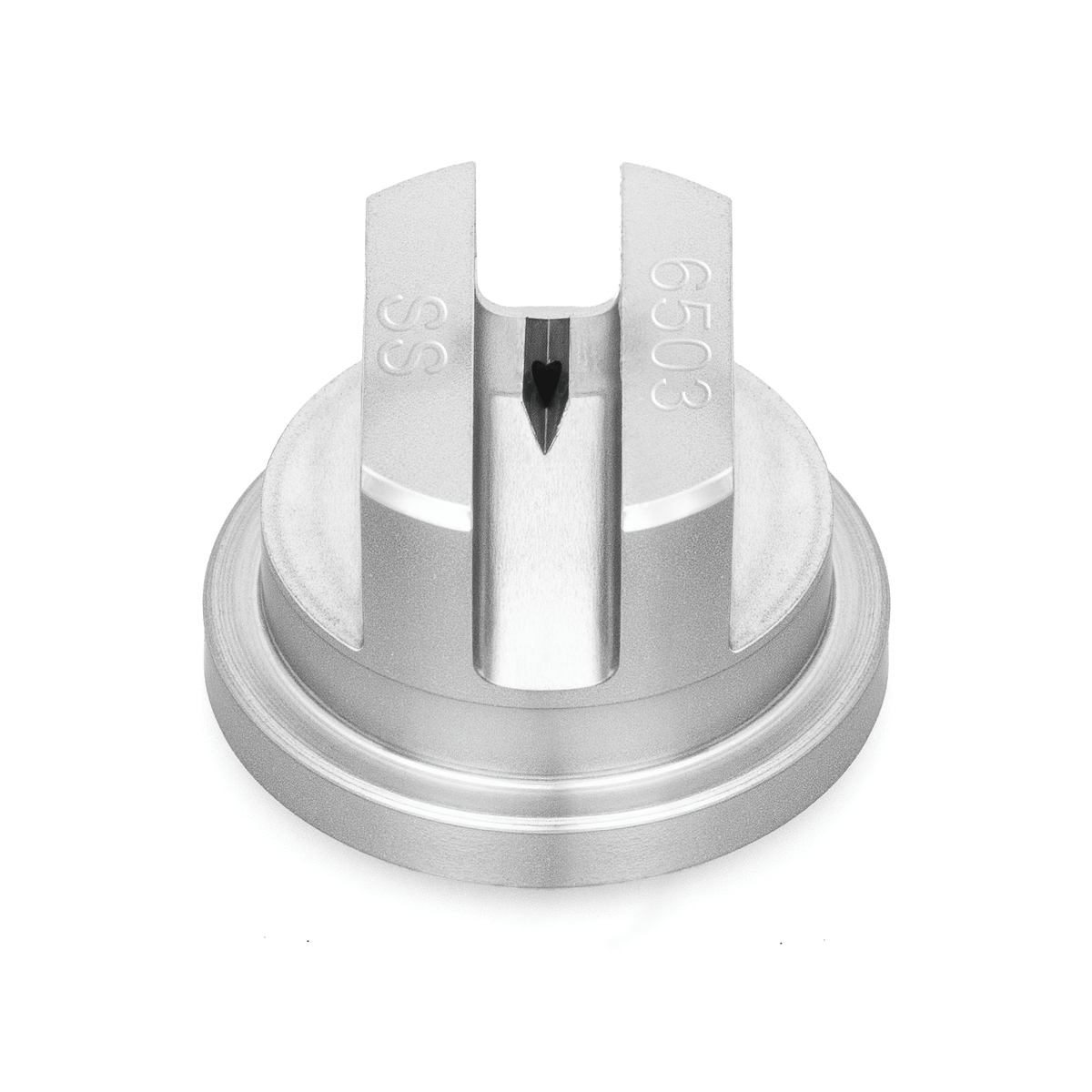

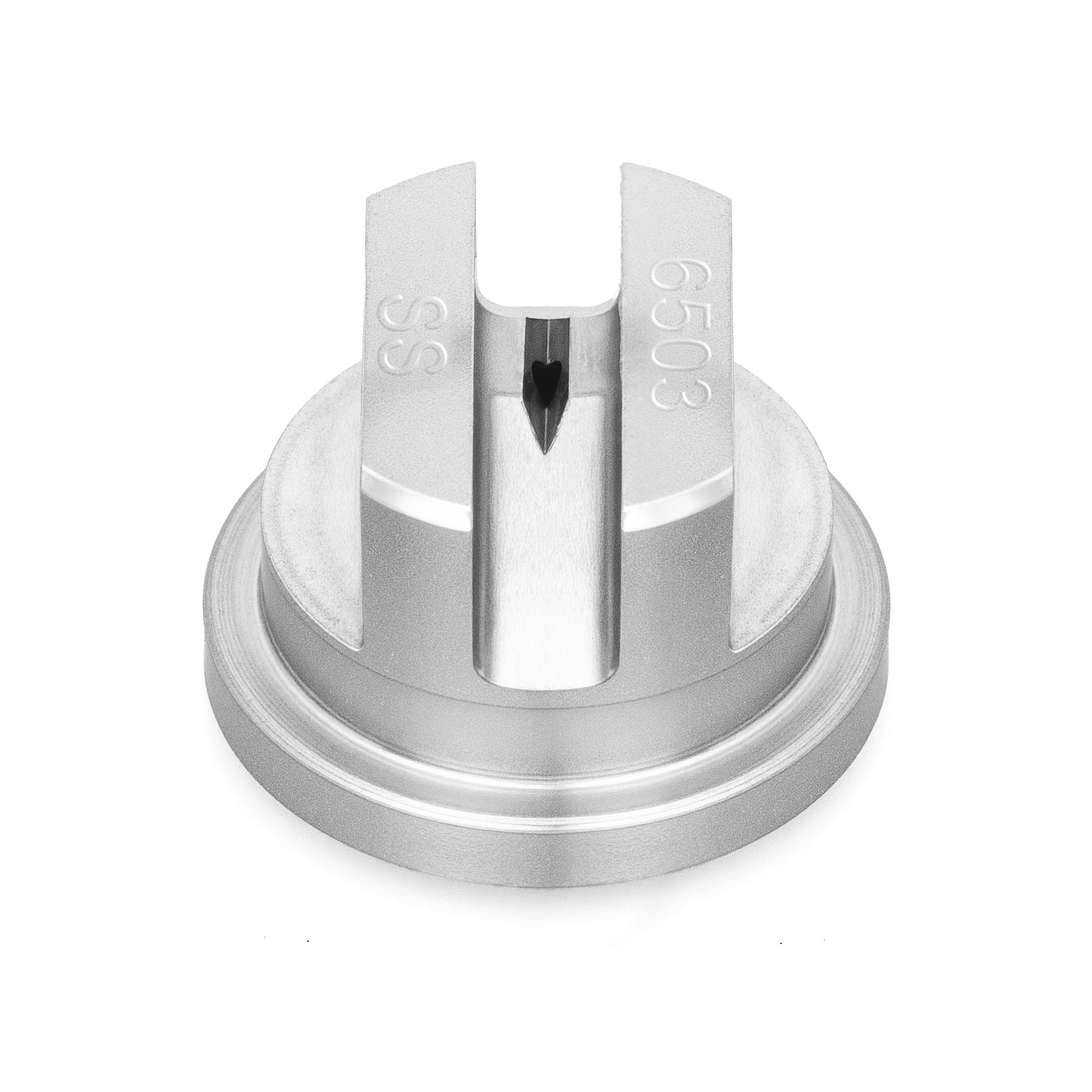

Product Parameters

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 15 |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 2.5 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Equivalent Orifice Diameter (in) | 0.097 |

| Spray Angle at Rated Pressure (PSI) | 95 |

Description

Product Overview

During drying & blow-off on a detailing & automotive care site, maintenance supervisors trust the NP3U-9515-316 to deliver consistent and uniform spray coverage. Constructed from 316L stainless steel, this nozzle resists corrosion even in harsh chemical environments, ensuring durability over long service intervals. Operators install the precision projet 3x modular unit assembly nozzle to achieve controlled fluid distribution, which reduces drying time and enhances the quality of surface treatment. The nozzle's design supports repeatable performance, helping to maintain process efficiency and minimize waste.

Applications

In cleaning & washing operations, the NP3U-9515-316 enables thorough removal of contaminants without damaging sensitive surfaces, improving downstream coating adhesion. Its performance in cooling & quenching ensures rapid temperature control, which is critical for maintaining material integrity during manufacturing cycles.

Industries

Sectors such as automotive, building materials, and food & beverage rely on this nozzle's corrosion resistance and consistent spray pattern to optimize processes in environments exposed to abrasive or corrosive agents. Mining, steel & metals, and bakery & confectionery industries also benefit from its robust construction and adaptability across multiple production stages.