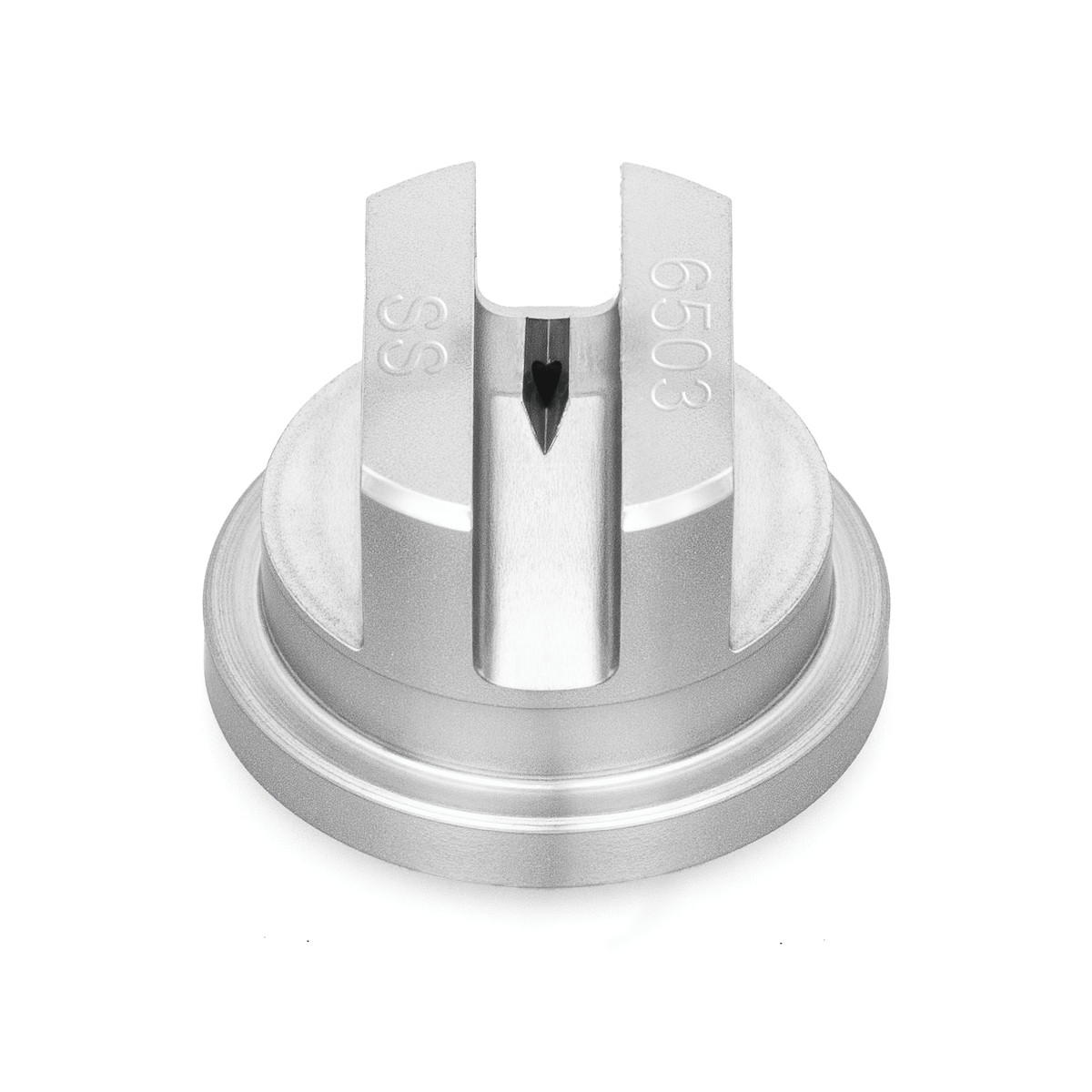

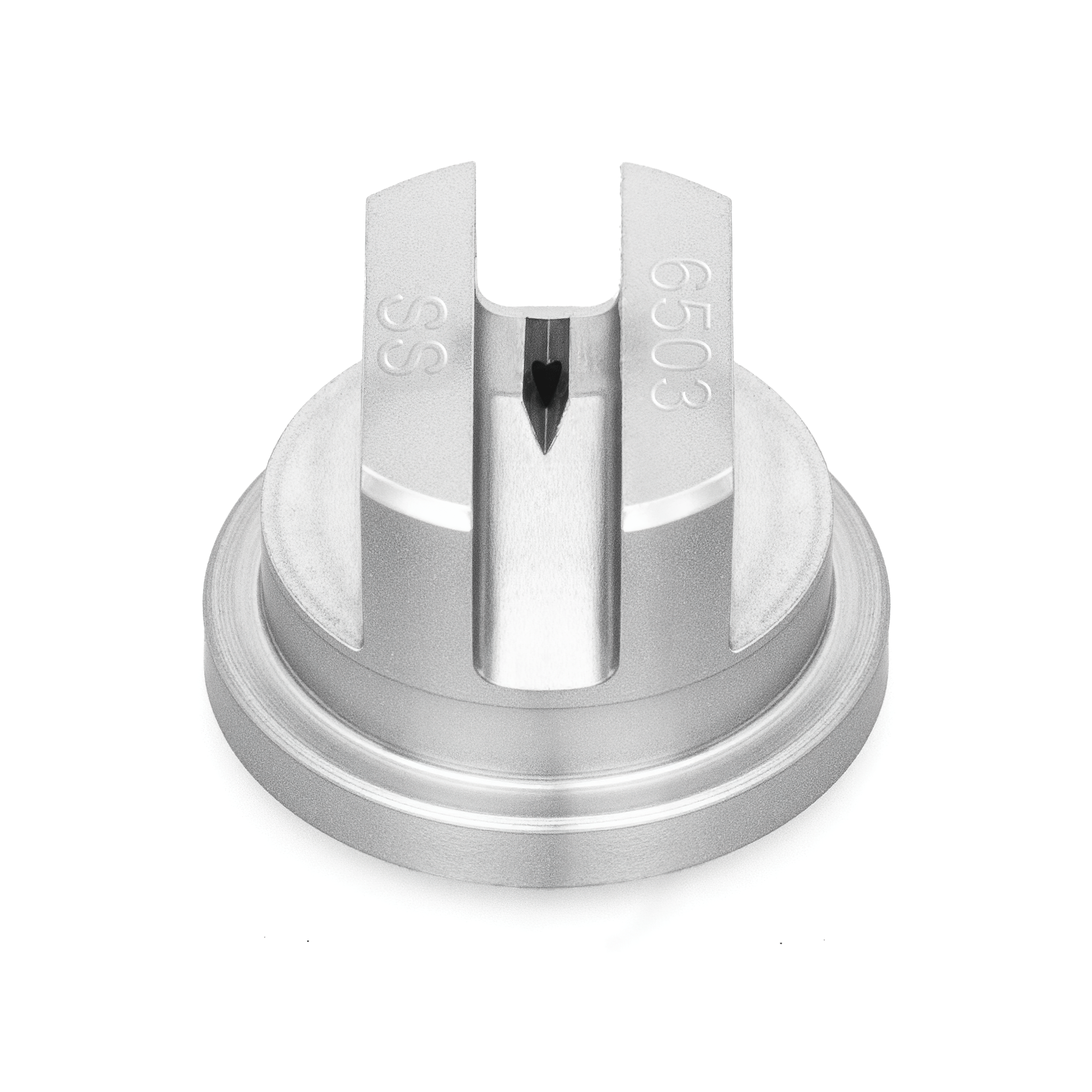

Product Parameters

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 10 |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 2.0 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Equivalent Orifice Diameter (in) | 0.079 |

| Spray Angle at Rated Pressure (PSI) | 95 |

Description

Product Overview

Inside the meat & poultry line's trucking & fleet wash stage, a process engineer relies on the NP3U-9510-316 to deliver consistent spray coverage using its precision projet 3x modular design. Constructed from 316L stainless steel, the nozzle withstands corrosive cleaning agents while maintaining dimensional stability. The uniform spray pattern enhances wash efficiency, reducing residue and downtime during fleet maintenance. This robust assembly supports repeatable performance critical for high-throughput wash cycles.

Applications

The nozzle's design is integral to cleaning & washing operations where consistent fluid distribution ensures thorough removal of contaminants. Additionally, its use in coating & surface treatment helps achieve uniform application layers, improving downstream process quality and reducing material waste.

Industries

Automotive, mining, and steel & metals sectors often specify this nozzle for its corrosion resistance and durability under harsh conditions. The food & beverage, bakery & confectionery, and beverage bottling & packaging industries value the material compatibility and spray uniformity that support hygiene and compliance standards during processing.