Solid stream nozzles might not be the first thing that comes to mind when you think about innovation, but they play a huge role in many fields. From fighting fires to cleaning industrial equipment, these nozzles are designed to handle some pretty tough jobs. In this article, we’ll break down how they work, where they’re used, and why they’re so efficient. Whether you’re in the industry or just curious, there’s a lot to learn about these small but mighty tools.

Key Takeaways

- Solid stream nozzles are specialized tools designed for precision and power in various applications.

- They differ from other nozzles by delivering a concentrated, high-impact stream of liquid.

- Industries like firefighting, agriculture, and industrial cleaning rely heavily on these nozzles.

- Proper maintenance and selecting the right nozzle for the job can significantly improve performance.

- Advancements in materials and smart technology are shaping the future of solid stream nozzles.

Key Features of Solid Stream Nozzles

Solid stream nozzles are designed to create a focused, high-impact stream of liquid. This type of nozzle produces a single, coherent jet that maintains its integrity over long distances. Unlike other nozzle types, it does not atomize the liquid into fine droplets.

Key features include:

- A single exit orifice, which ensures a concentrated flow.

- High-pressure operation to achieve extended reach.

- Minimal spray dispersion, making it ideal for targeted applications.

How Solid Stream Nozzles Differ from Other Types

Solid stream nozzles stand apart from other nozzle designs due to their unique spray pattern and operational characteristics. Here’s a quick comparison:

| Nozzle Type | Spray Pattern | Ideal Use Cases |

|---|---|---|

| Solid Stream | Focused jet | Firefighting, industrial cleaning |

| Fan Spray | Flat, sheet-like | Coating, washing large surfaces |

| Hollow Cone | Circular, hollow | Mixing, atomization |

While fan spray and hollow cone nozzles are great for broad coverage, solid stream nozzles excel when precision and force are required.

Applications Where Solid Stream Nozzles Excel

Solid stream nozzles are versatile and can handle demanding tasks across various industries. Common applications include:

- Firefighting, where a powerful stream is necessary to penetrate flames and cool surfaces effectively.

- Industrial cleaning, especially for removing stubborn residues or debris from machinery.

- Agricultural uses, such as applying liquid fertilizers to specific crops without overspray.

Solid stream nozzles are the go-to solution when precision, power, and efficiency are needed in liquid delivery systems.

Material Innovations in Nozzle Construction

When it comes to building solid stream nozzles, the materials used play a huge role in their performance. Manufacturers often use stainless steel, brass, or even high-grade plastics, depending on the application. Stainless steel is especially popular because it resists corrosion and can handle high-pressure systems without wearing out quickly. Meanwhile, brass is often chosen for its balance of durability and cost. For specialized uses, like handling corrosive fluids, chemical-resistant plastics or alloys might be the go-to choice.

The Role of Exit Orifices in Performance

The exit orifice—the hole where the water or fluid comes out—might seem simple, but it’s actually a finely tuned part of the nozzle. Its size and shape determine the precision and impact of the stream. A smaller orifice creates a more focused, high-pressure stream, while a slightly larger one spreads the flow a bit more. Engineers often test different designs to strike the right balance between power and efficiency.

Here's a quick comparison of orifice sizes and their impact:

| Orifice Size | Stream Focus | Pressure Impact |

|---|---|---|

| Small | Very focused | High pressure |

| Medium | Balanced | Moderate |

| Large | Less focused | Lower pressure |

Impact of Pressure and Flow Rate on Efficiency

Pressure and flow rate are like the heart and lungs of a solid stream nozzle—they need to work together to deliver results. Higher pressure can mean better cleaning or firefighting power, but it also requires a nozzle that can handle the force. Flow rate, on the other hand, affects how much fluid is used. Too much flow can waste water, while too little might not get the job done. The key is to match the nozzle to the task, ensuring both pressure and flow are optimized for the job at hand.

Solid stream nozzles enhance cleaning efficiency by providing a strong impact, essential for effectively removing residues. Medium-impact cleaning is particularly useful for achieving optimal impingement in sanitary tank cleaning applications. Learn more.

Applications of Solid Stream Nozzles in Various Industries

Firefighting and Emergency Services

Solid stream nozzles are a staple in firefighting. Their ability to deliver a concentrated, high-pressure water stream makes them incredibly effective for extinguishing fires quickly, even in challenging conditions. This precision is especially valuable in targeting hard-to-reach areas or controlling the spread of flames. Additionally, these nozzles are often used in emergency services for tasks like clearing debris or flushing out hazardous materials.

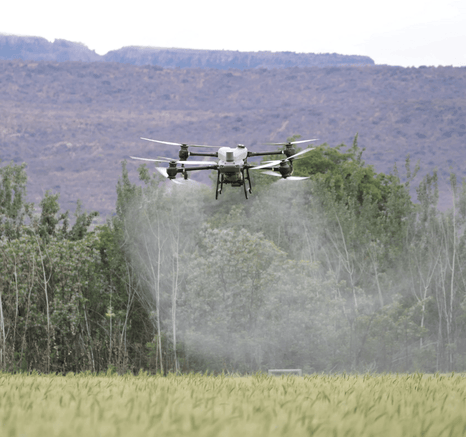

Agricultural and Fertilizer Applications

In the agricultural world, solid stream nozzles serve a variety of purposes. They are often used for irrigation, ensuring water reaches specific areas without excessive spray or waste. Farmers also rely on these nozzles for applying liquid fertilizers directly to the soil, minimizing runoff and maximizing nutrient absorption. Their focused stream ensures that resources are used efficiently, reducing both water and chemical waste.

