Product Parameters

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3T |

| Capacity Size | 12 |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (in) | 1.7 |

| Length (in) | 1.469 |

| Hex Size (in) | 9/16 |

| Equivalent Orifice Diameter (in) | 0.029 |

Description

Product Overview

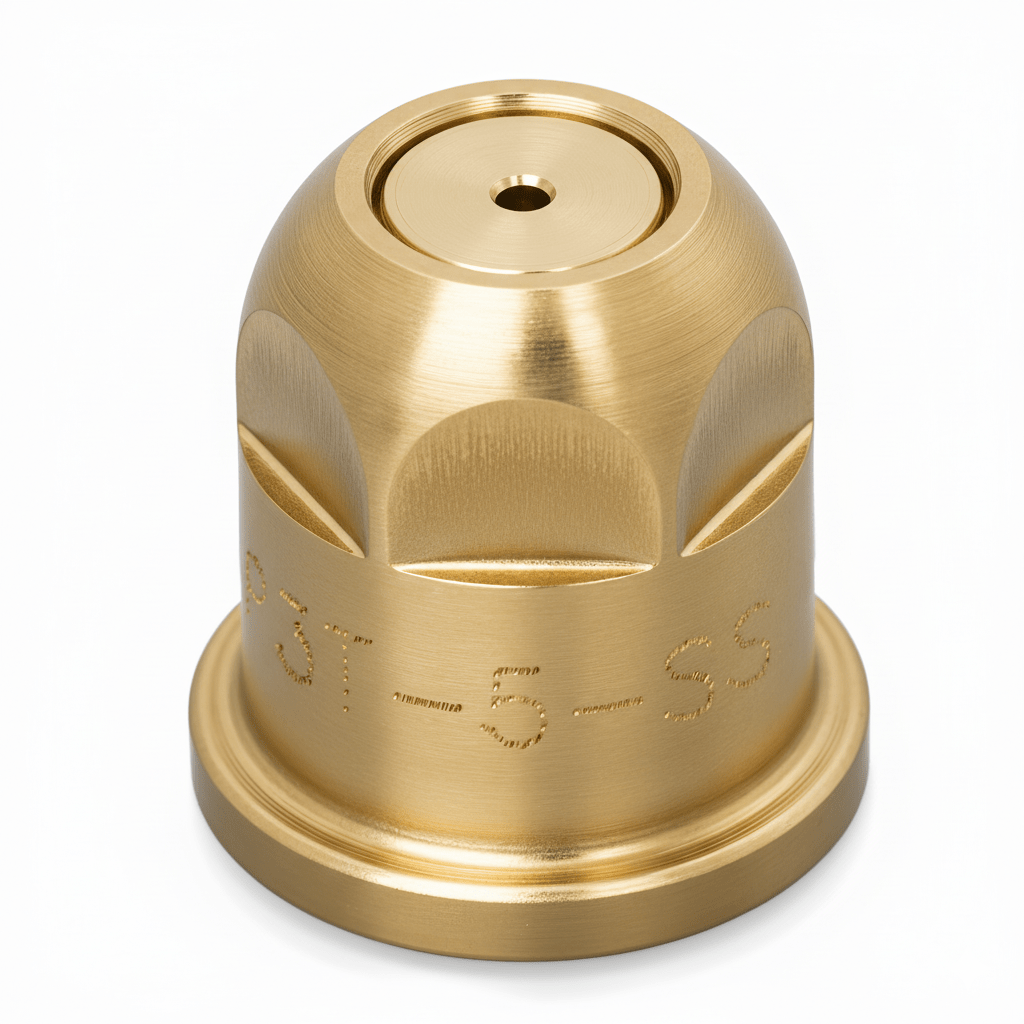

During drying & blow-off on a steel & metals site, quality managers trust the NP3T-12 to deliver consistent results through its precision brass construction and uniform spray distribution. Operators install the modular 3x unit assembly nozzle directly onto production lines, ensuring reliable coverage and corrosion resistance even under continuous exposure to harsh conditions. The nozzle's design facilitates controlled fluid flow, which minimizes waste and maintains surface integrity of metal components throughout the drying process.

Applications

In cleaning & washing operations, the NP3T-12 provides a steady spray pattern that enhances removal of contaminants without damaging sensitive surfaces. Its role in coating & surface treatment helps achieve even application layers, improving adhesion and finish quality in downstream manufacturing processes.

Industries

Sectors such as automotive, mining, and breweries & wineries favor the NP3T-12 due to its durability and adaptability in diverse environments. The nozzle's resistance to corrosion and precise spray capabilities make it well suited for food & beverage, roofing, and manufacturing & assembly industries where consistent spray performance is critical.