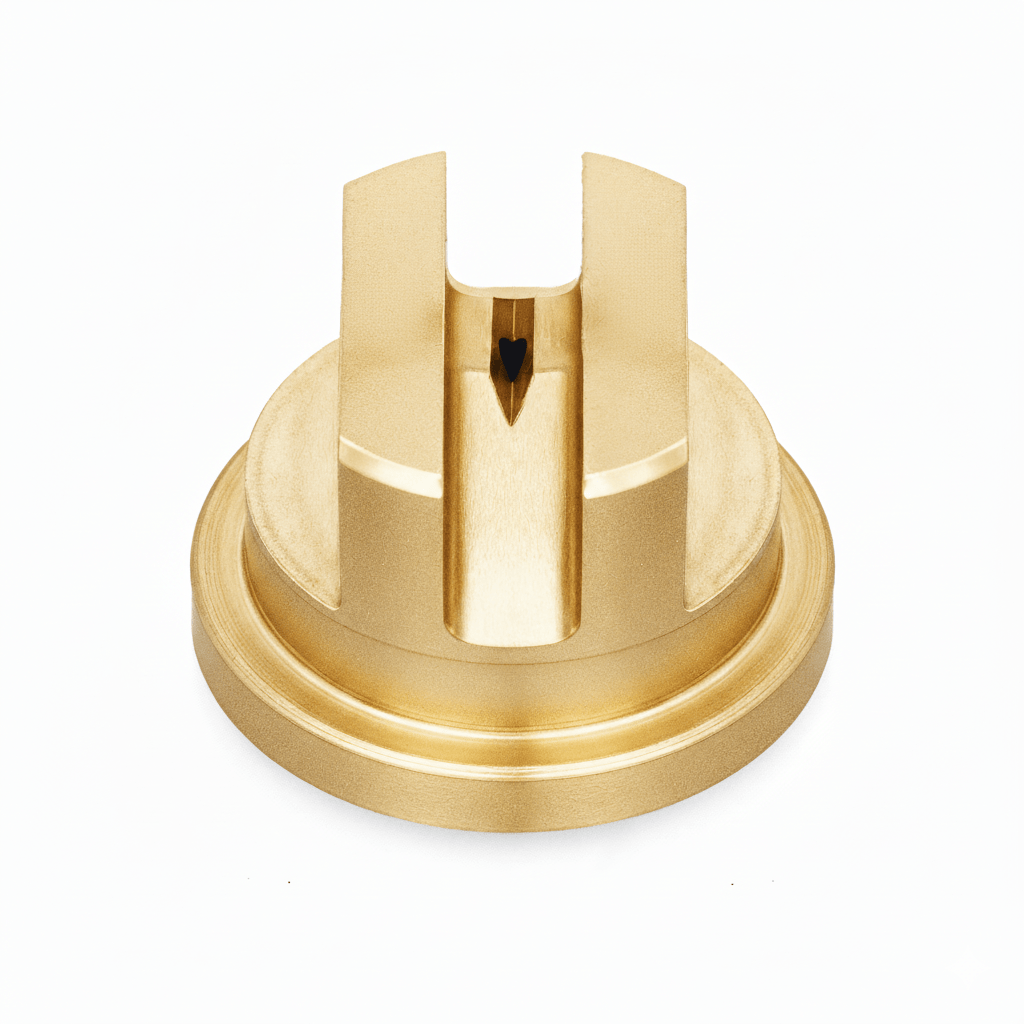

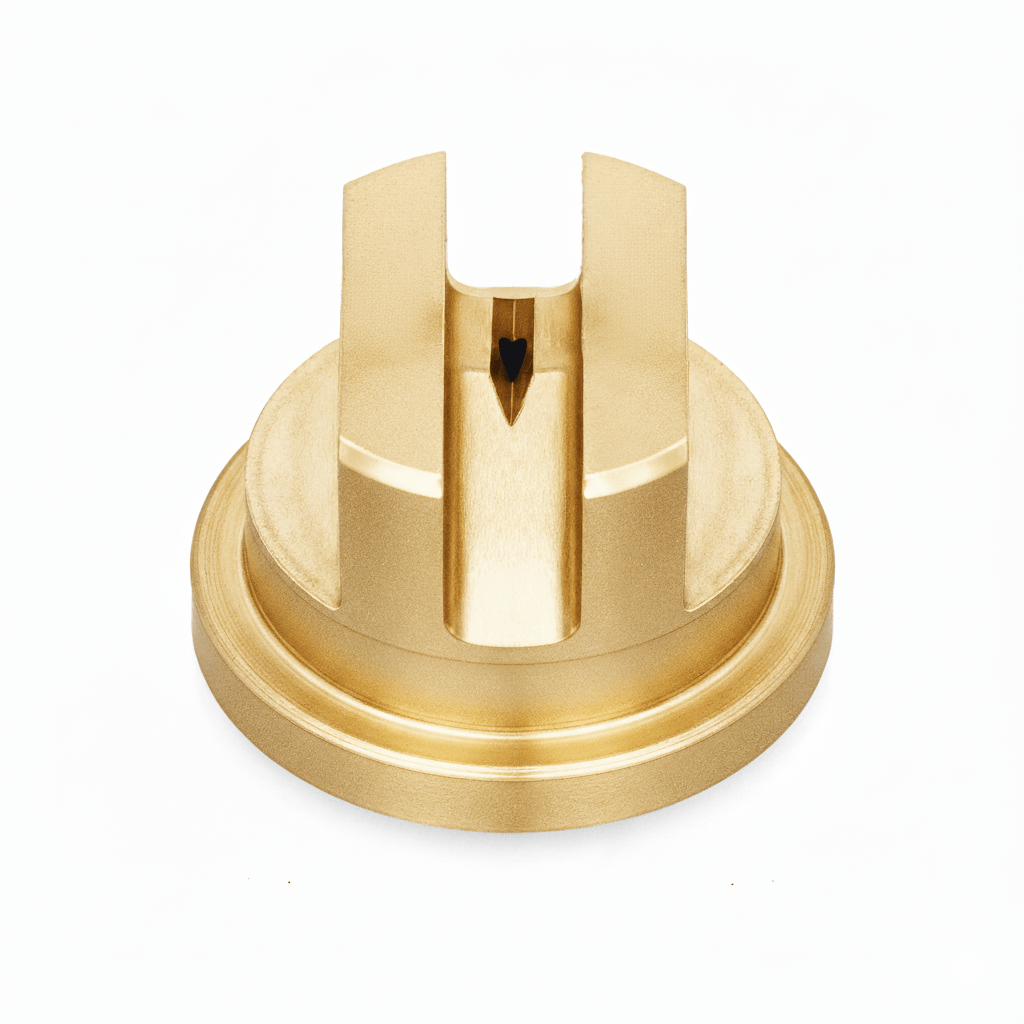

Product Parameters

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 1 |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 0.66 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Equivalent Orifice Diameter (in) | 0.026 |

| Spray Angle at Rated Pressure (PSI) | 110 |

Description

Product Overview

A production technician in the food & beverage facility uses the NP3U-11001 during cooling & quenching to achieve consistent temperature control across conveyor lines. The brass construction ensures durability in corrosive environments common in processing plants. Its precision projet 3x modular design delivers a uniform spray pattern that minimizes product spoilage and maximizes cooling efficiency. By maintaining stable operating conditions, the nozzle supports operational throughput and reduces downtime related to equipment wear.

Applications

In cooling & quenching operations, the NP3U-11001 provides targeted spray distribution that enhances heat dissipation and helps maintain product integrity. Additionally, its reliable performance in cleaning & washing processes ensures effective residue removal while minimizing water consumption and chemical use.

Industries

The automotive and steel & metals sectors rely on the NP3U-11001 for consistent surface treatment and cooling in high-volume manufacturing environments. Its corrosion resistance and spray uniformity also make it well-suited for food & beverage, bakery & confectionery, and beverage bottling & packaging industries, where hygiene and process control are critical.