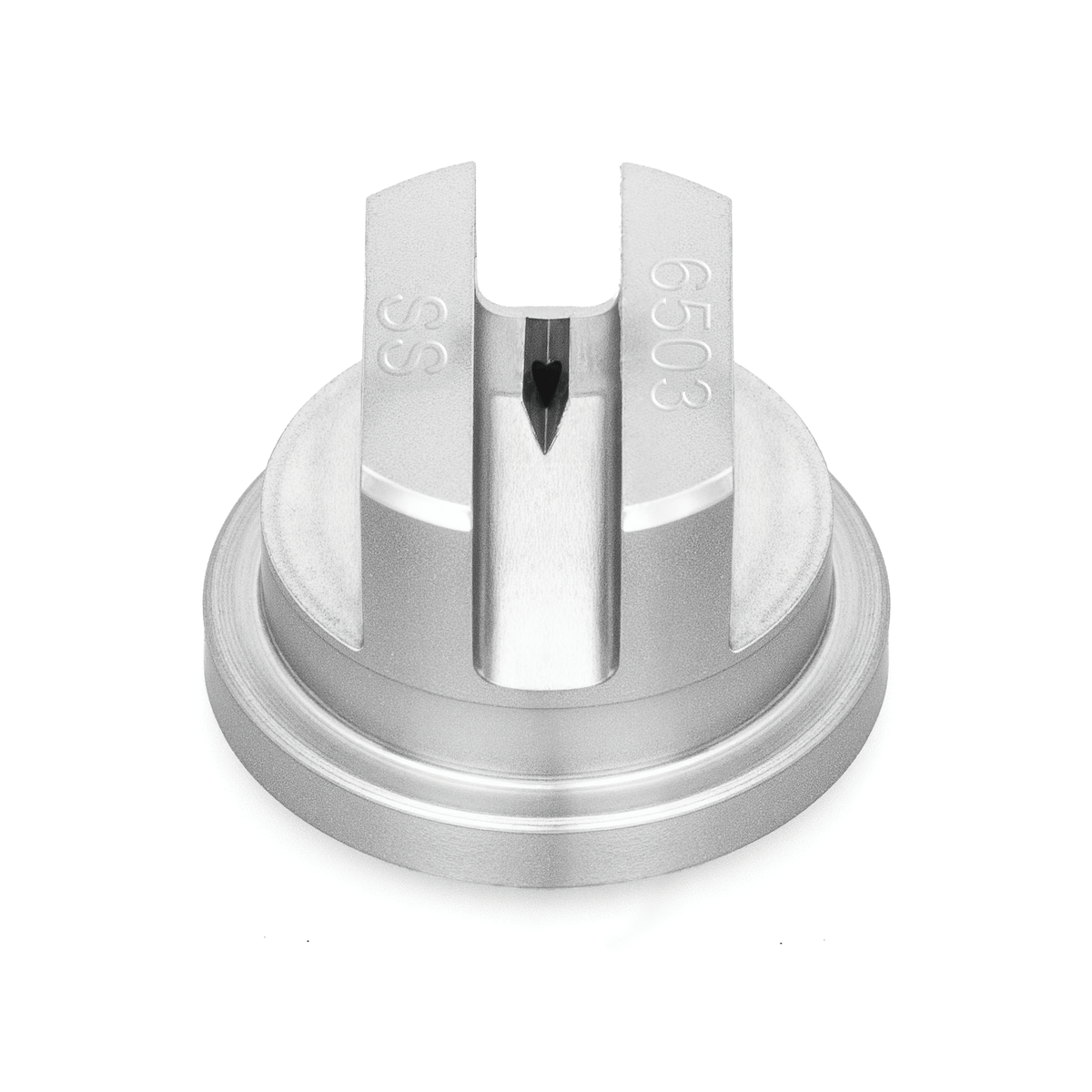

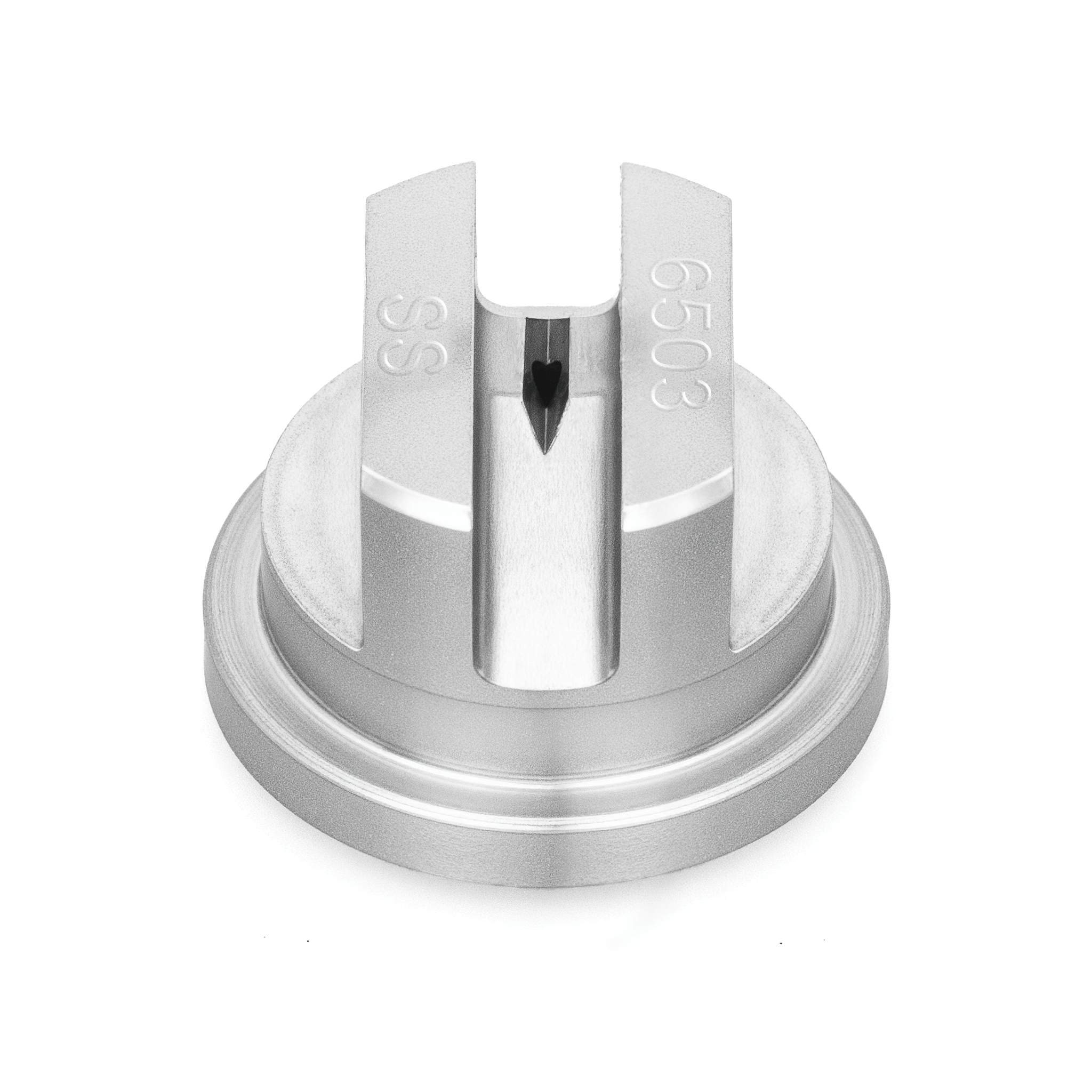

Product Parameters

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 6 |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 1.6 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Spray Angle at Rated Pressure (PSI) | 40 |

| Diameter (in) | 0.061 |

Description

Product Overview

A process engineer in the bakery & confectionery facility uses the NP3U-4006-316 during cooling & quenching to ensure consistent temperature control and product quality. Constructed from 316l stainless steel, this precision projet 3x modular unit assembly nozzle delivers a uniform spray pattern that minimizes hot spots and material waste. Its corrosion-resistant properties enable reliable operation in harsh production environments, maintaining spray performance over extended cycles. The engineer monitors throughput and spray coverage to optimize cooling rates while reducing downtime for maintenance.

Applications

In cooling & quenching processes, the nozzle provides even fluid distribution that enhances heat dissipation and surface conditioning. Additionally, its use in cleaning & washing applications supports quick removal of residues, helping maintain sanitary conditions and improving process efficiency downstream.

Industries

The NP3U-4006-316 is favored across industries such as automotive, steel & metals, and food & beverage due to its durability in demanding environments and adaptability to varied fluid delivery needs. Sectors like manufacturing & assembly and mining also benefit from its corrosion resistance and modular design, which facilitate integration into complex systems requiring reliable spray performance.