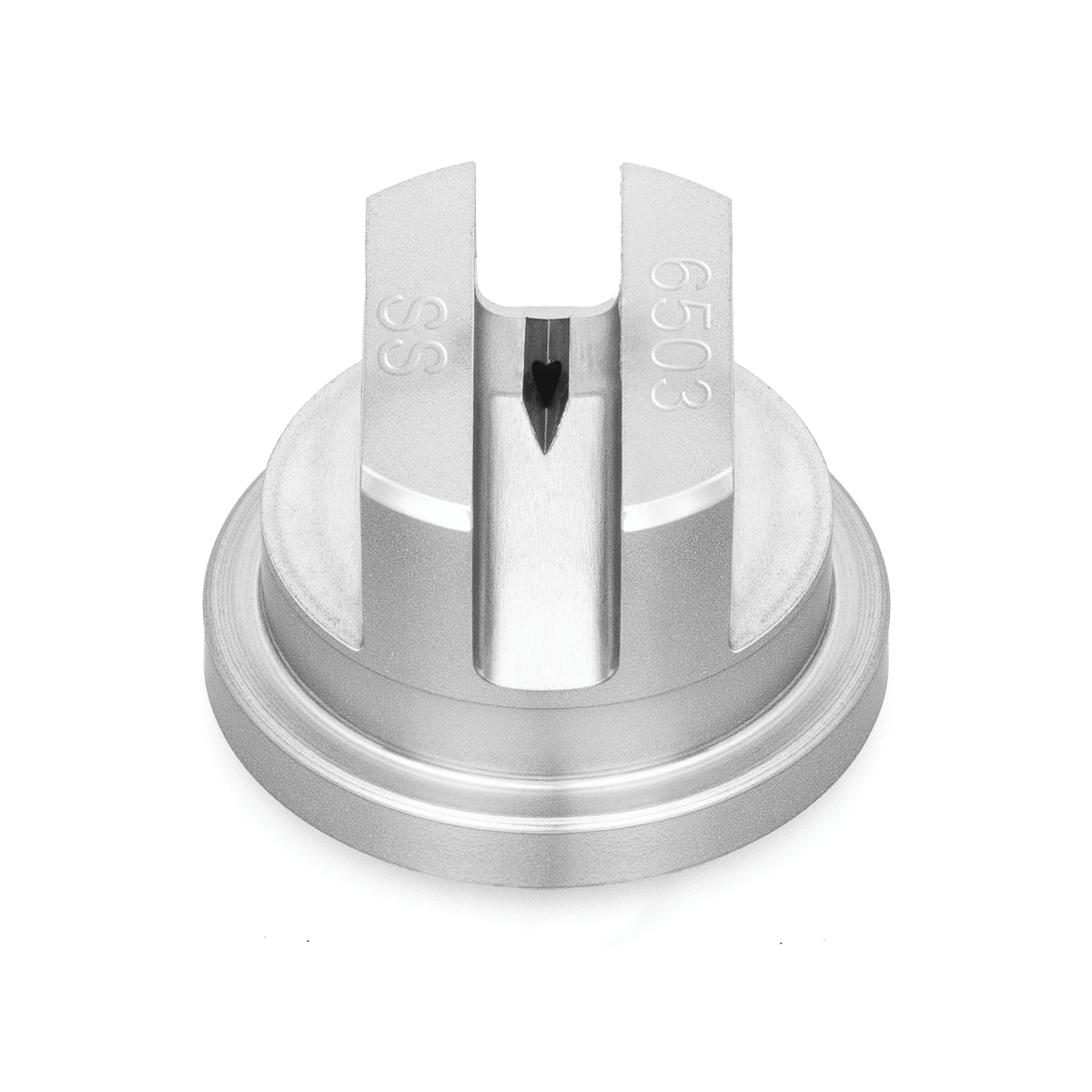

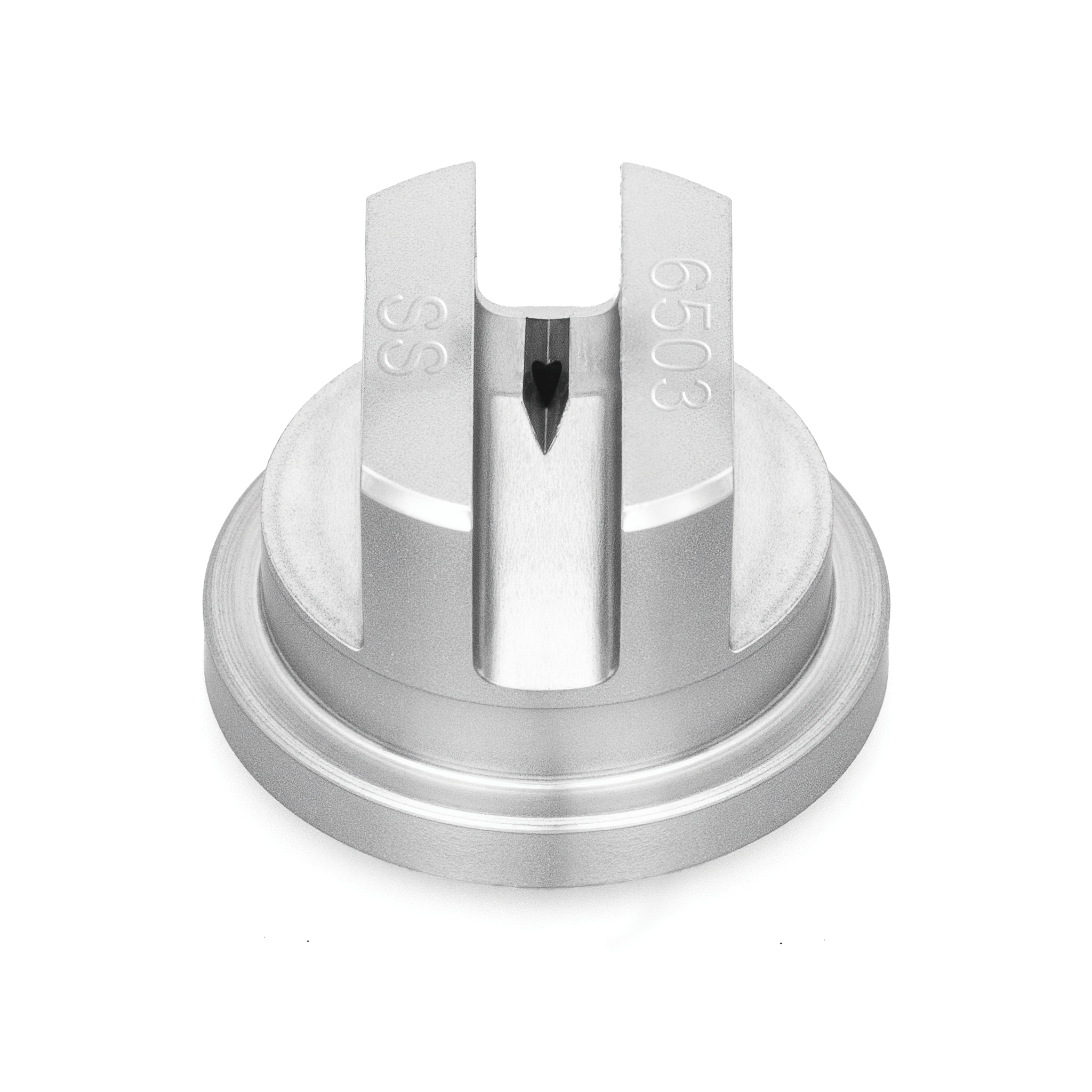

Product Parameters

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 55 |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 1.5 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Spray Angle at Rated Pressure (PSI) | 65 |

Description

Product Overview

Inside the meat & poultry line's coating & surface treatment stage, a process engineer relies on the NP3U-65055-316 to deliver consistent and uniform spray coverage essential for product quality. Crafted from 316L stainless steel, this nozzle withstands corrosive cleaning agents and high temperatures commonly encountered in the production environment. The precision projet 3x modular design enables straightforward maintenance and replacement, minimizing downtime while ensuring exact spray angles and flow rates. This results in reliable coating thickness and reduced material waste throughout the operation.

Applications

The NP3U-65055-316 is frequently employed in cleaning & washing processes where consistent fluid distribution removes residues without damaging sensitive surfaces. Its performance also supports cooling & quenching stages, where precise spray patterns help regulate temperature and prevent thermal stress on components.

Industries

This nozzle finds extensive use across automotive, food & beverage, and steel & metals sectors due to its corrosion resistance and ability to maintain spray integrity under harsh conditions. Additionally, industries such as building materials and mining benefit from its durability and ease of integration into complex assembly and surface treatment systems.