Product Parameters

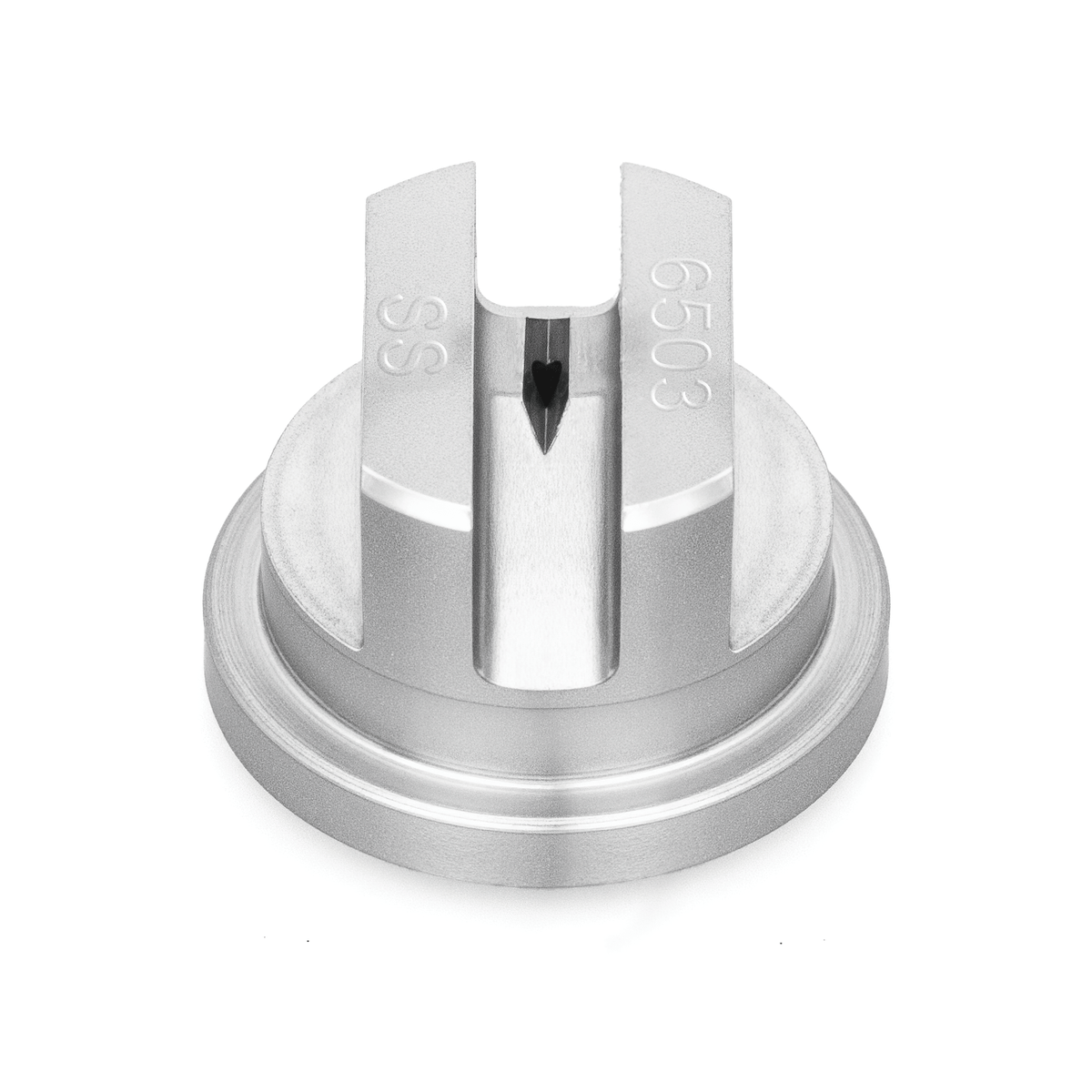

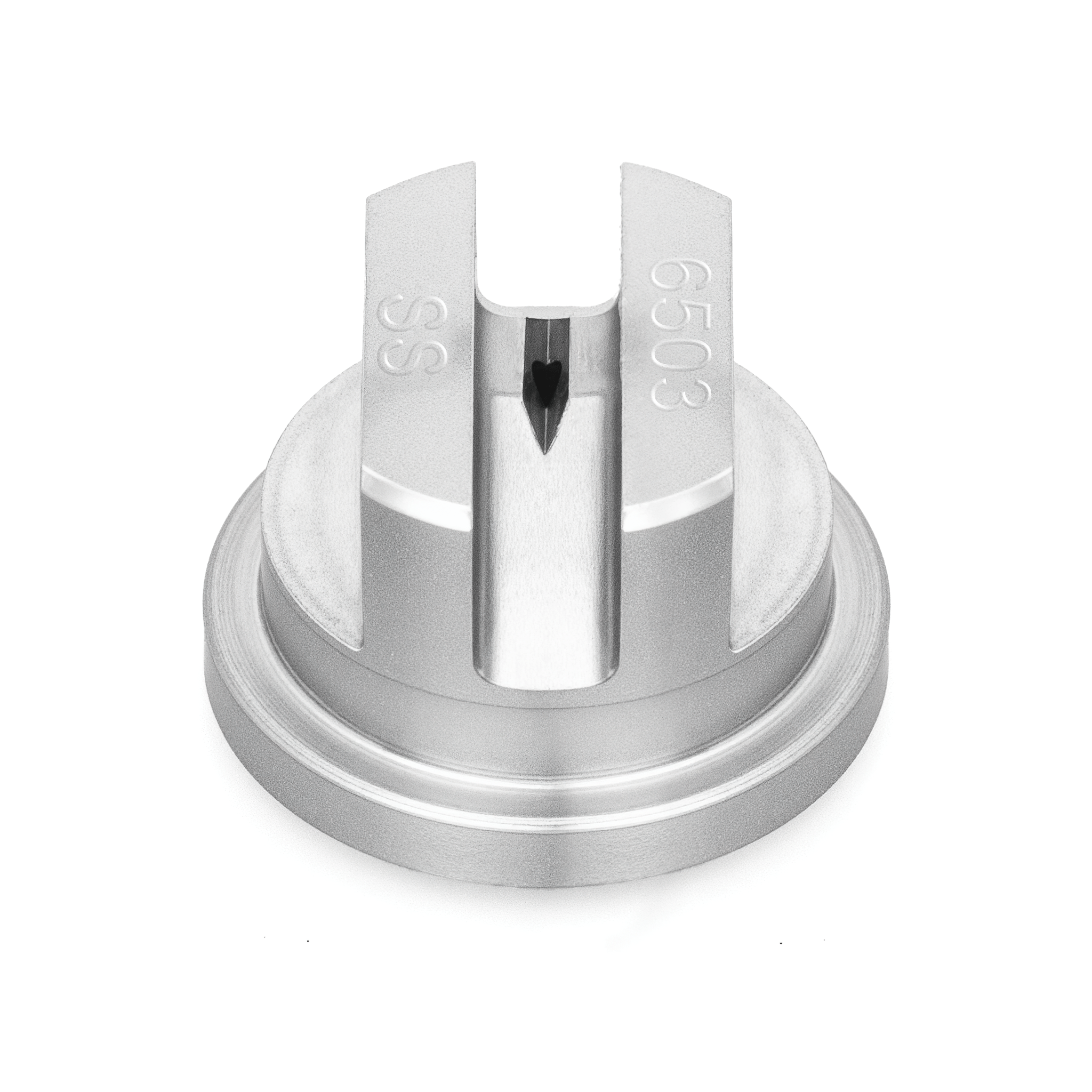

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 5 |

| Material Composition Filter | 303/304 stainless steel |

| Orifice Diameter. Nom. (mm) | 1.4 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Equivalent Orifice Diameter (in) | 0.056 |

| Spray Angle at Rated Pressure (PSI) | 15 |

Description

Product Overview

A process engineer in the food & beverage facility uses the NP3U-1505-SS during cleaning & washing to deliver consistent coverage with a uniform spray pattern. Fabricated from 303/304 stainless steel, this nozzle resists corrosion and maintains performance in harsh chemical environments. By integrating the 3x modular design, the engineer can adjust flow rates precisely, improving sanitation cycles and reducing downtime. This approach ensures effective residue removal while extending the service life of the equipment.

Applications

In cleaning & washing operations, the NP3U-1505-SS provides steady spray distribution that enhances contaminant removal and surface cleanliness. Its use in drying & blow-off steps supports efficient moisture control, helping downstream processes maintain product quality and reduce rework.

Industries

Sectors such as automotive, mining, and steel & metals rely on the NP3U-1505-SS for its durability and adaptability under demanding manufacturing conditions. Additionally, food & beverage, bakeries & confectionery, and beverage bottling & packaging benefit from its corrosion resistance and precise spray control to meet strict hygiene standards.