Product Parameters

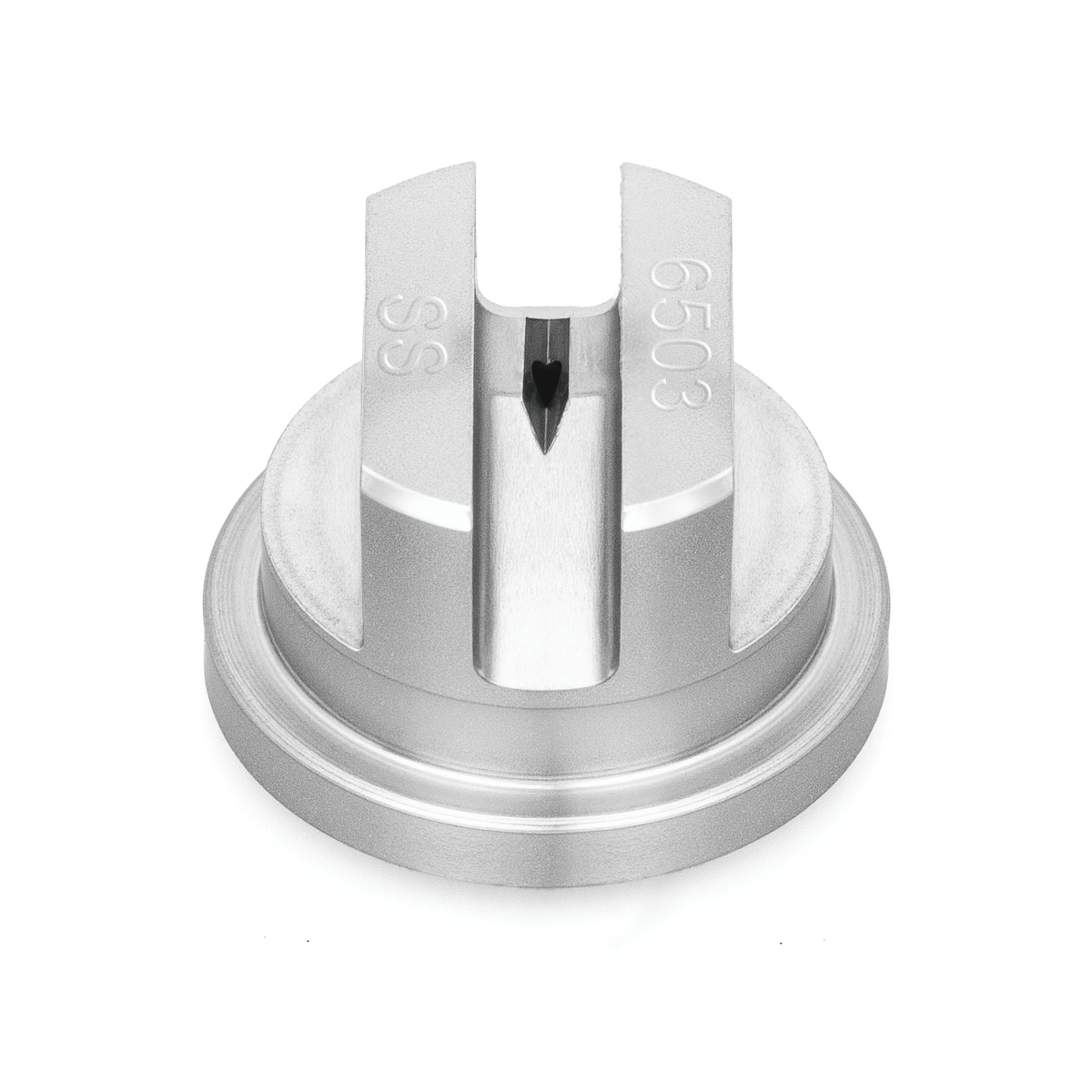

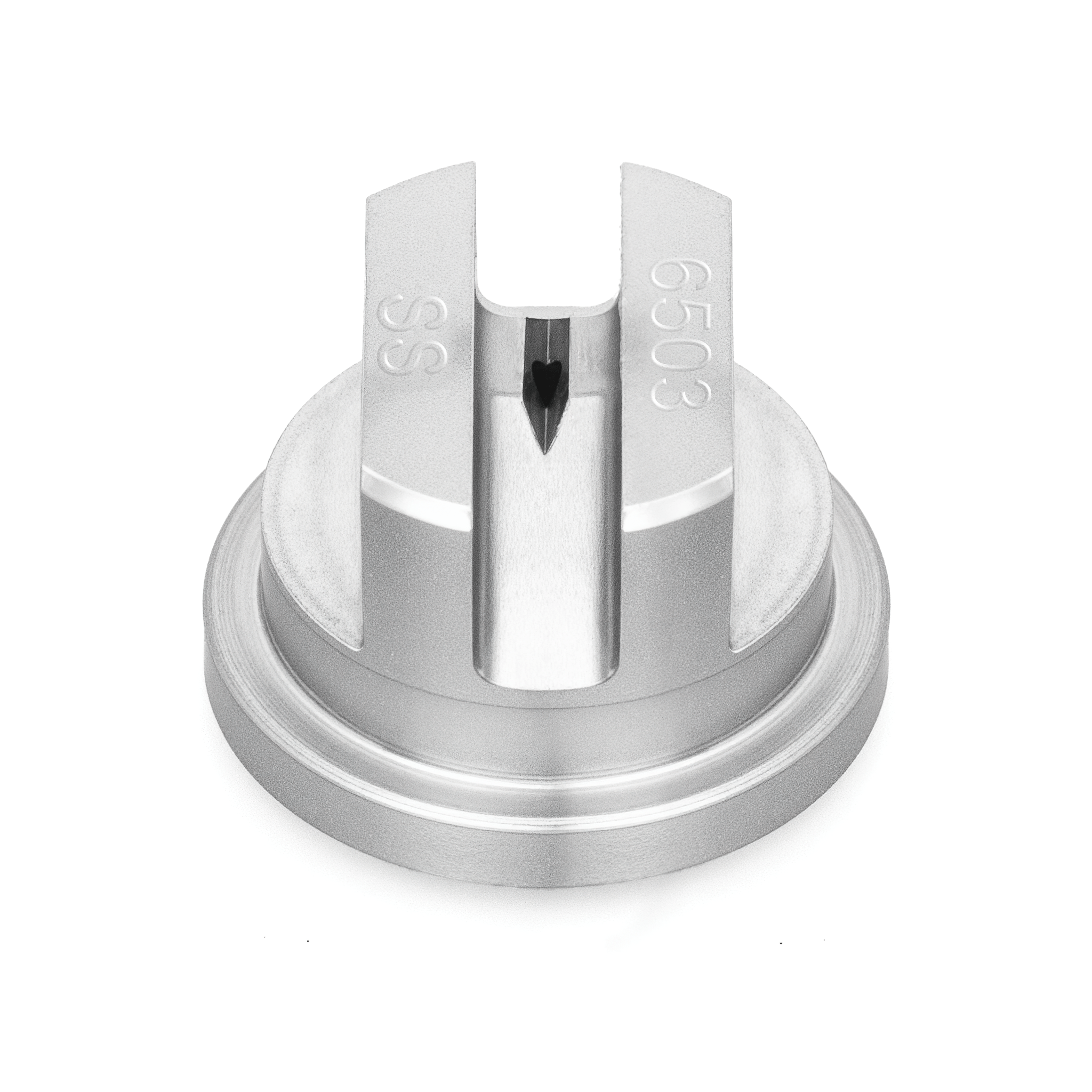

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 4 |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 1.3 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Equivalent Orifice Diameter (in) | 0.050 |

| Spray Angle at Rated Pressure (PSI) | 80 |

Description

Product Overview

Inside the steel & metals line's cooling & quenching stage, a maintenance supervisor relies on the NP3U-8004-316 to deliver a consistent spray pattern that ensures even temperature reduction. Constructed from 316L stainless steel, this modular unit assembly nozzle withstands corrosive environments common in quenching baths. The supervisor calibrates the nozzle for uniform fluid distribution, which directly improves product quality by reducing warping and surface defects during rapid cooling. This precision component integrates easily into existing setups due to its modular design, simplifying maintenance and replacement schedules.

Applications

The NP3U-8004-316 nozzle is frequently employed in cooling & quenching processes to maintain controlled temperatures across metal parts, preventing thermal stress. It also plays a critical role in cleaning & washing operations where uniform spray coverage is necessary to remove contaminants without damaging sensitive surfaces, contributing to smoother downstream assembly.

Industries

Sectors such as automotive, food & beverage, and steel & metals choose this nozzle for its durability and resistance to corrosive media found in processing lines. Its ability to provide uniform spray distribution makes it suitable for use in bakery & confectionery, breweries & wineries, and building materials industries, where precise fluid control directly affects product consistency and equipment longevity.