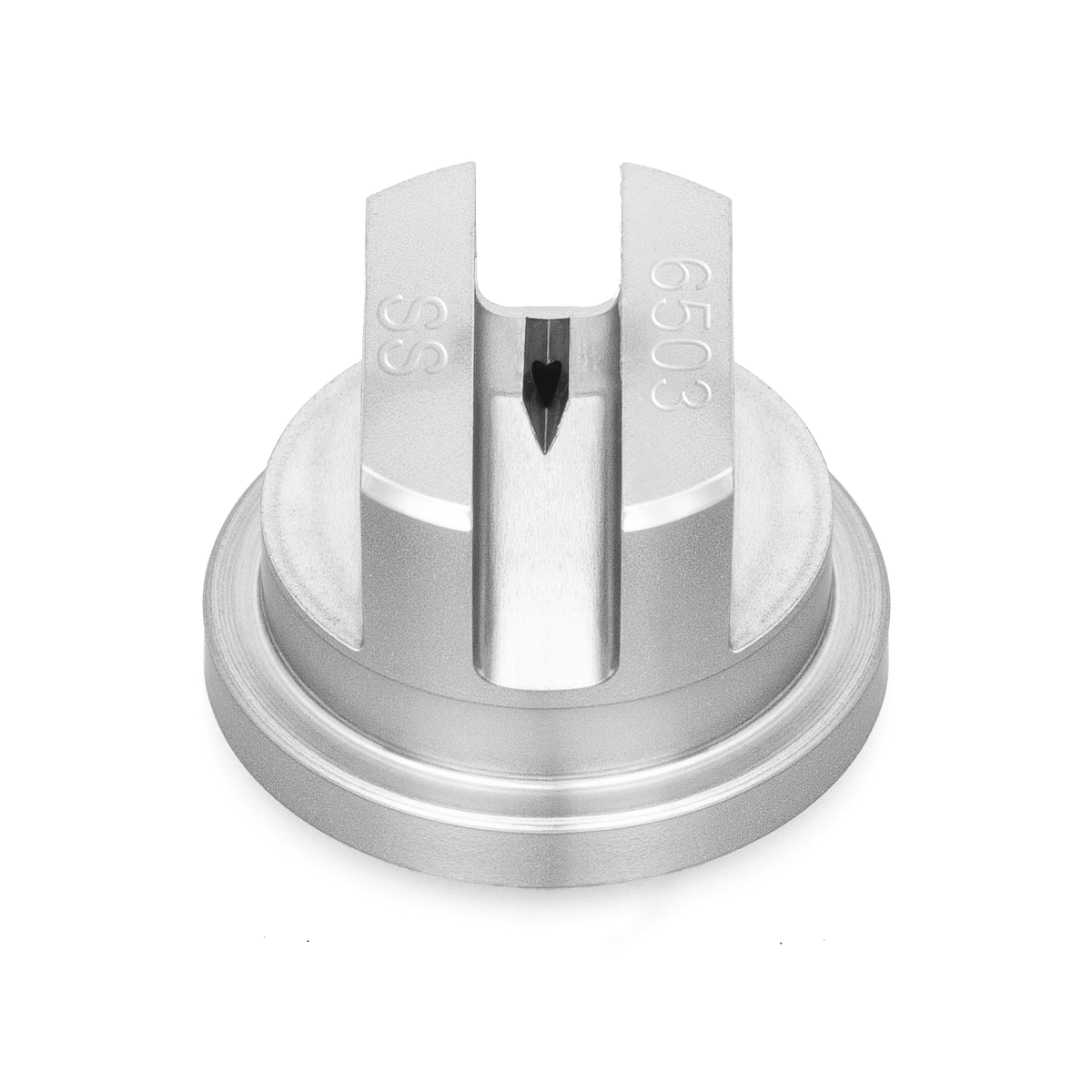

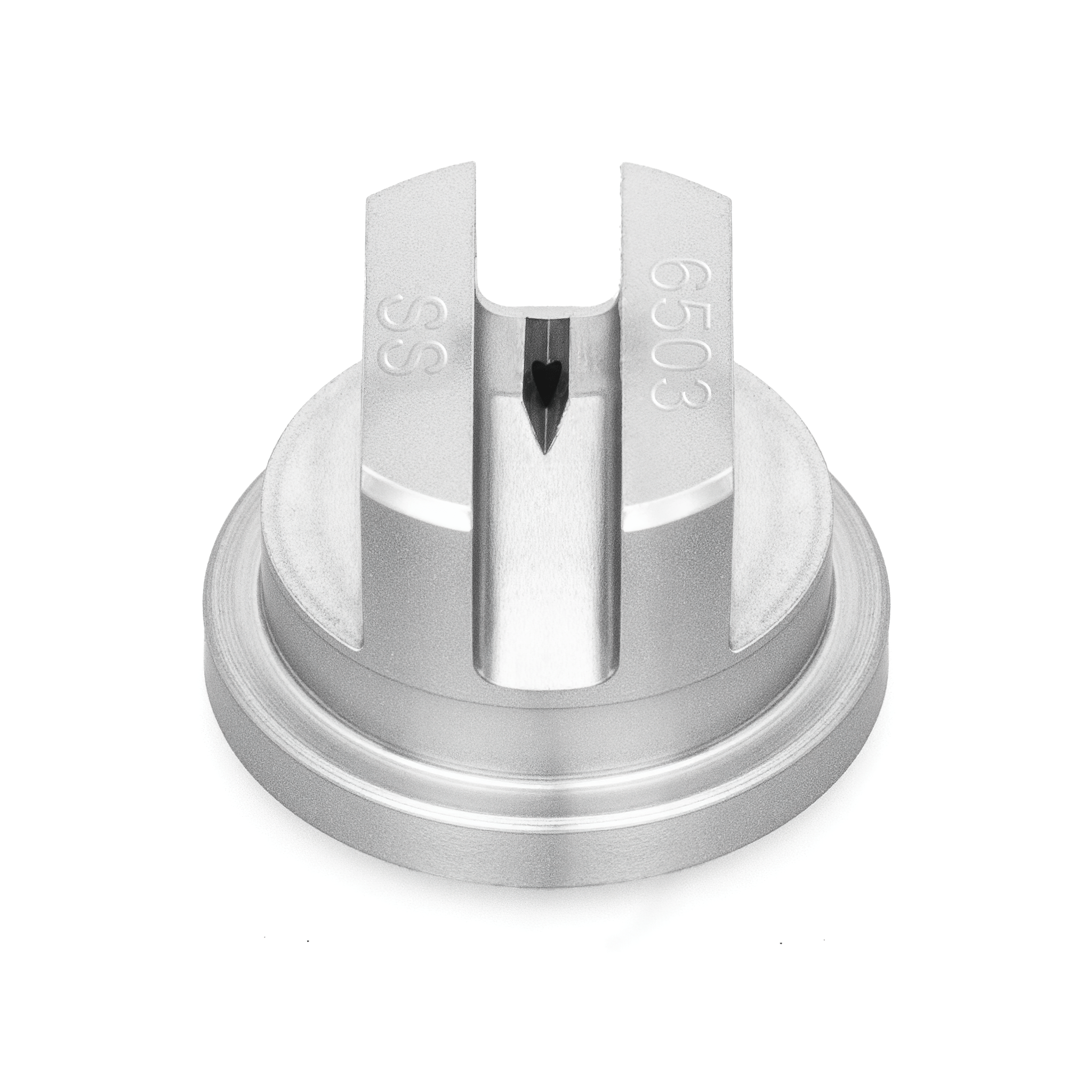

Product Parameters

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 40 |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 3.9 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Equivalent Orifice Diameter (in) | 0.153 |

| Spray Angle at Rated Pressure (PSI) | 25 |

Description

Product Overview

A production technician in the meat & poultry facility uses the NP3U-2540-316 during coating & surface treatment to apply a consistent and uniform spray layer across the assembly line components. Constructed from 316L stainless steel, the nozzle resists corrosion in the facility's humid environment, ensuring long service intervals. The modular 3x design allows for easy maintenance and precise alignment, optimizing coverage while minimizing waste. This results in improved product quality and reduced downtime for cleaning or replacement.

Applications

In cleaning & washing operations, the nozzle delivers a controlled spray pattern that enhances contaminant removal without excessive water use. Additionally, its role in drying & blow-off is critical for efficient moisture removal, directly supporting downstream packaging and inspection processes.

Industries

Sectors such as automotive, steel & metals, and food & beverage industries select this nozzle for its durability and versatility under demanding production conditions. Its corrosion resistance and precise spray control are particularly valued in manufacturing & assembly environments and applications within breweries & wineries, where contamination control and material handling are crucial.