Industrial Cleaning and Maintenance

Industrial settings demand powerful cleaning solutions, and solid stream nozzles deliver just that. From removing stubborn grime on machinery to power washing large surfaces, these nozzles are indispensable. Their high-impact stream can tackle grease, dirt, and even paint, making them a go-to tool for maintenance teams. Some industries also use them for cleaning pipelines or flushing out debris in confined spaces, where precision and power are key.

Solid stream nozzles excel in scenarios where precision and efficiency are non-negotiable, offering targeted solutions across a range of industries.

Choosing the Right Nozzle for Specific Tasks

Selecting the right solid stream nozzle isn’t just about picking one that looks good on paper. You’ve got to think about what you’re actually using it for. Flow rate and pressure are key—too much or too little, and you’re either wasting resources or not getting the job done. For instance, if you’re working with high-speed cleaning, a nozzle with a focused stream might be your best bet. But if you’re applying liquid fertilizers, a multi-stream option could give you better coverage without damaging crops. Don’t forget to check the material too; stainless steel ones are great for corrosive environments.

Adjusting Spray Patterns for Maximum Efficiency

Solid stream nozzles are pretty straightforward, but tweaking the spray pattern can make a world of difference. Some nozzles allow you to adjust the exit orifice, which changes the flow and pressure. This can be super handy if you’re switching between tasks, like going from washing equipment to applying chemicals. Just remember, a tighter stream means more impact, but it also uses more energy. Finding that sweet spot can save you both time and resources.

Maintenance Tips for Longevity

Keeping your nozzles in good shape isn’t rocket science, but it does take a little effort. Here’s a quick checklist to keep them running smoothly:

- Inspect for clogs or debris regularly, especially if you’re working with dirty water.

- Clean the exit orifice gently—no poking with sharp objects!

- Replace worn parts like seals or gaskets as needed.

- Store them properly when not in use to prevent corrosion or physical damage.

A well-maintained nozzle doesn’t just last longer; it works better, saving you money and hassle in the long run.

Environmental and Economic Benefits of Solid Stream Nozzles

Reducing Water and Chemical Waste

Solid stream nozzles are engineered to deliver a highly focused spray, which means less overspray and fewer wasted resources. This precision minimizes runoff, reducing the environmental impact of chemicals and conserving water. For example:

- In agriculture, targeted spraying ensures that fertilizers and pesticides reach the intended areas without excess seepage into the soil.

- In industrial cleaning, the controlled stream drastically cuts down on water usage compared to broader spray patterns.

- In firefighting, the focused stream optimizes water use, crucial in areas with limited water supply.

Lowering Energy Consumption

Using solid stream nozzles can also lead to noticeable energy savings. Their efficient design reduces the amount of pressure needed to achieve the desired spray force. This means:

- Pumps and motors don’t have to work as hard, extending their operational lifespan.

- Lower energy requirements translate to smaller electricity bills.

- Reduced mechanical strain on equipment decreases the likelihood of costly breakdowns.

Cost Savings Through Efficient Design

The economic benefits of solid stream nozzles go beyond just energy savings. Their durability and efficiency contribute to long-term cost reductions. Here’s how:

| Benefit | Impact |

|---|---|

| Durability | Longer lifespan reduces replacement costs. |

| Precision | Less material waste saves money. |

| Lower Maintenance | Reduced downtime and repair expenses. |

By combining environmental responsibility with economic efficiency, solid stream nozzles are a smart choice for industries looking to optimize performance while cutting costs.

Future Trends in Solid Stream Nozzle Technology

Advancements in Nozzle Design and Materials

The future of solid stream nozzles lies in precision engineering and innovative materials. Manufacturers are increasingly exploring lightweight thermoplastics and corrosion-resistant metals to extend nozzle lifespan and improve performance. Injection molding and 3D printing are also enabling more intricate designs, allowing for better control over flow rates and spray patterns. These technologies are paving the way for nozzles that are not only more durable but also tailored for specific applications.

Integration with Smart Systems for Precision

Smart technology is reshaping how nozzles operate. Many modern systems now feature sensors and automated controls that adjust spray patterns in real-time based on environmental conditions or the task at hand. This level of automation ensures minimal waste and maximum efficiency. For example, in metal surface preparation, automated nozzle systems can fine-tune spray angles and droplet sizes to achieve consistent results without manual intervention.

Emerging Applications in New Industries

Solid stream nozzles are finding their way into industries beyond their traditional uses. From medical sterilization processes to advanced manufacturing, these nozzles are being adapted for tasks requiring high precision and reliability. As industries demand more specialized tools, the versatility of solid stream nozzles will likely expand further, opening doors to applications we haven’t even considered yet.

"The next decade will be about balancing innovation with sustainability, ensuring that every drop of liquid serves its purpose efficiently."

Conclusion

Solid stream nozzles have proven to be a reliable tool across a variety of modern applications. From firefighting to agriculture, their ability to deliver focused, high-pressure streams makes them incredibly versatile. While no single nozzle design fits every scenario, understanding the specific needs of a task and matching it with the right nozzle can make a world of difference. As technology continues to improve, these nozzles are becoming even more efficient and adaptable, offering better performance and resource savings. Whether you're looking to tackle a fire or optimize irrigation, solid stream nozzles remain a practical and effective choice.