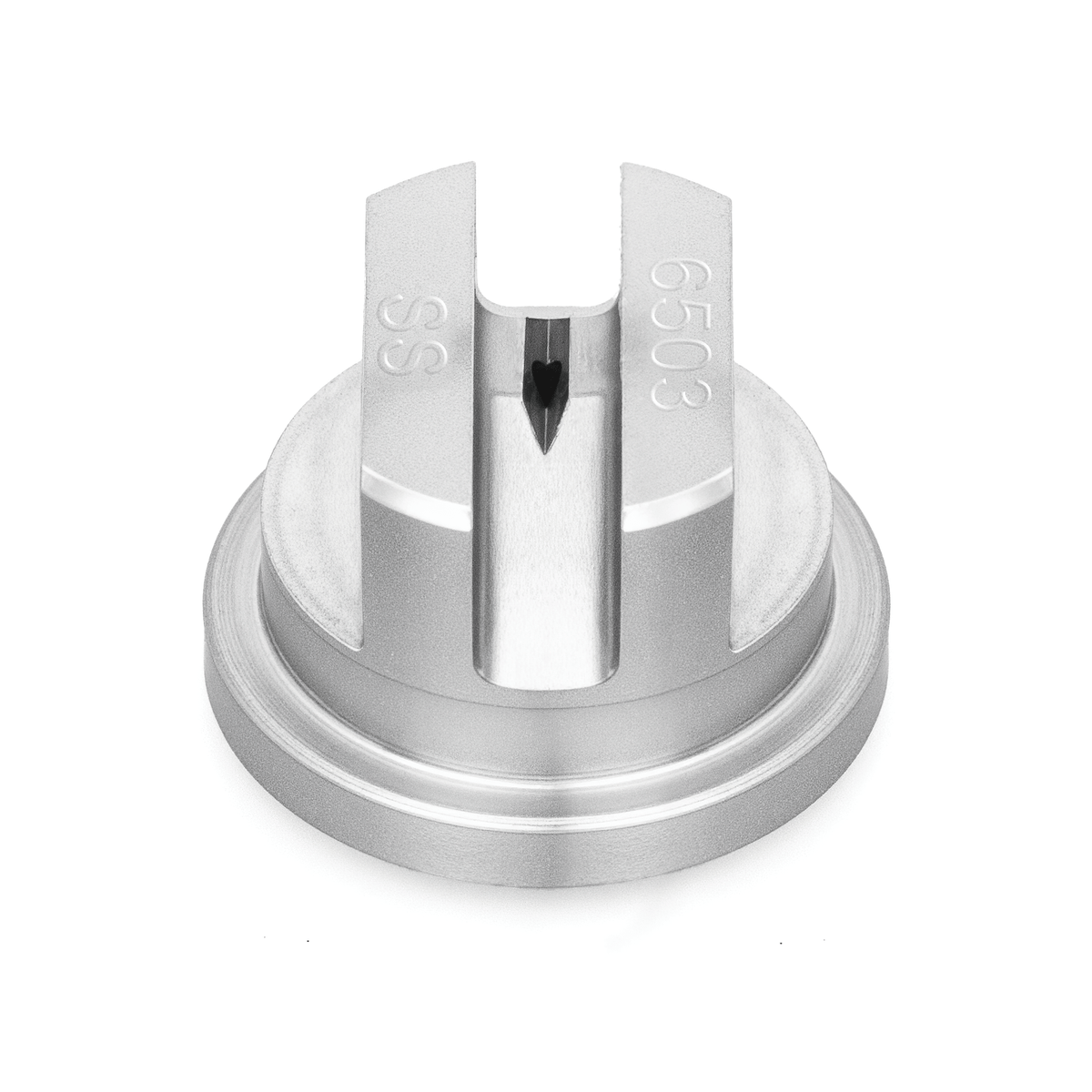

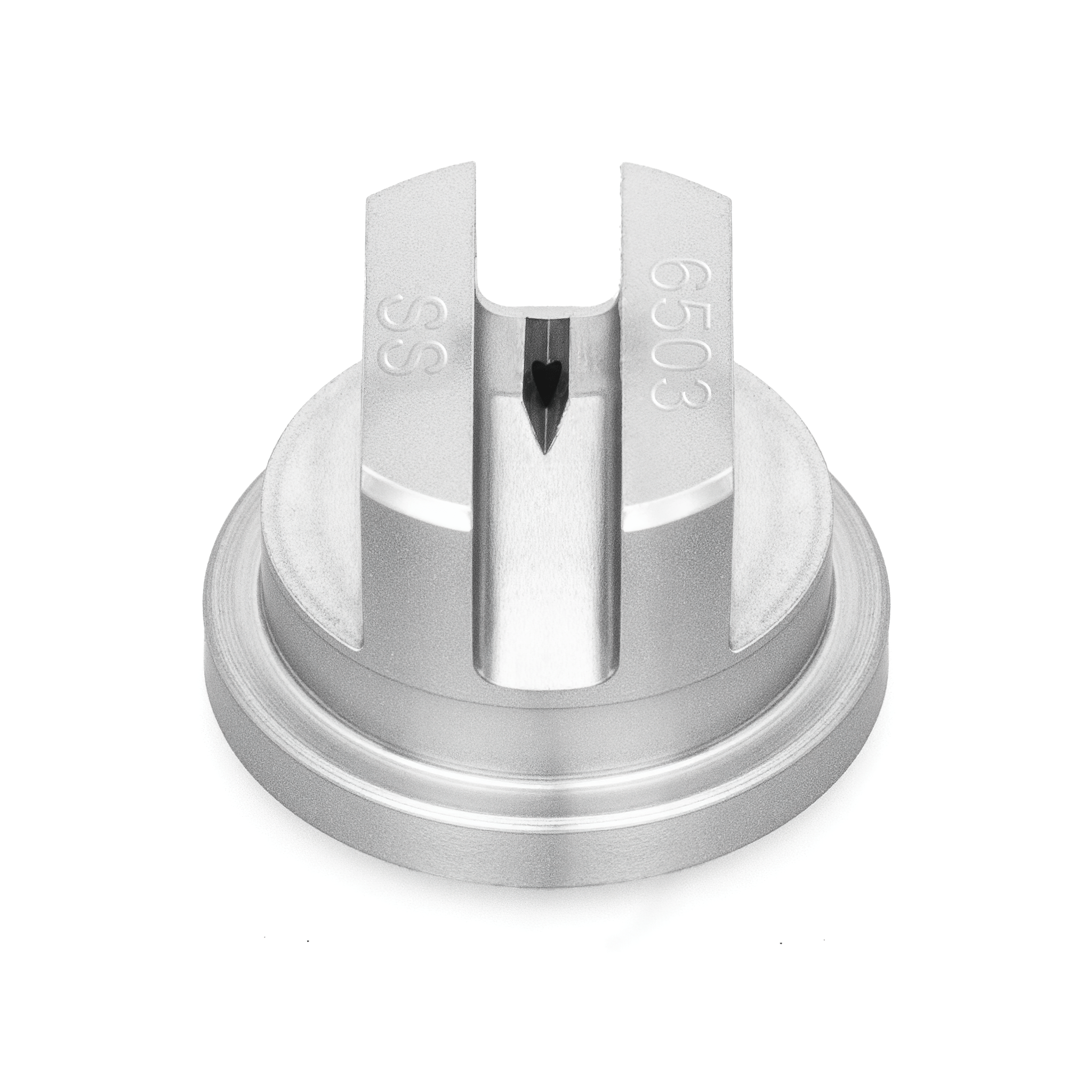

Product Parameters

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 5 |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 1.4 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Equivalent Orifice Diameter (in) | 0.056 |

| Spray Angle at Rated Pressure (PSI) | 80 |

Description

Product Overview

During drying & blow-off on a bakery & confectionery site, plant operators trust the NP3U-8005-316 to deliver consistent and uniform spray coverage essential for product quality and equipment cleanliness. Constructed from 316L stainless steel, the nozzle withstands corrosive environments commonly found in food processing areas. Its precision projet 3x modular unit assembly design enables easy maintenance and exact spray patterns that reduce waste and downtime. Operators report improved drying times and enhanced surface treatment results when integrating this nozzle into their production lines.

Applications

The NP3U-8005-316 plays a critical role in cleaning & washing processes, ensuring thorough removal of residues without damaging delicate surfaces. Its ability to maintain consistent spray angles also supports cooling & quenching operations, which help control material temperatures and improve overall product integrity.

Industries

Sectors such as automotive, steel & metals, and food & beverage frequently select this nozzle for its resistance to wear and chemical exposure during manufacturing & assembly tasks. Additionally, building materials and mining industries benefit from its durability in harsh environments, making it suitable for both continuous and specialty applications.