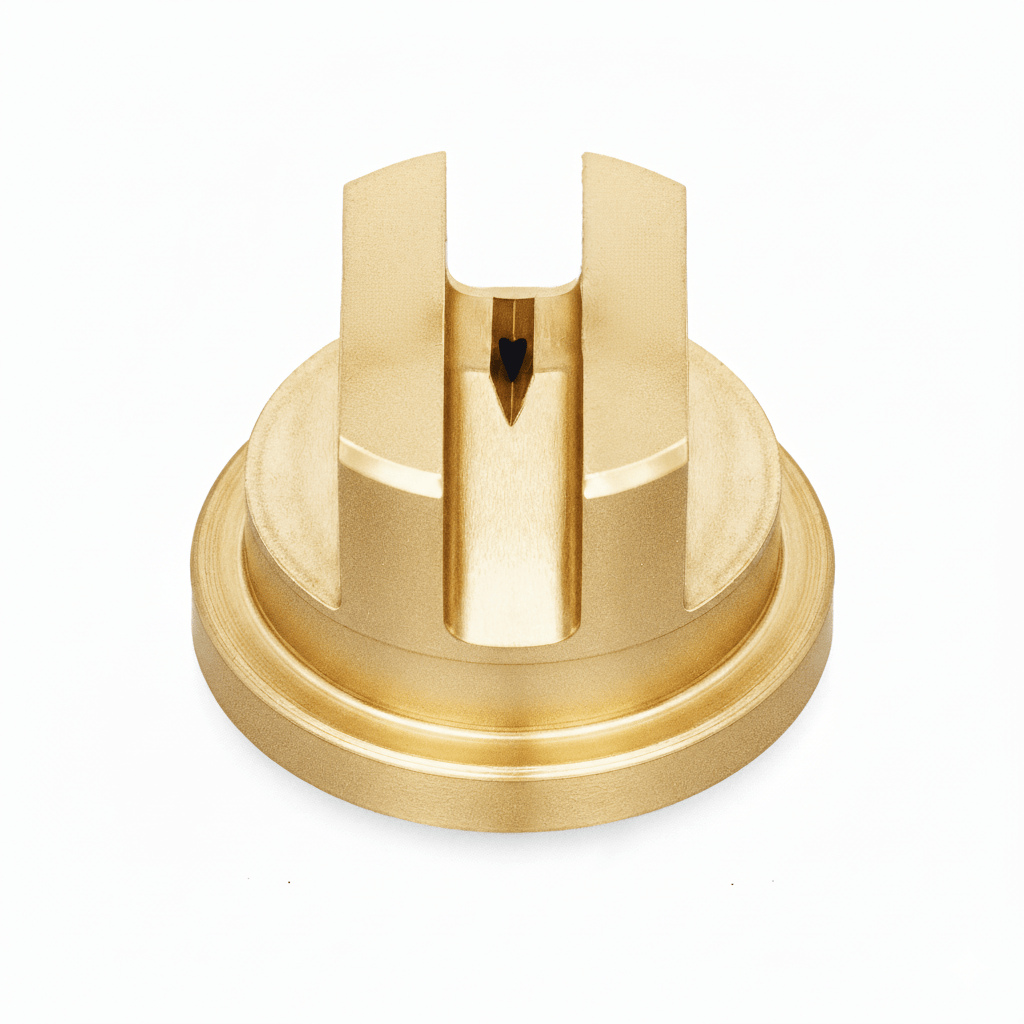

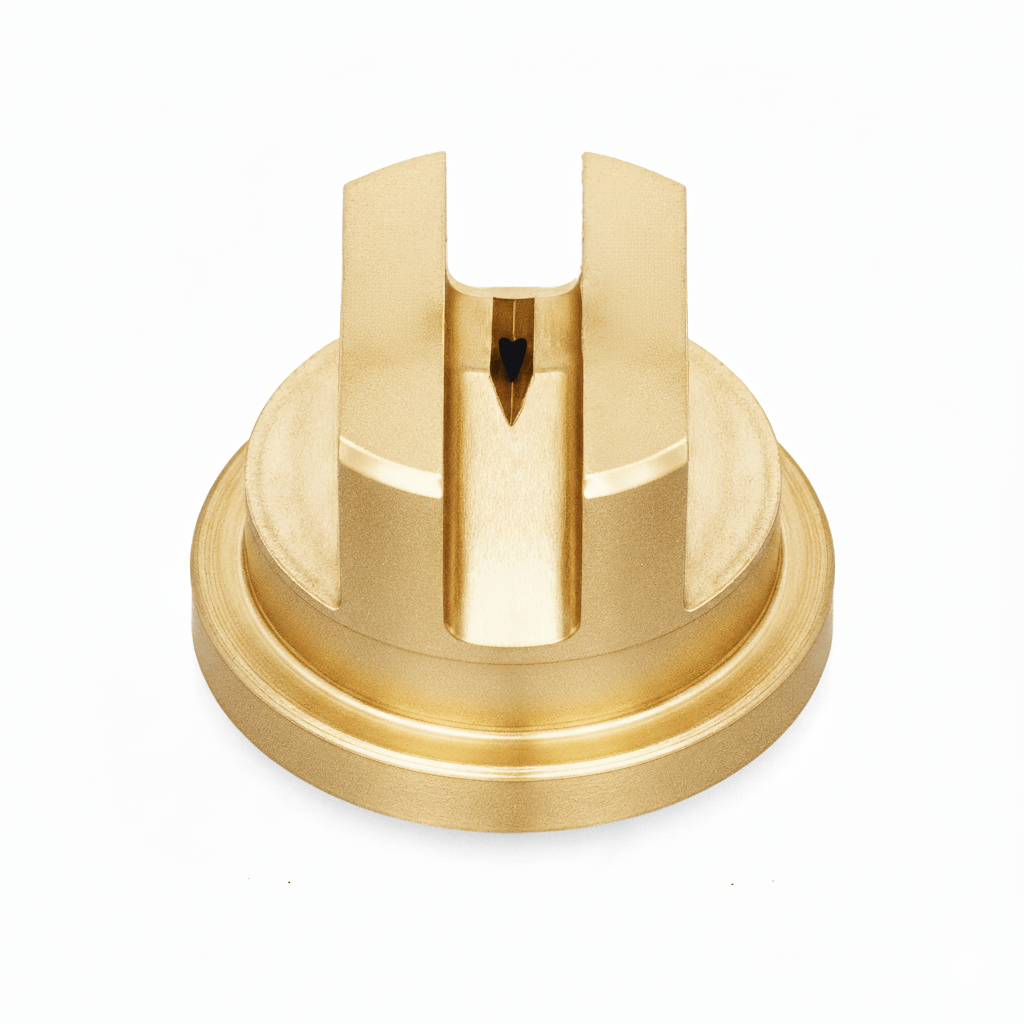

Product Parameters

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 70 |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 5.2 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Equivalent Orifice Diameter (in) | 0.203 |

| Spray Angle at Rated Pressure (PSI) | 25 |

Description

Product Overview

Inside the automotive line's cooling & quenching stage, a maintenance supervisor relies on the NP3U-2570 to deliver consistent performance through its brass construction and uniform spray pattern. The nozzle's precision projet 3x modular design enables targeted application, reducing variation in cooling cycles and minimizing thermal stress on metal components. Operators monitor spray distribution to ensure process consistency, which directly improves part quality and system uptime. Corrosion resistance extends service intervals, supporting reliable operation under harsh environmental conditions.

Applications

In cooling & quenching processes, the NP3U-2570 provides precise fluid distribution to maintain controlled surface temperatures, thereby preventing metal deformation. Additionally, its use in cleaning & washing helps remove residues efficiently, which enhances downstream assembly quality and reduces rework rates.

Industries

Sectors such as automotive, steel & metals, and manufacturing & assembly favor the NP3U-2570 due to its durability in corrosive environments and repeatable spray uniformity. The nozzle's adaptability suits diverse workflows in food & beverage and building materials, where consistent fluid application is critical to maintaining throughput and product standards.