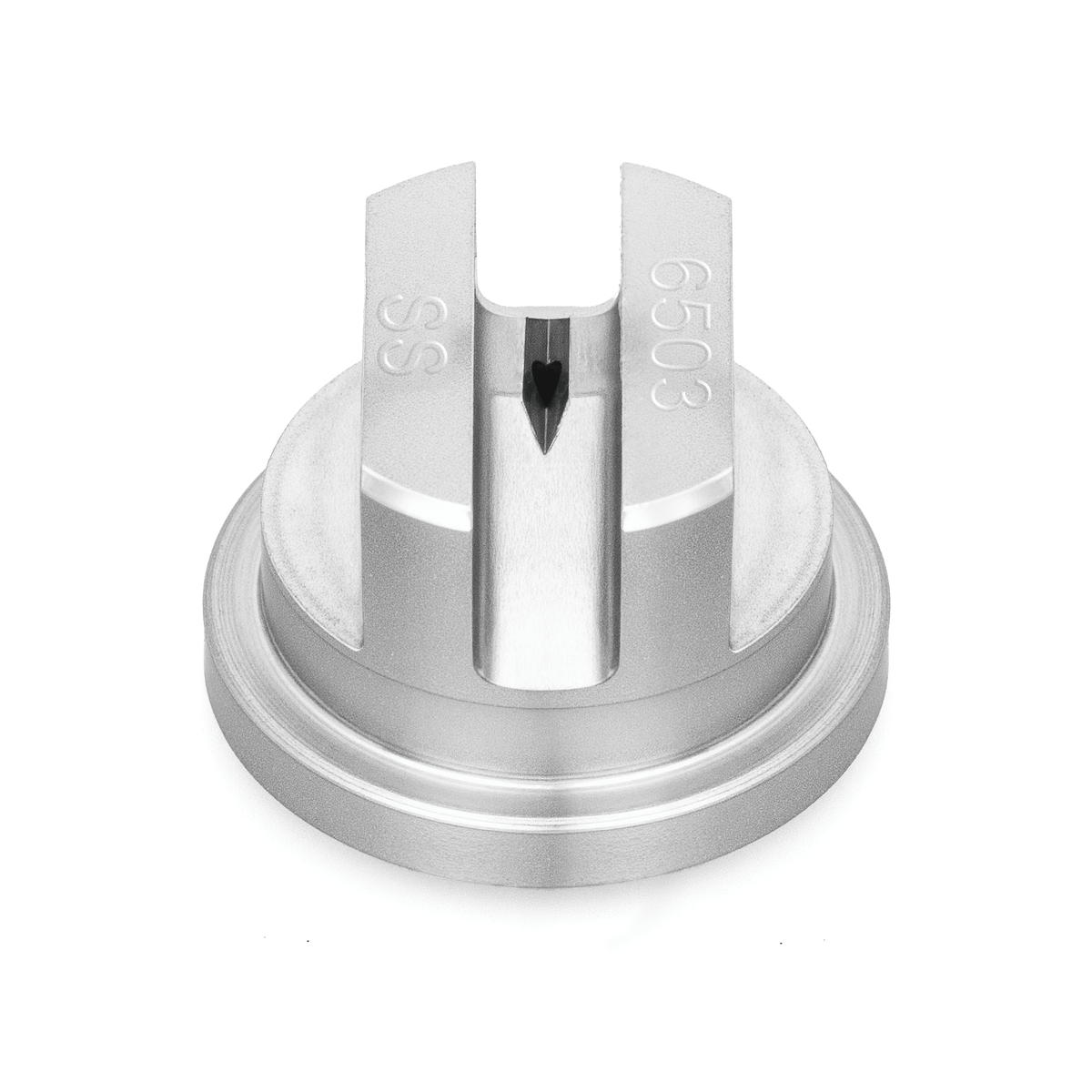

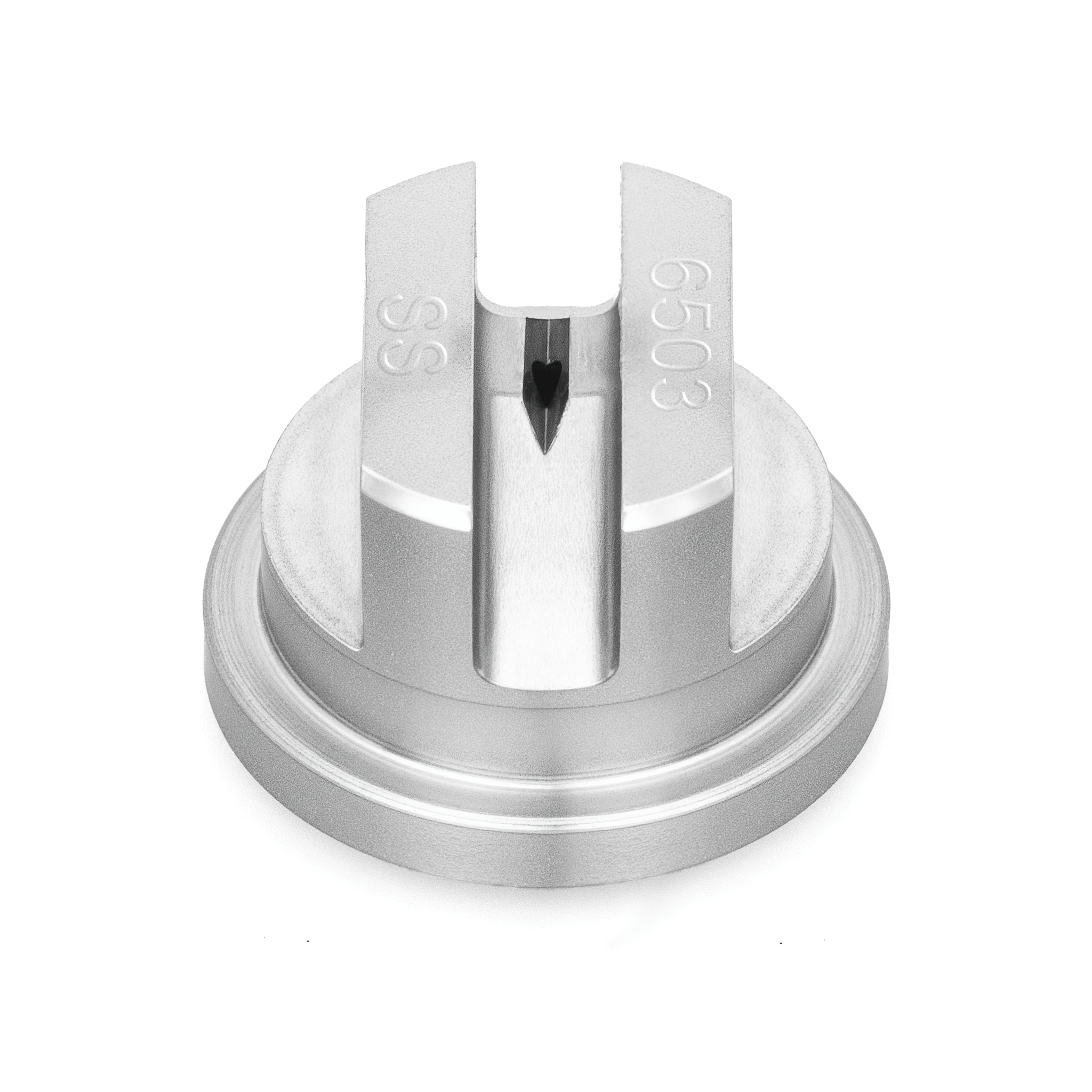

Product Parameters

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 35 |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 1.2 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Spray Angle at Rated Pressure (PSI) | 50 |

Description

Product Overview

Inside the food & beverage line's cooling & quenching stage, a maintenance supervisor relies on the NP3U-50035-316 to deliver consistent spray coverage that maintains product quality and equipment longevity. Constructed from 316L stainless steel, this precision projet 3x modular unit assembly nozzle resists corrosion from washdown chemicals and process fluids. Its uniform spray pattern ensures even cooling rates along the conveyor system, reducing hotspots and minimizing thermal stress. Regular inspections confirm nozzle integrity and spray consistency, supporting uninterrupted production cycles.

Applications

In processes involving cooling & quenching, the NP3U-50035-316 contributes to temperature control critical for product stability and throughput. Additionally, its reliable spray distribution supports cleaning & washing operations, improving surface preparation and sanitation standards downstream.

Industries

Sectors like automotive, steel & metals, and mining select this nozzle for its durability under harsh environmental conditions and its ability to maintain consistent spray patterns during high-volume operations. Food & beverage, bakeries & confectionery, and beverage bottling & packaging benefit from its corrosion resistance and precision in managing temperature-sensitive processes.