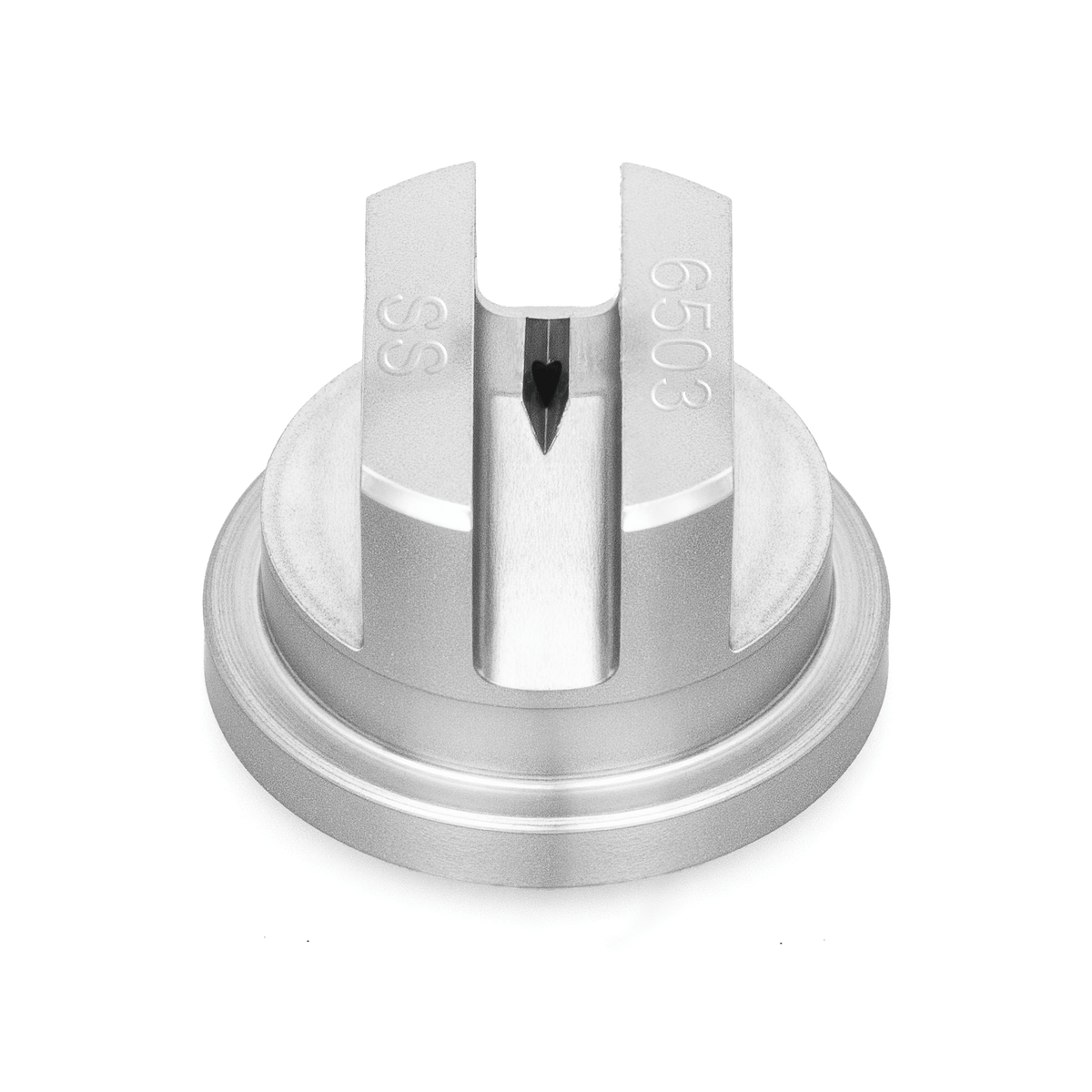

Product Parameters

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 15 |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 2.5 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Spray Angle at Rated Pressure (PSI) | 65 |

| Diameter (in) | 0.032 |

Description

Product Overview

A plant operator in the meat & poultry facility uses the NP3U-65015-316 during cooling & quenching to ensure consistent temperature control across product surfaces. Constructed from 316L stainless steel, this nozzle provides corrosion resistance essential for prolonged exposure to moisture and cleaning agents. Its precision projet 3x modular design delivers a uniform spray pattern, minimizing water and energy consumption while maintaining process stability. Operators rely on this nozzle to reduce thermal shock and improve product quality through controlled cooling cycles.

Applications

During cooling & quenching, the NP3U-65015-316 nozzle supports uniform liquid distribution, which aids in maintaining consistent product temperatures and reducing spoilage rates. In cleaning & washing operations, the nozzle's corrosion-resistant material and spray consistency contribute to effective surface sanitation and equipment maintenance.

Industries

Sectors such as automotive, steel & metals, and food & beverage utilize the NP3U-65015-316 for its robust build and reliable spray characteristics, which meet the demands of harsh environments. Additionally, industries like bakery & confectionery, breweries & wineries, and building materials benefit from its adaptability in processes requiring precise liquid application under varying conditions.