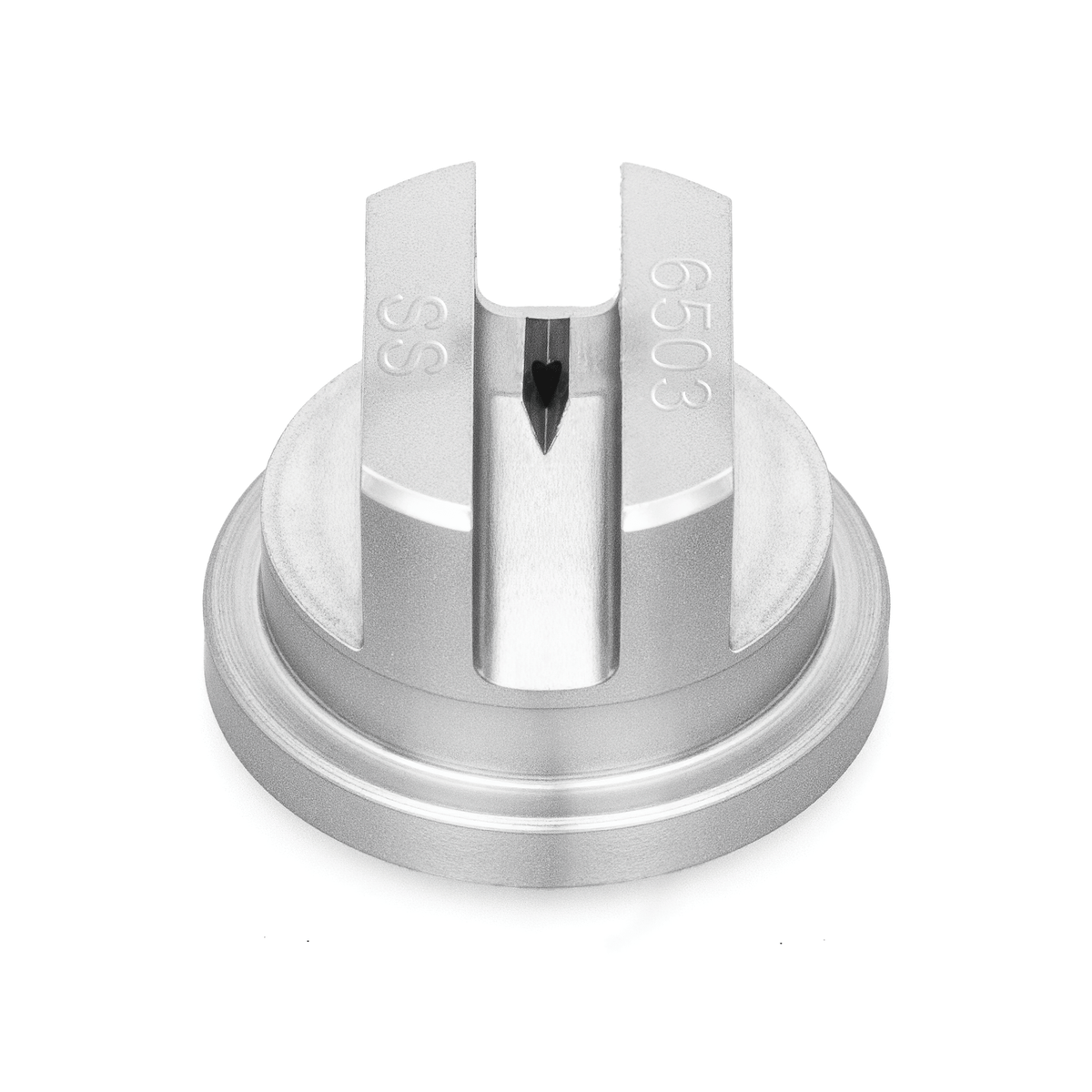

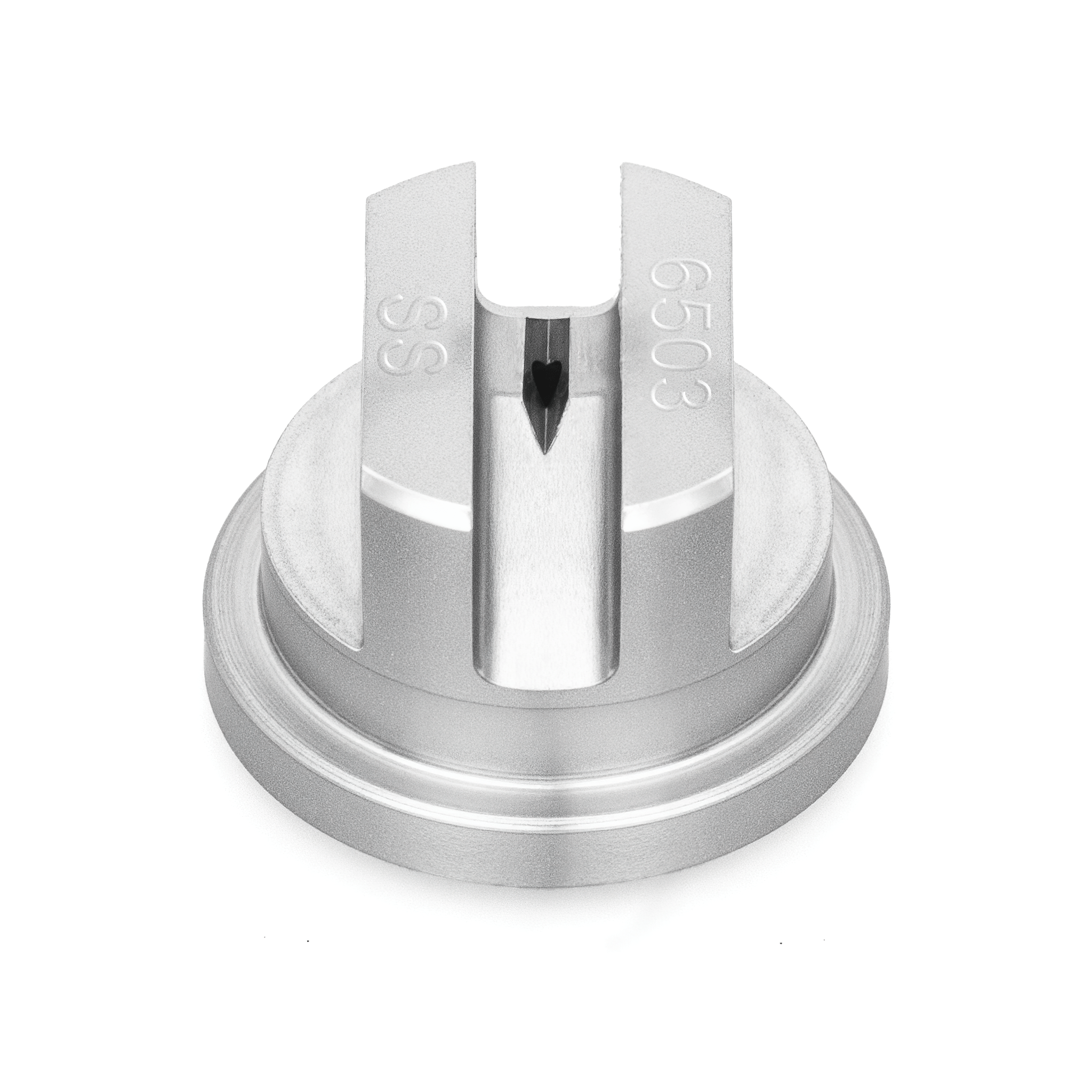

Product Parameters

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 10 |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 2.0 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Equivalent Orifice Diameter (in) | 0.079 |

| Spray Angle at Rated Pressure (PSI) | 15 |

Description

Product Overview

A process engineer in the roofing facility uses the NP3U-1510-316 during humidification to maintain consistent moisture levels essential for material curing and integrity. Constructed from 316L stainless steel, the nozzle resists corrosion in harsh environments, ensuring long-term reliability. The precision projet 3x modular unit assembly design delivers a uniform spray pattern, which enhances coverage and reduces material waste. This controlled application supports tighter process tolerances and minimizes downtime related to equipment maintenance.

Applications

In humidification operations, the NP3U-1510-316 nozzle provides stable and even moisture distribution that helps prevent cracking and dimensional changes in roofing materials. Additionally, its use in coating & surface treatment ensures that applied materials adhere properly, improving the durability and finish quality of the final product.

Industries

Sectors such as automotive, steel & metals, and manufacturing & assembly benefit from the nozzle's corrosion resistance and consistent spray performance, which are critical for both cleaning & washing and surface treatment tasks. Food & beverage and beverage bottling & packaging industries rely on the NP3U-1510-316 for sanitary operations like disinfection & sanitation, where material compatibility and spray uniformity are vital.